Selling a variety of welded steel pipe API and ASTM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of ERW Welded Steel Pipe:

ERW Welded Steel Pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of ERW Welded Steel Pipe:

• High manufacturing accuracy

• Higher strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• More reasonable price

3、ERW Welded Steel Pipe Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | Q235 Q345 X42 X52 X65 |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of ERW Welded Steel Pipe:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we have professional engineering and technology team, and we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

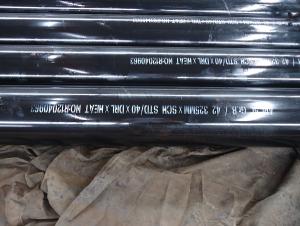

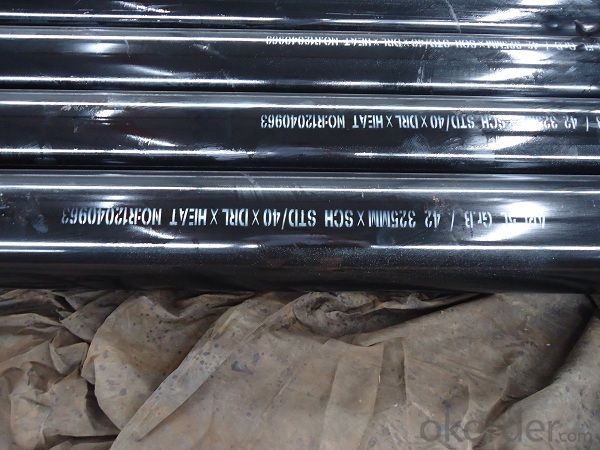

6、ERW Welded Steel Pipe Images:

- Q: Are steel pipes suitable for use in coastal areas?

- Yes, steel pipes are suitable for use in coastal areas. Steel is highly durable and resistant to corrosion, making it an ideal choice for withstanding the harsh conditions typically found in coastal environments, such as saltwater, high humidity, and strong winds. Additionally, steel pipes offer excellent strength and stability, ensuring their longevity and reliability in coastal applications.

- Q: How are steel pipes used in the manufacturing of oil refineries?

- Steel pipes are essential in the manufacturing of oil refineries as they are used for various purposes such as transporting crude oil, petroleum products, and other fluids throughout the facility. These pipes are used for the construction of pipelines, storage tanks, and various process equipment within the refinery. They provide a reliable and durable means of conveying and distributing fluids necessary for the refining process, ensuring efficient operations and the safe transportation of oil and its byproducts.

- Q: Are steel pipes more expensive than other types of pipes?

- The cost of steel pipes can vary compared to other pipe types due to various factors. In terms of upfront cost, steel pipes are generally more expensive than certain pipe types. This is primarily because the production process and raw materials for steel pipes are highly costly. Additionally, steel pipes are renowned for their strength and durability, making them a popular option for applications involving high pressure or extreme conditions. However, when considering long-term costs and benefits, steel pipes are often more economically viable. They have a longer lifespan compared to certain pipes, reducing the need for frequent repairs or replacements. Furthermore, steel pipes possess excellent corrosion resistance, making them suitable for diverse environments and reducing maintenance expenses over time. Moreover, the strength and durability of steel pipes contribute to a reduced likelihood of leaks or failures, resulting in significant cost savings to prevent damage or loss. When comparing the cost of steel pipes to other pipe types, it is crucial to consider the specific requirements and characteristics of the project or application. Factors like the transported fluid or material, required pressure rating, expected lifespan, and environmental conditions should all be taken into account. Ultimately, despite steel pipes having a higher upfront cost, their long-term durability and reliability often make them a cost-effective choice in numerous applications.

- Q: What is the difference between steel pipe and HDPE pipe?

- Steel pipe and HDPE pipe have different compositions and characteristics, making them suitable for various applications. Steel pipe, made of steel, is a robust and durable material commonly used in industrial and infrastructure projects that require strength and reliability. It can withstand high pressure, temperature, and heavy loads, and is resistant to corrosion for both above-ground and underground installations. On the other hand, HDPE pipe is composed of high-density polyethylene, a plastic polymer. These pipes are lightweight, flexible, and easy to install, making them ideal for water supply, drainage systems, and agricultural irrigation. They are resistant to chemicals, abrasion, and UV rays, making them suitable for indoor and outdoor use. HDPE pipes also have a long service life and require low maintenance. In terms of cost, steel pipes are generally more expensive due to the raw materials and manufacturing process involved. However, they are chosen for their superior strength and durability in applications with high pressure or extreme conditions. HDPE pipes offer a cost-effective solution for applications that don't require the same level of strength and durability. In summary, the differences between steel pipe and HDPE pipe lie in their composition, strength, durability, and cost. Steel pipe is known for its strength and reliability, while HDPE pipe offers flexibility, easy installation, and resistance to chemicals and UV rays. The choice between the two depends on the specific application and project requirements.

- Q: What are the common standards and specifications for steel pipes?

- The common standards and specifications for steel pipes include ASTM A53, ASTM A106, API 5L, and ISO 3183. These standards outline the requirements for the manufacturing, dimensions, and mechanical properties of steel pipes used in various industries such as oil and gas, construction, and transportation. Additionally, specific applications may have their own standards and specifications that need to be met for quality and safety purposes.

- Q: How do you calculate the pipe pressure loss coefficient for steel pipes?

- To calculate the pipe pressure loss coefficient for steel pipes, you can use the Darcy-Weisbach equation, which is a widely accepted method for determining the pressure loss in pipes due to friction. The equation is as follows: ΔP = f × (L/D) × (V^2/2g) Where: - ΔP is the pressure loss (in units of pressure, such as psi or Pa) - f is the Darcy friction factor (dimensionless) - L is the length of the pipe (in units of length, such as feet or meters) - D is the diameter of the pipe (in units of length, such as feet or meters) - V is the velocity of the fluid flowing through the pipe (in units of velocity, such as ft/s or m/s) - g is the acceleration due to gravity (in units of acceleration, such as ft/s² or m/s²) The Darcy friction factor (f) is a dimensionless parameter that represents the amount of frictional resistance in the pipe. For steel pipes, the friction factor can be determined using the Moody diagram, which is a graphical representation of the relationship between the Reynolds number (Re) and the friction factor (f) for different pipe roughness. To calculate the pressure loss coefficient, you need to find the value of the friction factor (f) based on the Reynolds number (Re) and the relative roughness of the steel pipe (ε/D). The Reynolds number is given by: Re = (ρ × V × D) / μ Where: - ρ is the density of the fluid (in units of mass per unit volume, such as lb/ft³ or kg/m³) - V is the velocity of the fluid (in units of velocity, such as ft/s or m/s) - D is the diameter of the pipe (in units of length, such as feet or meters) - μ is the dynamic viscosity of the fluid (in units of force per unit area per unit time, such as lb/ft·s or kg/m·s) Once you have the Reynolds number (Re) and the relative roughness (ε/D), you can use the Moody diagram to find the corresponding friction factor (f). The pressure loss coefficient (K) can then be calculated as: K = f × (L/D) Where: - L is the length of the pipe (in units of length, such as feet or meters) - D is the diameter of the pipe (in units of length, such as feet or meters) By using the Darcy-Weisbach equation and the Moody diagram, you can accurately calculate the pressure loss coefficient for steel pipes, which is essential for designing and analyzing fluid flow systems.

- Q: Can steel pipes be used for fire protection systems?

- Yes, steel pipes can be used for fire protection systems. Steel pipes are commonly used in fire sprinkler systems because they have high strength and durability, making them suitable for carrying pressurized water to extinguish fires. Steel pipes also have fire-resistant properties, which further enhances their suitability for fire protection systems.

- Q: What is the role of steel pipes in the transportation of petroleum products?

- Steel pipes play a crucial role in the transportation of petroleum products as they provide a safe and efficient means of transferring oil and gas over long distances. These pipes are strong, durable, and resistant to corrosion, ensuring the integrity of the pipelines and preventing leakage or contamination of the products. Additionally, steel pipes have high heat resistance, making them suitable for transporting hot petroleum products. Overall, steel pipes serve as the backbone of the petroleum transportation infrastructure, facilitating the smooth and reliable delivery of these essential energy resources.

- Q: What are the future trends in steel pipe manufacturing?

- Some future trends in steel pipe manufacturing include the adoption of advanced technologies such as automation and robotics, the development of high-performance and sustainable materials, the implementation of efficient and eco-friendly production processes, and the integration of digitalization and data analytics for improved quality control and supply chain management. Additionally, there is a growing focus on the development of specialized pipes for specific industries such as oil and gas, construction, and automotive, as well as an increased emphasis on product customization and tailored solutions to meet the evolving needs of customers.

- Q: How are steel pipes repaired if they develop leaks?

- Steel pipes can be repaired if they develop leaks through various methods such as welding, clamping, or using epoxy compounds. The specific repair technique depends on the size and location of the leak as well as the type of pipe, and it is typically carried out by trained professionals with the necessary equipment and expertise.

Send your message to us

Selling a variety of welded steel pipe API and ASTM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords