Rock Wool Blanket and Board with Stable Quality Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rock Wool Board

Rockwool felt is produced from molten basalt rocks, spun to fine fibers, slightly bonded with binder formed into flexible rolls. It is also produced by stitching rock fibers with cotton or fiberglass yarns.It can be non-faced or faced with wire mesh.

Rockwool blanket uses high-quality basalt as raw material whose melting point is above 1000 ºC and has good effects on heat insulation and sound absorption.

It has good properties of fire resistance, pest proof, corrosion resistance, stable chemical property and do not contain asbestos. It is green environmental production and do no harm to human bodies

Product Applications:

It can be widely used as thermal insulation material for high-temperature pipe, tank, equipment and vessel in petroleum, chemical and metallurgy industry. It can also be applied to partition, ceiling and building wall as thermal insulation and sound absorption material in construction industry.

1,High compressive strength, tensile strength and good durability ensures the reliability and long-term stability of the product in the application.

2,Low thermal conductivity can effectively reduce the heat loss of the building to achieve energy saving and emission reduction.

3. Rock wool blanket will not release heat and poisonous smoke because of its incombustibility and can effectively partition the spread of flam when fire occurs.

4,It has good performance of non-hygroscopicity, ageing resistance and long-term stability.

5,It is light weight and easy to be cut and processed

Product Advantages:

1. Excellent thermal insulation

2. Fireproof

3. Good sound absorption property

4. Stable and durable.

5. High acidity coefficient

6. Good chemical stability and fiber durability.

Main Product Features:

Excellent performance

Fire-Proof

Good thermal Insulation

Soundproofing

Water-repellent

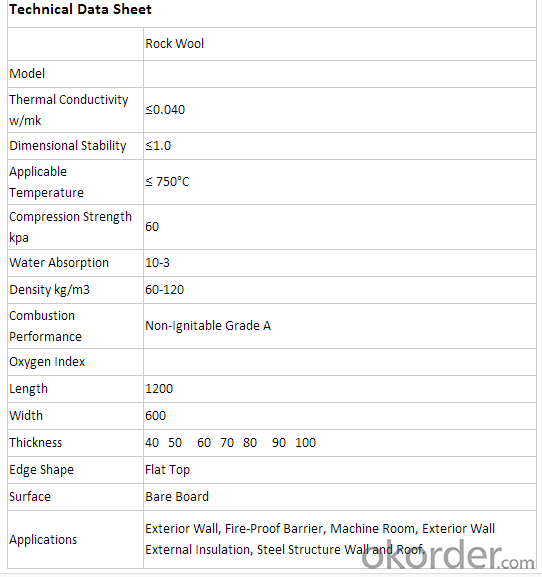

Product Specifications:

FAQ:

1.Q:What is your delivery time?

A : within 10-15 days after receive your prepayment,and we can also deliver as per your requirment.

2.Q:Which payment can you accept?

A: TT or LC.

3.Q:What is your MOQ?

A: 40'HQ container, that's about 65 cubic meters.

4.Q: I am interested in the products but I don't have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

5.Q: Can I get some samples for check?

A:Yes. Samples can be provided for free but you should take charge for the freight fee and we will deduct the cost from your first order.

Product Picture

- Q: What are the building energy saving materials?

- Glass wool is second kinds of products of mineral wool, with silica sand, limestone, fluorite and other minerals as the main raw material, by melting method and centrifugal method, using flame or high energy gas blowing process, the molten glass liquid made of inorganic fiber. Glass wool products have good thermal insulation, heat insulation, sound absorption, non burning, corrosion resistance and other properties. They are widely used in building, piping, storage tanks, boilers, aircraft, ships and other parts of the insulation, heat insulation and sound absorption.

- Q: What are the properties of fire-resistant coatings for steel structures?

- Ultra thin structure fire retardant coating refers to the coating thickness of 3mm (including 3 mm) less than, decorative effect is good, high temperature can expand foaming, fire-resistant limit is generally less than 2 H steel structure fire retardant coating. This kind of fire retardant coatings for steel structures is generally solvent system, bonding strength, weathering has good water resistance, good leveling, good decorative features such as superior; subjected to fire slow expansion foam fire insulation layer to form a dense solid, the fireproof layer has a strong impact resistance, the temperature rise of steel delay, effective protection of steel member. Ultra thin intumescent steel structure fire retardant coating can be sprayed, brushed or rolled. It is generally used in building steel structures with a fire resistance requirement of less than 2 h. At present, there has been a fire resistance to meet or exceed the new ultra-thin fireproof coating for steel structure of 2 varieties of H, it is mainly based on the special structure of the poly methyl acrylate or epoxy resin and amino resin, chlorinated paraffin, compound as base adhesive, with high degree of polymerization of ammonium polyphosphate, melamine and pentaerythritol, double as the fire retardant system, adding titanium dioxide, wollastonite and other inorganic refractory material, using 200# as solvent and solvent oil compound. At present, all kinds of light steel structure, grid and so on, use this type of fire retardant coatings for fire protection. Because this type of ultra-thin fireproof paint coating, making use of thick and thin fire retardant coating for steel structure is greatly reduced, thereby reducing the total cost of the project, the steel structure has been effective fire protection, is currently promoting varieties on the market.

- Q: What are the kinds of fire door core board?

- Inorganic fireproof insulating material, fire door core, such as rock wool, mineral wool, glass wool, aluminum silicate cotton, asbestos, expanded perlite, expanded vermiculite products, foam glass, microporous calcium silicate products. Inorganic materials are far better than organic materials and fire insulation performance and smokeless toxic performance, but there are some limitations, some non compressive degrees, must be attached to support carrier, carrier and brought fire and burning smoke toxicity problems, such as rock wool, mineral wool, glass wool, cotton, aluminium silicate asbestos is such; some high prices, the production of high energy consumption, such as foam glass, microporous calcium silicate in the case of such refractory; some itself is not high, moisture absorbent is large, such as cement or water glass based products, perlite cement or water glass based products, products such as vermiculite foam concrete is such, therefore restricted to varying degrees as the filling core material of the fire door.

- Q: What kinds of exterior wall thermal insulation materials are there in Northwest China?

- There are a lot of external insulation materials, including foam, mineral wool products, foam glass, expanded perlite insulation, powder particles insulation slurry EPS, spraying mineral cotton, foam cement insulation products, polystyrene particles, internal and external wall thermal insulation glazed hollow bead mortar and external wall putty and so on, you can according to the preferences and choose one or several price.

- Q: What is the heat preservation material?

- In accordance with applicable temperature range: can be divided into high temperature (700 degrees Celsius), medium temperature (1000~700 degrees Celsius) and low temperature (less than 100 degrees Celsius) three categories..According to different shapes are divided into: powder, granular, fibrous, block and other categories, but also divided into porous, mineral fiber and metal.According to different construction methods are divided into: wet wipe, filling type, lashing type, wrapped winding type, etc..

- Q: The difference between rock wool and mineral wool

- Cotton like short staple fibers made from silicate melts, including slag cotton, rock wool, glass wool and ceramic fibers, generally only refer to the first two.

- Q: What are the building thermal insulation materials in general?

- Qinglong hollow glass micro bead heat insulation technology is composed of hollow glass beads inorganic insulation mortar, impermeable crack mortar, alkali resistant fiberglass mesh cloth (or galvanized steel mesh) is composed of three parts, the core part is hollow bead mortar, thermal insulation mortar insulation for the past, empty valley clefts and low strength. Our company in recent years development and improvement, through the selection and adjustment of raw materials imported additives were modified to form a double micro structure inside the product, the material has the characteristics and functions of lightweight plastering mortar, excellent thermal insulation, heat insulation performance of the material is stable, excellent fireproof performance, convenient construction, is at present, the products of similar products.

- Q: What are the common thermal insulation materials?

- Mineral wool is the industrial waste slag as main raw materials by melting, cotton like insulation material made by injection method and centrifugal method: cotton is a natural rock as raw material is made of mineral wool. The commonly used rock such as Xuan Wuyan, diabase, amphibolite etc..Mineral wool characteristics: mineral cotton and products is a high-quality insulation materials, has more than 100 years of production and application history. The utility model has the advantages of light weight, heat preservation, heat insulation, sound absorption, good chemical stability, no burning and corrosion resistance, abundant raw material sources and low cost:

- Q: What is the difference between ordinary slag wool rock wool board and basalt rock wool board?

- Although rock wool and cotton products belong to CaO-Al2O3-SiO2 Portland slag system, but because of differences in their chemical composition on (Table 2), making them the phase composition of crystallization point falls in different regions in the CaO-Al2O3-SiO2 three phase diagram (Figure 1). From table 2 and figure 1 shows that the rock composition point (4, 5, 6 in the figure) are located on the 2 wollastonite gehetinite 2 calcium feldspar crystallization zone (CS-C2AS-CAS2 zone), the solid phase will have the three crystalline phase because of wollastonite, gehetinite, calcium do not have hard water feldspar characteristics, the water change is very small, the rock wool has good water resistance.

- Q: Fireproof rock wool board can be used as firewall?

- Composite rock wool board and slag wool board referred to as mineral wool, slag wool has been widely used in metallurgy, machinery, building materials, petroleum and chemical industry in 1970s, rock wool used for external wall thermal insulation in developed countries such as the EU has a history of nearly 30 years, but in our country because of its high cost and production cost, the economic costs of organic insulation the material is greater than, the application range is not big.

Send your message to us

Rock Wool Blanket and Board with Stable Quality Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches