Several Sizes FRP Fiber Reinforced Plastic Pipe flexible making machine of New Design

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 25 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

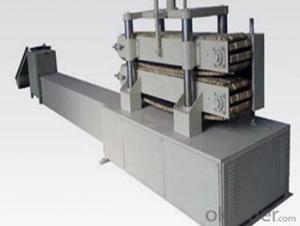

Several Sizes FRP Fiber Reinforced Plastic Pipe flexible making machine of New Design

Product Description:

1.PVC fiber reinforced pipe production line has a good market in worldwide. We can supply PVC fiber reinforced hose production line with competitive price and high quality.

2.PVC fiber reinforced pipe can be used as pipelines to conveying air, water, gas, oil and other kind of fluid and gas.

Product Features:

1)Used composite material to winding pipe for energy transport, industrial water and irrigation system2)The machine high automatic control,

3)Production speed high, raw material utilization high and cost low,

4)Good working condition and stable performance,

5)Stable pipe quality and easy connection of sleeve coupler.

Product Parameter:

Name | Several Sizes FRP Fiber Reinforced Plastic Pipe flexible making machine of New Design |

Brand | CMAX |

Weight | 5-10TON |

Dimension(L*W*H) | 21m*1.2m*2.5m |

Power | 30kw |

Voltage | 380V 50HZ |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Pipe |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Hebei, China (Mainland) |

Color | Customizable |

Warranty | 1 Year |

Time of Delivery | 30-45 days |

Product Pictures:

Our Services:

1. Warranty period: 1 year

2. Spare parts: Non-artificial damage parts, during warranty period, can be provided free of charge

3. Testing and debugging: Every machine will be tested and debugged before shipment

4. Training and maintaining: Sending our engineer to your factory or sending your machine operator to our factory

FAQ:

1.How can you ensure your quality?

First, welcome to visit us. After your vision in our company , envionment and work team, you can judge by yourself.

Second, according to your request, we can provide the same sample for you to confirm.

Third, We have inspectional department.

2. What's kind of payment you can accept?

We can accept L/C at sight, and T/T payment and so on.

3. Can we visit your company?

Welcome. We hope you and your team come to our company.

4.Can you provide sample ?

Yes, we can provide sample and it's free. You only charge the freight fee, and we will return the freight fee if you set the order.

- Q: What kind of equipment does the plastic bottle crush processing plant need?

- Plastic bottle initial processing, with crusher or broken cleaning machine, sheet cleaning machine, dryer

- Q: Plastic blank in the gear hobbing machine processing, hob and workpiece is not to heat, then plastic is not easy to stick on the machine body.Just want to know the plastic gear processing technology is how, and ordinary steel gear processing technology difference where?.The more detailed, the better. Thank you

- This problem, we have the right to speak, first of all, the plastic material relative to steel are quite soft, so the heating problem, processing on hobbing machine, the heat can be ignored, and, in the gear processing machine will have cooling facilities, to cool the workpiece. So this question, Louzhu worry too much.Also, plastic gears, casting molding, but also useful blank after cutting and forming, and this steel and gear is no big process difference......

- Q: The manufacturing process of plastic products? Who knows?

- 1. the manufacturing process of plastic products, that is, the processing of plastic bottles, refers to the process of making the final plastic products from polymers made from synthetic resin manufacturing plants. 2., processing methods (and plastic processing), including: plastic (Molding), extrusion (extrusion), injection molding (injection molding), blow molding (hollow forming), rolling and so on. Detailed manufacturing process flow:(1) press molding: molding or pressing forming. Plastic molding is mainly used for molding phenolic resins, urea formaldehyde resins, unsaturated polyester resins and other thermosetting plastics.(2): extrusion, extrusion molding, extrusion machine is used (extruder) will be heated by continuous resin mold, extrusion method of desired shape. The extrusion molding sometimes have to thermosetting plastic, and can be used for foam molding. The advantage of extrusion is that it can extrude various shapes of products. The production efficiency is high, it can be automated and continuous production. The disadvantage is that thermosetting plastics can not be widely used in this process, and the size of products is prone to deviation. (3) injection molding: injection molding. Injection molding is an injection molding machine (or injection machine) that uses thermoplastic melts to be injected into the mold at high pressure to cool and solidify the product. Injection molding can also be used for the formation of thermosetting plastics and foams. Injection molding has the advantages of high production speed, high efficiency, automation in operation, and the ability to form complex parts. It is especially suitable for mass production. The disadvantage is the high cost of equipment and moulds, and the difficulty of cleaning of injection molding machines.

- Q: Plastic machinery plastic pellet production process _ particles recycled plastics particles

- 16 、 domestic garbage plastic particle flotation device17 、 granular plastics dehumidification drying system18. Methods for the preparation of colored plastics or colored polymeric particles19. A method for producing a particulate formulation that is soluble in a plastic stain20. The spherical particles are prepared by the plastic melt21. Lactam based pigments and their use in the production of colored plastics or polymeric colored particles22. Methods for producing colored plastics or polymeric colored particles23, columnar particles of plastic compound additive, production process and application thereof24, manufacturing method of waste plastic particles and thermal decomposition method thereof25. The preparation of colored plastic or polymer dye granules26. Azo dyes, their preparation methods and their applications in the manufacture of colored plastics or polymers, colouring particles, and dyeing or printing of hydrophobic fiber materials27, pyridine ketone dye, process for the preparation thereof, and use in the manufacture of colored plastic or polymer colored particles28, pyridine ketone dye, process for the preparation thereof, and use thereof in the preparation of colored plastics or polymeric colorant particles29. Coating compositions of thermoplastic resin particles for forming foam containers30. Adsorption dryer for plastic material particles

- Q: now have no market quite suck me how to go find the market ask predecessors and friends hope that they can point out a way to thank you

- Hello, where are you? We can talk about it. I do domestic trade,

- Q: I haven't done it before, and I don't know how to do it Would you please tell me how to do this? How to do it? Good to do

- Good to do, there is money, what is good to do, grasp the source of raw materials ah, finished marketing ah!

- Q: How much is the investment? TenCan be processed daily plastic bags, woven bags, garbage bags, clothes bags, there are printed words like that.There is a 300 square foot factory empty home now, best can step can do this ~ ~ wherever he goes high profits? Just try to compare and see what is worth investing in! Trouble you expert pointing! Thanks.

- A production line (including the host, auxiliary equipment etc.) is about 25 or so long, the width of a few meters to tens of meters, according to your product, choice of the business, we must find what training are in place, the installation and debugging and give training of workers

- Q: Why is the dimensional accuracy of molded plastic parts much lower than the accuracy of machined products?

- Therefore, the precision of plastic products is lower than that of machined products by 1~2 grades.

- Q: How is the processing cost of plastic parts calculated? Would you please tell me how to calculate the processing cost of plastic parts? For example, how is the processing fee formed?

- Cost of raw materials, labor costs, mechanical fees, tax increases, plus other

- Q: ABS plastic processing flow

- ABS resin is a three element copolymer developed on the basis of modification of polystyrene resin. A stands for acrylonitrile, B for butadiene, and S for styrene. ABS resin has three components, the comprehensive performance of A can improve the oil resistance, chemical corrosion resistance, which has a certain surface hardness; B ABS showed a rubbery toughness, improve impact toughness; S ABS plastics showed good fluidity, which has a good performance of thermoplastic plastic molding processing. ABS plastic is mainly used in the manufacture of instruments, instruments, household appliances, telephones, TV sets and so on. ABS plastic is used to make metal luster, and ABS is used instead of metal. Our factory produces various types of refrigerator liner and all kinds of plastic products, ABS injection products accounted for more than 88% of the total refrigerator plastic products

Send your message to us

Several Sizes FRP Fiber Reinforced Plastic Pipe flexible making machine of New Design

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 25 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches