Rubber Hose for Sand and Grit Blasting Using Nano Technology

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 1000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rubber Hose for Sand and Grit Blasting

The kiynn brand rubber hose for sand and grit blasting is developed after 20 years of extensive studies. Using nano technology, the rubber hose exhibits characteristics of excellent wear-resistance, toughness as well as tolerance towards high pressure, with 3-5 folds wear-resistance of normal sand blast rubber hose and better performance.

Applications:

1. Useful in various kinds of sand and grit blasting machines.

2. In shipbuilding industry, it can be used for removing rust and enhancing adhesion before hull painting.

3. Other industries: Oil tank rust-removing and reinforcing; corrosion protection in gates of bridges and irrigation works; rustproof, de-oxidation, and paint removal for metallic parts.

Main structure:

Inner layer: Using natural rubber, polyurethane rubber and other composite rubbers as major materials, with the addition of special reinforcing agent.

Framework: The fabric reinforced sand blast rubber hose employs fine fabric (canvas) or chemical fabric cloth as reinforce layer; thus having good flexibility and loading-bearing capacity.

Outer layer: Using natural rubber and other composite rubbers, exhibiting good wear- and oxidation- resistance, long useful life and good view.

Main types:

Normal sand blasting rubber hose; rubber hose for waterway desilting, cementing pump truck, concrete, grout, sediment, coal injection truck, bulk cement truck, sandblast, big inch grout hose, white powder and dredging.

Blasting materials:

Quartz sand, steel shot, sediment, ball bearing, cement powder, cement concrete, dry powder mortar, coal fines, carbon powder, and mineral powder.

Suitable temperature: -40°C~+90°C

Technology standard: HG2192-2007

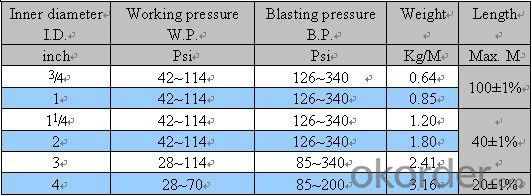

Technology parameters:

Note: 1.The weights above are all theoretical values, and the actual weight needs to be re-determined as the customer’s requirement.

2.Requirements for special working pressure, length, or colors may be satisfied according to orders

- Q: Can black soft rubber pipes be used as water pipes? Why is there a pungent odor?

- Black rubber hose is not suitable for water pipes, black rubber tube, or all the use of recycled rubber is very high; and black rubber tube is generally industrial use.

- Q: What does the letter of the high-pressure tubing connector mean?

- High pressure oil classification: high pressure wire braided hose, high pressure hose winding wire, large diameter, high pressure hose steel wire (fiber) reinforced nylon elastomer resin pipe, steel wire reinforced soft, high-pressure hose, hose, high temperature resistant polyurethane hose.Structure: high pressure oil pipe consists of steel wire winding skeleton layer and internal and external oil resistant rubber, corrosion resistant synthetic rubber and weather resistant special rubber.

- Q: Natural gas can be connected to a gas cooker. Can rubber tube be used?

- No, it's not safe. To purchase national standards products with 3C certification.

- Q: Rubber tube in the production process need to wrap cloth, in order to finalize the design, I want to know what cloth is winding cloth, what is the specification, please god!

- Polyamide (nylon) water cloth with high strength nylon filament as raw materials, the introduction of the Swiss high-speed shuttleless loom woven, has the characteristics of high density, fine texture, smooth surface, not deformation, surface sulfide even shrinkage, fracture strength, long service life, make good products and rubber skeleton material good adhesive effect the appearance of black, wove neat, shallow indentation.

- Q: Three yuan ethylene propylene rubber hose, hydraulic oil and oil?

- Finally, NBR (Ding Jing rubber), ACM (acrylate), FKM (FKM) can be non polar medium.

- Q: The rubber is sheathed on a metal cylinder. How should they be connected?

- If you describe it, it is recommended that a soft binder such as 704 silicone gel will be used to prevent shock absorption and separation. Metal surface to rust treatment, clean can be coated adhesive, rubber cover surface is best polished, degreasing treatment effect is good!

- Q: The function of rubber joint?

- The utility model has the advantages of small size, light weight, good elasticity, convenient installation and maintenance

- Q: How to distinguish the true and false corrosion resistant rubber soft joint?

- Method for distinguishing true and false corrosion resistant rubber soft joint:Put the rubber joint in the corrosive liquid which needs to pass. One day, 24h can see that the swelling ratio is not more than 5%!

- Q: How to replace natural gas hose? Steps?

- Rubber products are rotten, especially the kitchen fume gas hose to erosion, and temperature will cause the hose and hose aging, but also bear the pressure of gas altar, for safety, or in accordance with the gas company's proposal to replace a 2 year.

- Q: How long is the service life of a rubber tube?

- This is really bad to determine, the environmental impact is very large, so it is difficult to judge

Send your message to us

Rubber Hose for Sand and Grit Blasting Using Nano Technology

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 1000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords