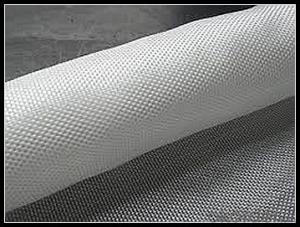

Géotextile 200 G/M2 Short Civil Woven Geotextiles Fabric for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geotextiles, Nonwoven Geotextile woven Geotextile

Width:

1m-8m

Length:

Customer Requirment

Weight:

100g/m2-1500g/m2

Color:

White, Black, etc

WOVEN GEOTEXTILES

1 High Performance

2 High Tensile Modulus

3 Monofilament

4 lit Film

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles help with soil confinement in erosion control tubes?

- Geotextiles help with soil confinement in erosion control tubes by acting as a barrier that holds the soil in place, preventing erosion. They provide stability and reinforcement to the soil, reducing the risk of displacement and erosion caused by water flow. Additionally, geotextiles allow water to pass through while retaining the soil particles, promoting proper drainage and preventing clogging within the erosion control tubes.

- Q: Can geotextiles be used in rockfall protection works?

- Yes, geotextiles can be used in rockfall protection works. Geotextiles are often used as a form of erosion control and soil stabilization, and they can also be effective in mitigating rockfall hazards. By installing geotextiles on slopes or embankments, they can help to absorb the impact of falling rocks, prevent the rocks from gaining momentum, and reduce the risk of damage or injury caused by rockfall.

- Q: How do geotextiles help with reinforcement of geogrid wall systems?

- Geotextiles help with the reinforcement of geogrid wall systems by providing additional strength and stability to the structure. They act as a separator between the soil layers and the geogrid, preventing soil migration and maintaining the integrity of the wall system. Geotextiles also distribute loads evenly across the geogrid, reducing the risk of localized failures and improving overall performance and durability of the reinforced wall.

- Q: Now geotextile price quota how?

- 2017 geotextile price cheaper than last year, the current price of raw materials is relatively stable production. Geotextile classification of many, you ask more general, so no way to give you a detailed offer. Different technical requirements are uneven prices, but the overall price has come down, and is now the lowest price since 2017.

- Q: How do geotextiles aid in the reduction of soil settlement?

- Geotextiles aid in the reduction of soil settlement by providing a separation layer between two soil layers, preventing intermixing and consolidation. This separation minimizes the migration of fine particles and water, maintaining the stability and integrity of the soil layers, ultimately reducing settlement.

- Q: High-speed rail 2-type sliding layer to use two cloth a film, geotextile wool surface close to the concrete, but in the geotextile between the smooth and matte surface there is controversy, both sides of the geotextile is fluffy soft , A smooth side of some hard, hope to understand the master to answer the hairy side is smooth or matte surface? Thank you more

- Hairy side is smooth, do when the hair surface paste concrete, on the film and then meet the smooth surface, that is, both sides of the hairy folder to the middle of the structure, or not play the role of sliding

- Q: What are the different geotextile weight classes and their applications?

- Geotextiles are categorized into different weight classes based on their mass per unit area. These weight classes range from lightweight to heavyweight. Lightweight geotextiles, usually less than 200 grams per square meter (gsm), are commonly used in erosion control applications, such as slope stabilization and vegetation support. They provide filtration and separation functions while allowing water to pass through. Medium-weight geotextiles, typically ranging from 200 to 400 gsm, are often employed in applications like road stabilization, embankment reinforcement, and subgrade separation. They offer a balance between strength and permeability, ensuring proper drainage and preventing soil movement. Heavyweight geotextiles, exceeding 400 gsm, are primarily used in applications requiring high strength and durability. These include shoreline protection, coastal engineering, and land reclamation projects. They provide robust reinforcement and act as a barrier against erosion and wave action. The choice of geotextile weight class depends on the specific engineering requirements of the project, such as soil conditions, anticipated loads, and desired drainage characteristics.

- Q: What are the applications of geotextiles?

- Geotextiles have a wide range of applications in civil engineering and environmental projects. They are commonly used in road construction, where they provide stability, erosion control, and reinforcement. Geotextiles are also utilized in landfills to separate and protect soil layers, preventing contamination. Additionally, they are employed in coastal engineering to mitigate erosion and stabilize shorelines. Geotextiles are also used in drainage systems, agriculture, and landscaping to control erosion, filter water, and promote vegetation growth.

- Q: Mainly how to filter layer construction, cutting for the weak weathering rock

- The walls behind the sandbags ah, but in most cases are mechanical backfill, and then the top surface of a layer of sandbags and composite drainage network mean

- Q: How do geotextiles contribute to the cost-effectiveness of construction projects?

- Geotextiles contribute to the cost-effectiveness of construction projects by providing various benefits. They act as a barrier against soil erosion, reducing the need for expensive erosion control measures. Geotextiles also enhance soil stability, allowing for the use of less expensive and readily available fill materials. Additionally, they improve drainage and filtration, minimizing the need for costly drainage systems. Overall, geotextiles help optimize construction processes, reduce material and labor costs, and extend the lifespan of structures, making them a cost-effective choice for construction projects.

Send your message to us

Géotextile 200 G/M2 Short Civil Woven Geotextiles Fabric for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords