Rock Wool Blanket and Board Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rock Wool Board

Rockwool felt is produced from molten basalt rocks, spun to fine fibers, slightly bonded with binder formed into flexible rolls. It is also produced by stitching rock fibers with cotton or fiberglass yarns.It can be non-faced or faced with wire mesh.

Rockwool blanket uses high-quality basalt as raw material whose melting point is above 1000 ºC and has good effects on heat insulation and sound absorption.

It has good properties of fire resistance, pest proof, corrosion resistance, stable chemical property and do not contain asbestos. It is green environmental production and do no harm to human bodies

Product Applications:

It can be widely used as thermal insulation material for high-temperature pipe, tank, equipment and vessel in petroleum, chemical and metallurgy industry. It can also be applied to partition, ceiling and building wall as thermal insulation and sound absorption material in construction industry.

1,High compressive strength, tensile strength and good durability ensures the reliability and long-term stability of the product in the application.

2,Low thermal conductivity can effectively reduce the heat loss of the building to achieve energy saving and emission reduction.

3. Rock wool blanket will not release heat and poisonous smoke because of its incombustibility and can effectively partition the spread of flam when fire occurs.

4,It has good performance of non-hygroscopicity, ageing resistance and long-term stability.

5,It is light weight and easy to be cut and processed

Product Advantages:

1. Excellent thermal insulation

2. Fireproof

3. Good sound absorption property

4. Stable and durable.

5. High acidity coefficient

6. Good chemical stability and fiber durability.

Main Product Features:

Excellent performance

Fire-Proof

Good thermal Insulation

Soundproofing

Water-repellent

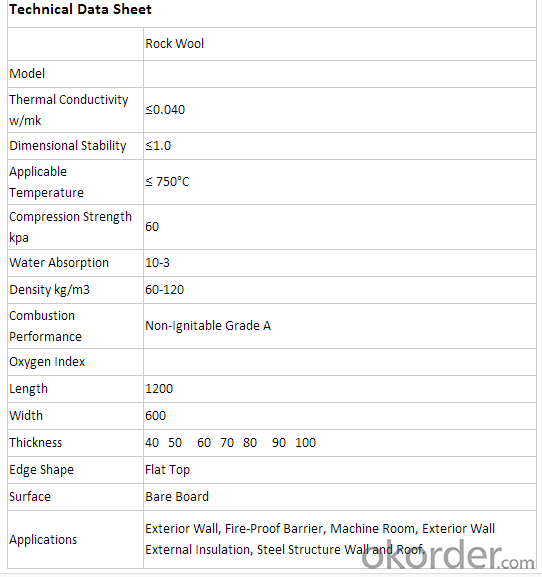

Product Specifications:

FAQ:

1.Q:What is your delivery time?

A : within 10-15 days after receive your prepayment,and we can also deliver as per your requirment.

2.Q:Which payment can you accept?

A: TT or LC.

3.Q:What is your MOQ?

A: 40'HQ container, that's about 65 cubic meters.

4.Q: I am interested in the products but I don't have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

5.Q: Can I get some samples for check?

A:Yes. Samples can be provided for free but you should take charge for the freight fee and we will deduct the cost from your first order.

Product Picture

- Q: What are the building energy saving materials?

- At present, China's common energy-saving insulation materials are mainly rock wool, glass wool, polystyrene foam, cement, polystyrene board, silicate composite insulation mortar.

- Q: What are the properties of fire-resistant coatings for steel structures?

- Thick steel structure fire retardant coating refers to the steel structure fireproof coating with coating thickness greater than 7 mm, less than or equal to 50 mm, granular surface, little density, low thermal conductivity, and refractory limit of 2 h or more. Because of the thick fire retardant coating composition for inorganic materials, so the fire performance is stable, long-term effect is good, but the coating components of larger particles, the coating appearance is not smooth, affect the overall appearance of the building, so most structure for concealed works. In the fire, the material has a granular surface, a smaller density, a low thermal conductivity, or a heat absorbing property in the coating, delaying the temperature rise of the steel and protecting the steel. This kind of fire retardant coating is suitable for inorganic binder (such as water glass, silica sol, aluminum phosphate salt, refractory cement, etc.) together with inorganic light insulation aggregate materials (such as perlite, vermiculite, bouldering, sea and fly ash cenosphere), fire retardant additives, chemicals and materials (enhanced such as rock wool, aluminum silicate fiber, ceramic fiber, glass fiber and filler) mixed together, has the advantages of low cost. Spraying is often used in construction. It is suitable for indoor and outdoor concealed steel structure, high-rise steel structure and multi story steel structure with requirements of fire resistance above 2 h. Such as: high-rise building columns, general industrial and civil buildings in support of multi-storey columns of fire resistance should reach 3 h, the need to use this thick fire-retardant coating protection.

- Q: What is the heat preservation material?

- Thermal insulation materials are generally used to guide heat coefficient less than or equal to 0.2 of the material. Thermal insulation material development is very fast, and in industry and building the use of good insulation technology and materials, often can get twice the result with half the effort. Each ton of mineral cotton insulation used in the building saves one ton of oil a year.

- Q: What are common house thermal insulation materials?

- Can be divided into fibrous, porous, microporous, bubble, granular, layered and many other, here are some of the more common materials are briefly introduced.

- Q: Does water paint spray fire in underground space?

- Waterborne paint itself is waterproof, unlike oil paint as security for.

- Q: How about the appearance of glass wool, mineral wool and asbestos?

- Glass wool is the molten glass fibrosis, the formation of cotton like material, chemical composition of glass, is a kind of inorganic fibers. With good forming, small volume density, thermal conductivity, both thermal insulation, sound-absorbing performance, corrosion resistance, chemical stability.

- Q: What are the common thermal insulation materials?

- Mineral wool is the industrial waste slag as main raw materials by melting, cotton like insulation material made by injection method and centrifugal method: cotton is a natural rock as raw material is made of mineral wool. The commonly used rock such as Xuan Wuyan, diabase, amphibolite etc..Mineral wool characteristics: mineral cotton and products is a high-quality insulation materials, has more than 100 years of production and application history. The utility model has the advantages of light weight, heat preservation, heat insulation, sound absorption, good chemical stability, no burning and corrosion resistance, abundant raw material sources and low cost:

- Q: What kinds of fire retardant coatings are there in steel structures?

- Because this type of ultra-thin fireproof paint coating, making use of thick and thin fire retardant coating for steel structure is greatly reduced, thereby reducing the total cost of the project, the steel structure has been effective fire protection, fire effect is very good.

- Q: What is the difference between ordinary slag wool rock wool board and basalt rock wool board?

- Rock wool and slag wool, chemical composition and acidity coefficient comparison in our country, the main raw material for blast furnace slag slag cotton general or other metallurgical slag, the main raw material for rock wool basalt or diabase, the chemical composition of the differences between them are larger (

- Q: Is the calorimeter for building materials calorific value?

- Calorific value calorimeter for building materials is used to determine the calorific value of building combustible materials such as stone, wood, concrete, and even dispersed mineral wool and polymers. [standard] group will oxynitride calorimeter specimen is placed in the specific quality of a constant volume, in order to test the temperature rise test as the foundation, considering all the heat loss and latent heat of vaporization, heat of combustion calculation sample.

Send your message to us

Rock Wool Blanket and Board Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches