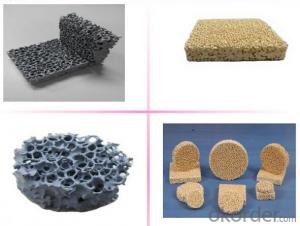

SIC Ceramic Filter Plate for Foundry Filtration

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Silicon Carbide Ceramic Foam Filter work at more than 1500 Degree Celsius, filter moten iron and copper in related casting.

Silicon Carbide Ceramic Foam Filter

Ceramic Foam Filter is the third generation filter, compared with traditional filtering materials(ceramic honeycomb filter, extruded filter), our Ceramic Foam Filter have the advantages as below:

1. High thermal stability, stable chemical composition in high temperature,avoid the chemical reaction with the filtered molten metal.

2. High mechanical strength, large specific surface,efficient in purifying the metal flow.

3. Lower the filtering head loss,easy-operating,save energy. Smooth the metal flow,avoid the spray, spatter and backset,improve the exterior quality of the casting product,prevent the pore disfigurement,reduce the inferior rate.

4. Various size, shape and aperture,suitable for kinds of casting technique.

The Ceramic Foam Filter are widely used in non-ferrous metal smelt, Foundry Industrial of Copper, Aluminum Alloy, Cast Iron, Cast Steel and high temperature fume separator, special filling. silicon carbide ceramic foam filter been used to filter molten iron and copper liquid in the iron casting industry, improve the casting product quality highly.

- Q: What are the poor filtration effects of vacuum disc filters?

- The spindle speed is slow, the formation time of growth in the area of vacuum filter cake, production capacity increased gradually, but because the unit time of grout thickness and spindle speed slow is proportional to, so the ceramic filter capacity in a range of showing the highest.On the other hand, as the spindle speed slows down, the thickness of the slurry is thickened, and the moisture of the concentrate is also affected. For viscous material, ceramic filter with ceramic plate to work as filter media, when the cake is formed gradually into the porous filter medium filter cake itself, and the cake is not easy to form a viscous material, forming a dry cake appearance does not slow, the spindle speed is easy to reduce the water content of concentrate. Similarly, the spindle speed is accelerated, the cake formation time in the vacuum zone is shortened, and the slurry thickness is reduced, and the material can be improved for the easy molding material. But the spindle speed is too fast to be cleaned after each cycle of the ceramic plate. As for the viscous material, the cake is difficult to form after the spindle speed increases, and it will affect the capacity. Therefore, the use of ceramic filter should focus on the inherent nature of the concentrate to explore the best spindle speed.

- Q: How many degrees does the ceramic filter melt?

- Alumina made from tabular corundum can be used over 1800 degrees!SiC if there is atmosphere, protection will be higher, there is no atmosphere protection, because the existence of oxidation, generally not more than 1600.Corundum, mullite, 1750 degrees small meaning.

- Q: What happens when the pressure on the filter plate is uneven during backwashing?

- It should be said that the ceramic filter backwash, usually with a certain pressure of clean water to backwash.

- Q: What's the reason for high water content in filtration copper concentrate?

- Ceramic filter plate1) the service life of the ceramic filter plate has arrived.2), ceramic filter plate uneven in quality on the market, the production capacity of some ceramic products difference (table mask size is too large or pore size uniformity is poor as a result of suction effect is poor, short life), but the price is low, but some users in order to reduce the operation cost of ceramic machine, tend to choose low price the ceramic plate, sometimes a ceramic machine ceramic filter plate with several may be different, so do not get the expected effect in normal use.In addition, the concentrator slurry, especially metal slurry, is very powerful on the wear of ceramic filter plate, the mechanical strength and wear resistance of ceramic filter plate requirements (corundum has high mechanical strength, good abrasion resistance, especially suitable for metal slurry dehydration).When selecting ceramic filter boards, these two points should be taken as a reference.

- Q: What is the working pressure of the ceramic filter?

- Vacuum pressure or suction is the vacuum of the equipment, the size of the vacuum directly affects the effect of ceramic filter board suction (yield and water content). The vacuum system of ceramic filter consists of vacuum pumps, tanks, distribution device, ceramic filter plate and a connecting pipe is composed of ceramic filter, the vacuum pump is generally 2BV series water circulation pump, the vacuum pump vacuum limit is -0.097MPa, using a vacuum pump for a long time or vacuum system has poor sealing performance may cause a certain degree of vacuum distortion, so the ceramic filter vacuum is generally difficult to achieve in the -0.097MPa, -0.08 ~ 0.097MPa, which indicates that the vacuum degree is good, such as the vacuum degree is not up to -0.07MPa or less, the vacuum system may be an exception.

- Q: Microporous ceramic filter plate cleaning

- Ceramic filter comes with a combined cleaning system, usually to ensure backwashing normal, combined cleaning (nitric acid + ultrasonic + backwash) in place.

- Q: Ceramic filter capacity.

- You ask too general, to say processing capacity (ie capacity), at least to provide material conditions, such as: material name, concentration, particle size distribution. In addition, the basic conditions of equipment operation should be taken into account.

- Q: Ceramic filter cleaning, sulfuric acid cleaning

- Ceramic filter medium is ceramic, ceramic generally resistant to strong acid, alkali, cleaning, it is best to use nitric acid, hydrochloric acid next, not recommended to use sulfuric acid.

- Q: Excuse me, what's the reason that all ceramic filters do not attract ore?

- Vacuum system failure, no vacuum or vacuum can not meet the requirements. Should check the vacuum pump and vacuum piping, distribution head, ceramic plate, such as failure or leakage.

- Q: What is the backwashing pressure of the ceramic filter?

- The working process of ceramic filter is: suction - drying - unloading - backwash - suction - drying - unloading - backwash...... In circulation, suction, the drying process is to make the slurry liquid by vacuum suction and capillary effect (usually water) through the filter media from the left, the filter cake on the filter medium (the two processes like syringe pumping), and then through the scraper discharge, after unloading, ceramic filter machine is complete a cycle in the absorption slurry, drying process, some fine particles may enter the filter medium or stacked on the surface (a lot of pipeline internal filtration medium ceramic filter plate), these small particles blockage will make the filter medium permeability and filtering effect of the loss from the poor, in order to reduce the possibility of blockage ceramic filter, will enter the backwash (this process is like a water jet injector). Ceramic filter backwash is through the pressure of water, these small particles plug discharge ceramic filter board.

Send your message to us

SIC Ceramic Filter Plate for Foundry Filtration

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords