Seamless Steel pipe High Quality , Best Price and hot selling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Seamless Steel pipe High Quality , Best Price and hot selling:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of Seamless Steel pipe High Quality , Best Price and hot selling:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Seamless Steel pipe High Quality , Best Price and hot selling Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Steel pipe High Quality , Best Price and hot selling:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

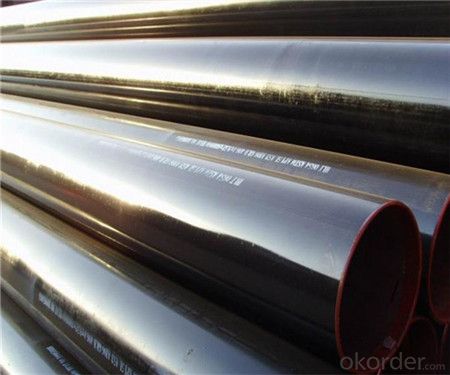

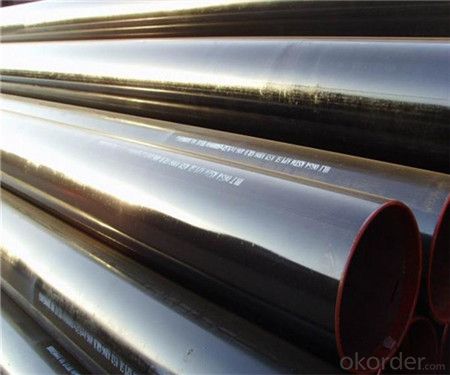

6、Seamless Steel pipe High Quality , Best Price and hot selling Images:

- Q: Who knows what is the difference between double submerged arc welded pipe and longitudinal submerged arc welding?

- The straight seam welding is relative to the spiral welding and the T-shaped welding, and so on.

- Q: Can steel pipes be used for scaffolding?

- Yes, steel pipes can be used for scaffolding. Steel pipes are commonly used in scaffolding due to their strength, durability, and ability to support heavy loads. They provide a stable and secure structure for workers to access elevated areas during construction or maintenance projects.

- Q: What are the different types of steel pipe tees?

- There are several different types of steel pipe tees that are commonly used in various plumbing and piping applications. 1. Equal tee: This type of tee has all three branches of the same size, resulting in equal flow of fluid or gas through each branch. 2. Unequal tee: As the name suggests, an unequal tee has branches of different sizes. This allows for the merging or diversion of flows with different volumes or pressures. 3. Reducing tee: This type of tee is used when the branch size is smaller than the main pipe size. It allows for a reduction in size while maintaining the flow in the main line. 4. Barred tee: A barred tee is used in situations where a pig (a device used for cleaning and inspecting pipelines) needs to be inserted or removed from the line. It has a bar welded across one or two of the branches to create a bypass for the pig. 5. Lateral tee: A lateral tee has a 45-degree or 90-degree branch angle, allowing for the branch line to run perpendicular to the main line. It is commonly used in fire sprinkler systems or in situations where a change in direction is required. 6. Compression tee: This type of tee is used in gas or hydraulic systems, where the branches are connected using compression fittings instead of welding or threading. 7. Butt-weld tee: A butt-weld tee is used in high-pressure and high-temperature applications. It is welded to the main pipe using butt-welding techniques, ensuring a strong and leak-proof connection. These are some of the most common types of steel pipe tees used in various industries. The selection of the appropriate tee depends on the specific requirements of the project, including the size of the pipes, the flow rates, and the materials being transported.

- Q: Can steel pipes be used for conveying natural gas?

- Yes, steel pipes can be used for conveying natural gas. In fact, steel pipes are commonly used for this purpose due to their strength, durability, and ability to withstand high pressures. Steel pipes also have excellent resistance to corrosion, which is crucial when transporting natural gas that contains impurities like water and sulfur compounds. Additionally, steel pipes can be easily welded, making them ideal for connecting different sections of the pipeline. Overall, steel pipes are a reliable and safe choice for conveying natural gas.

- Q: What is the difference between internal lining and external coating of steel pipes?

- The difference between internal lining and external coating of steel pipes lies in their respective purposes and locations. Internal lining refers to the material applied inside the steel pipes to protect the inner surface from corrosion, abrasion, or other forms of damage. It acts as a barrier between the transported fluids or substances and the steel pipe, preventing them from coming into direct contact and causing deterioration. The internal lining is typically made of materials like epoxy, polyethylene, or cement mortar, depending on the specific requirements and the nature of the transported substances. It ensures the longevity and integrity of the steel pipe by reducing the chances of internal corrosion and minimizing the risk of contamination. External coating, on the other hand, is applied to the outer surface of the steel pipes. Its main purpose is to provide protection against external factors such as weathering, soil corrosion, and mechanical damage. The external coating acts as a shield, safeguarding the steel pipe from environmental conditions like moisture, UV radiation, chemicals, and physical impact. Common materials used for external coatings include fusion-bonded epoxy, polyethylene, polypropylene, or bitumen. The choice of coating depends on factors like the exposure conditions, temperature, and the type of soil or surroundings the steel pipe will encounter. In summary, while internal lining protects the inner surface of steel pipes from corrosion and damage caused by transported substances, external coating acts as a barrier against external elements and physical stresses. Both internal lining and external coating play vital roles in ensuring the durability and reliability of steel pipes in various applications, such as oil and gas pipelines, water supply systems, or industrial processes.

- Q: Hot galvanized steel pipe for use?

- Hot galvanized pipe: in order to improve the corrosion resistance of steel pipe, galvanized steel pipe. Galvanized steel pipe hot galvanized and galvanized two kinds, hot galvanized, zinc coating thickness, zinc plating cost is low, the surface is not very smooth.The hot-dip galvanized pipe is an alloy layer that causes molten metal to react with the iron matrix, thus combining the substrate with the two coating. Hot dip galvanizing is the first steel pickling, in order to remove iron, steel pipe surface after pickling, cleaning by ammonium chloride or zinc chloride solution or ammonium chloride and zinc chloride aqueous solution tank, and then into the hot dip tank. Hot galvanizing has the advantages of uniform coating, strong adhesion, long service life and so on. A complex physical and chemical reaction is formed between the steel tube matrix and the molten plating solution to form a corrosion resistant structure with a tight zinc - iron alloy layer. The alloy layer is integrated with the pure zinc layer and the steel pipe matrix. Therefore, it has strong corrosion resistance.

- Q: What is the difference between hot-finished and cold-finished steel pipes?

- Distinguishing hot-finished and cold-finished steel pipes can be done by examining their manufacturing processes, which lead to different characteristics and applications. To create hot-finished steel pipes, a solid steel billet is heated to a high temperature and then pierced to form a hollow tube. This process, known as hot rolling, ensures that the steel is easily shaped and malleable. As a result, hot-finished steel pipes have rough surfaces and rounded edges. They are generally larger in diameter and have thicker walls. These pipes are commonly utilized in industries that demand high strength and pressure resistance, like the oil and gas sector, structural projects, and heavy machinery manufacturing. On the other hand, cold-finished steel pipes are produced using a process called cold drawing. This involves pulling the hot-finished steel pipe through a die at room temperature to reduce its diameter and achieve the desired shape. The cold drawing process yields a more precise and smoother finish for the steel pipes. Cold-finished steel pipes possess smoother surfaces and sharper edges compared to their hot-finished counterparts. They are typically smaller in diameter and have thinner walls. Cold-finished steel pipes are commonly applied in industries that require accurate dimensions, such as automotive part manufacturing, construction component fabrication, and machinery production. In conclusion, the primary disparity between hot-finished and cold-finished steel pipes stems from their manufacturing processes, resulting in variations in surface finish, dimensions, and applications. Hot-finished pipes are suitable for applications that demand high strength and pressure resistance, while cold-finished pipes are ideal for applications that require precise dimensions and smooth surfaces.

- Q: What is lined pipe?

- There are inner pipe jacket, such as day, tube, etc.; there are outside the pipe painted, such as large-diameter water pipes. An internally coated steel pipe for corrosive medium fluids replaces the expensive stainless steel pipe.

- Q: How do you measure the diameter of a steel pipe?

- To determine the diameter of a steel pipe, various methods can be employed based on the tools accessible and the required accuracy. Here are several commonly used techniques: 1. Utilizing calipers: The most precise approach involves employing a set of calipers. Expand the calipers to their maximum width and then gradually close them around the pipe until they fit snugly. The diameter of the pipe will be indicated by the measurement displayed on the calipers. 2. Tape measure or ruler: In the absence of calipers, a tape measure or ruler can be employed. Wrap the tape measure or ruler around the pipe's circumference, ensuring a snug fit without excessive tightness. Divide the measurement by pi (3.14) to obtain the diameter. Although this method may not offer the same accuracy as calipers, it can provide a rough estimate. 3. String or flexible tape: Another option is to employ a piece of string or flexible tape. Wrap it around the pipe's circumference and mark the point of overlap. Utilize a ruler or tape measure to determine the length of the marked section. Divide this measurement by pi (3.14) to ascertain the diameter. 4. Implementing a pipe gauge: A specialized tool known as a pipe gauge can be utilized for measuring pipe diameter. It comprises a series of circular holes accompanied by corresponding diameter labels. Simply insert the pipe into the hole that best matches its size, and the label will indicate the diameter. Bear in mind that it is crucial to measure the diameter at multiple points along the pipe to account for any irregularities or inconsistencies. For accurate measurements, it is advisable to take multiple readings and calculate the average diameter.

- Q: Are steel pipes suitable for underground irrigation systems?

- Underground irrigation systems can indeed benefit from the use of steel pipes. Renowned for their durability and strength, steel pipes exhibit resistance to corrosion and can withstand significant pressure. Furthermore, they are less prone to cracking or breaking when subjected to the weight and pressure of the ground. Moreover, steel pipes boast an extended lifespan, alleviating the need for frequent replacements. Nevertheless, it is crucial to consider the composition of the water being conveyed, as certain minerals or chemicals may induce corrosion over time. In such instances, it might be necessary to employ corrosion-resistant coatings or liners. All in all, steel pipes represent a dependable choice for underground irrigation systems, particularly in regions characterized by elevated water pressure or when durability takes precedence.

Send your message to us

Seamless Steel pipe High Quality , Best Price and hot selling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords