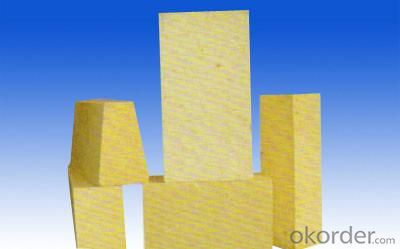

Silica Brick - Lightweight

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 PCS

- Supply Capability:

- 50000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden pallet |

| Delivery Detail: | 20days after receiving the advance |

Specifications

Light Weight Silica Brick

1. High refractoriness

2.High porosity

3.Good thermal shock stability

4.Best price, high quality

Brief description

1. High refractoriness

2.high porosity

3.good thermal shock stability

Main Technical Property Indexes

Item | |

SiO2≥ | 91 |

Refractoriness℃ | 1670 |

RUL(0.2MPa)0.2MPa℃ | 1560 |

Apparent Porosity%≤ | 45 |

CCS Mpa≥ | 3.5 |

Density g/cm3≤ | 1.2 |

Typical Application

Lightweight silica brick is mainly used for thermal insulation or reduce weight without direct contact with molten material, gas is not subject to erosion, don't suffer from temperature leaps kiln parts. Use at high temperatures, can not contact with alkaline refractory materials. According to the material is qualitative different, its highest use temperature at 1200 ~ 1550 ℃.

Advantage of Light Weight Silica Brick

Lightweight silica brick is lightweight refractory with silicon dioxide more than 91%, the volume density of 1.2 g/cm3 .Refractoriness and refractoriness under load and the composition of the same common silica brick. But due to the porosity, so the compression strength and slag resistance, corrosion resistance and other than ordinary silica brick, and thermal shock resistance is improved.

- Q: Physical solid waste disposal

- Reduce crack production and improve yield. The amount of addition is related to the shape and weight of the brick. The bricks can be added to 20% weight less than 25kg; bricks above 25kg can be added to 30%; for the specific type of brick can be added 30%. into waste silica brick should pay attention to this problem

- Q: Common bond brick?

- Manufacturing for silica brick binder hi-li sulfate pulp waste liquid and lime milk. When lime milk is used as a bond, it acts as a plasticizer. To increase the strength of lime brick in the drying process, as mineralizer in the firing, promote the transformation of quartz.

- Q: The introduction of silica brick

- The characteristics of silica brick:Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.The use of silica brick:Mainly used for masonry brick oven carbonization chamber, a combustion chamber and a partition wall, glass furnace and kiln roof, pool wall, high temperature hot blast furnace, glass furnace, load-bearing pool wall, hot blast stove, baking furnace of carbon bearing part of high temperature furnaces etc.. Rongsheng with refractory

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Clay brick features good thermal shock resistance and low price, but high temperature performance is not well integrated, and the long-term use temperature is not higher than 1300 degrees. It is widely used in low temperature parts of various kilns.

- Q: What is acid refractory?

- Acid refractory material usually refers to refractories with SiO2 content greater than 93%. Its main characteristic is that it can resist acid slag corrosion at high temperature, but it is easy to react with alkaline slag.

- Q: The United States of our brick anti-dumping duties?

- . According to the relevant legal procedures, the United States International Trade Commission will make a final ruling on the anti dumping industrial injury before January 6, 2014, if an affirmative determination, the U.S. Department of Commerce will be involved in product release tax anti-dumping order.

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- Brick, high thermal conductivity has been greatly improved in terms of morphology, crystal structure, physicochemical index. The structure and morphology of high thermal conductivity of silica brick,Structure and morphology of high thermal conductivity and the traditional brick brick magnified 20 times were compared, high thermal conductivity silica pore size distribution is more uniform and finer.

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.

- Q: High temperature refractory material?

- Special materials often use AZS brick (i.e. corundum brick), corundum brick, magnesia chrome bricks, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials. Insulation refractories are often used diatomite products, asbestos products, insulation board. Unshaped refractories are often used refractory castable, refractory clay, refractory ramming material, refractory plastic and fettling material, fire resistance, gunning, refractory cast material, fireproof coating, lightweight refractory castable, gun mud.

- Q: Such purpose and scope please give me detailed points thank you

- Acid refractory brick is mainly composed of tridymite and cristobalite and quartz and a small amount of residual glass phase.

Send your message to us

Silica Brick - Lightweight

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 PCS

- Supply Capability:

- 50000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords