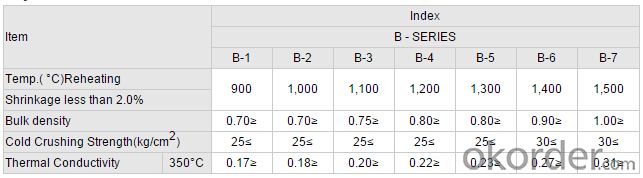

Insulating Fire Brick - Refractory JM Mullite Insulation Brick B-2

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Mullite Insulating Fire Brick JM 23

OKORDER Series Insulating Bricks

OKORDER series insulating bricks are a kind of highly efficient, energy saving, low-carbon, environmental protection advanced products which are manufactured according to ASTM standard. OKORDER series products are the best lining and insulation materials in all types of industrial furnaces in the field of Metallurgy, Aluminum, Petrochemical, Ceramics, Power and Glass. They can be applied as heat insulation or no-melt erosion parts of the working layer. The products have been widely used in the following furnaces and achieved satisfactory results.

Application of Insulating Bricks

Metallurgy industry: Blast furnace, Hot blast stove, Reheating furnace, etc.

Petrochemical industry: Ethylene cracking furnace, Hydrogen production furnace, Primary reformer furnace, Reheating furnace, etc.

Ceramics Industry: Roller kiln, Pusher kiln, etc.

Glass industry: Glass furnace regenerator, etc.

Carbon Industry: Carbon roaster, etc.

Aluminum electrolytic industry: aluminum reduction cells,etc.

Other industries: Tunnel kiln, Shuttle kiln, etc.

Advantages of Insulating Bricks

Low Thermal Conductivity: More porosity brings excellent insulation effect, energy saving.

High Crushing Strength: High crushing strength under thermal state, volume stability.

Low Heat Storage: Little thermal storage when absorb more heat, energy saving effect is obvious.

High Purity: Low content of iron, alkaline and metal impurities.

Accurate Dimension: Precise brick size by machining, cutting and grinding special shapes, expediting bricklaying.

Picture of Insulating Bricks

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. How do you control the products quality?

With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervise.

3. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

4. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

Application:

Insulation brick can be widely used for lining or insulation layers of various industrial furnaces and kilns in metallurgical industry, machine building industry, ceramic industry, chemical industry.

- Q: Can insulating fire bricks be used in the construction of industrial boilers?

- Yes, insulating fire bricks can be used in the construction of industrial boilers. Insulating fire bricks are specially designed to have low thermal conductivity, which means they are excellent at retaining heat and are ideal for applications where high temperatures need to be maintained. In the case of industrial boilers, insulating fire bricks can be used as lining material in the combustion chamber and other areas of the boiler where insulation is required. The use of insulating fire bricks in industrial boilers offers several advantages. Firstly, their low thermal conductivity helps to reduce heat loss, improving the overall energy efficiency of the boiler. This can result in significant cost savings over time. Additionally, insulating fire bricks have a high resistance to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. This is important in boiler applications where the temperature can fluctuate frequently. Furthermore, insulating fire bricks are lightweight and relatively easy to install, making them a convenient choice for construction projects. They can be easily shaped and cut to fit the specific requirements of the boiler, allowing for a precise and efficient installation process. Overall, the use of insulating fire bricks in the construction of industrial boilers is a suitable choice due to their excellent thermal insulation properties, resistance to thermal shock, and ease of installation.

- Q: Can insulating fire bricks be used in cryogenic applications?

- Insulating fire bricks, also known as refractory bricks, serve primarily for high-temperature purposes and find common usage in furnaces and kilns. Nonetheless, when it comes to cryogenic applications involving extremely low temperatures, insulating fire bricks may prove to be unsuitable. Cryogenic temperatures, usually below -150 degrees Celsius (-238 degrees Fahrenheit), present distinctive challenges for materials due to the severe thermal stresses they endure. Insulating fire bricks typically consist of materials like alumina and silica, which possess limited resistance to thermal shock and can become brittle at exceedingly low temperatures. This brittleness exposes them to the risk of cracking and failure under cryogenic conditions. Furthermore, insulating fire bricks exhibit relatively high thermal conductivity, implying that they conduct heat rather efficiently. In cryogenic applications, where minimizing heat transfer is of utmost importance, materials with lower thermal conductivity are preferred. Consequently, insulating fire bricks, with their higher thermal conductivity, may not be the most effective choice for cryogenic applications. Instead, materials with exceptional thermal insulation properties and low thermal conductivity, like aerogels or foams made from silica or carbon, are often favored for cryogenic applications. These materials offer superior thermal insulation and better resistance to extreme temperatures, ensuring efficient and dependable performance in cryogenic environments. In conclusion, while insulating fire bricks find suitability in high-temperature applications, they may not be the optimal selection for cryogenic applications due to their brittleness at low temperatures and relatively high thermal conductivity. Materials specifically designed for cryogenic conditions, such as aerogels or foams, prove to be more suitable for these extreme temperature environments.

- Q: How do insulating fire bricks help to conserve energy?

- Insulating fire bricks contribute to energy conservation in several ways. Firstly, these bricks are crafted from materials with high thermal resistance, enabling them to effectively impede heat transfer. When utilized in the construction of furnaces, kilns, or other heat-generating equipment, they create a protective barrier that prevents heat loss to the surroundings. Consequently, this diminishes the amount of energy required to maintain a consistent temperature within the equipment. Furthermore, insulating fire bricks possess low thermal conductivity, meaning they do not readily conduct heat. Consequently, they impede the transfer of heat from the hot side to the cold side, resulting in minimal heat loss and ensuring that more energy is utilized for its intended purpose, rather than being squandered. Moreover, insulating fire bricks possess a high heat capacity, allowing them to efficiently absorb and retain heat. This characteristic proves advantageous as it aids in stabilizing temperature fluctuations by gradually releasing stored heat over time. Consequently, this reduces the necessity for constant energy input to maintain the desired temperature. To summarize, insulating fire bricks aid in energy conservation by reducing heat loss, minimizing heat transfer, and stabilizing temperature fluctuations. By incorporating these bricks into various heat-generating applications, energy consumption can be significantly decreased, leading to cost savings and a more sustainable utilization of resources.

- Q: Are insulating fire bricks resistant to ammonia gas?

- Yes, insulating fire bricks are generally resistant to ammonia gas. Their high temperature resistance and low thermal conductivity make them suitable for applications involving ammonia gas. However, it is always recommended to refer to the specific manufacturer's specifications and consult with experts to ensure the compatibility of insulating fire bricks with ammonia gas in a particular setting.

- Q: Can insulating fire bricks be installed in both industrial and residential settings?

- Insulating fire bricks can be utilized in both industrial and residential environments. These bricks are specifically engineered to endure extreme temperatures and offer superb insulation, rendering them appropriate for various purposes. In industrial settings, insulating fire bricks are frequently employed in furnaces, kilns, and ovens, as they aid in conserving energy and ensuring stable temperatures. In residential settings, they can be employed in fireplaces, wood-burning stoves, and pizza ovens, enhancing heat retention and promoting safety. Due to their versatility and durability, insulating fire bricks are a dependable option for installations in both industrial and residential settings.

- Q: Can insulating fire bricks be used in the construction of ceramic tile kilns?

- Yes, insulating fire bricks can be used in the construction of ceramic tile kilns. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent insulation properties. They have low thermal conductivity, which means they help to retain heat within the kiln and prevent it from escaping, resulting in more efficient and effective firing of ceramic tiles. Additionally, their lightweight nature makes them easy to handle and install in the kiln structure. Overall, using insulating fire bricks in the construction of ceramic tile kilns can help improve energy efficiency, reduce heat loss, and ensure consistent and controlled firing temperatures.

- Q: Is it possible to recycle broken insulating fire bricks?

- Yes, it is possible to recycle broken insulating fire bricks. Insulating fire bricks are commonly made from materials such as clay and alumina, which can be recycled. The broken bricks can be crushed into small particles or ground into a fine powder, and then mixed with other materials to create new bricks or other construction materials. Additionally, some recycling facilities may accept broken insulating fire bricks and process them for reuse in other industries. Recycling broken insulating fire bricks helps to reduce waste, conserve resources, and minimize the environmental impact associated with manufacturing new bricks from scratch.

- Q: Can insulating fire bricks be used for insulation in ovens and kilns?

- Yes, insulating fire bricks can be used for insulation in ovens and kilns. They are designed to withstand high temperatures and provide excellent thermal insulation, making them an ideal choice for these applications.

- Q: Can insulating fire bricks be used for both residential and commercial purposes?

- Yes, insulating fire bricks can be used for both residential and commercial purposes. Insulating fire bricks are designed to provide excellent insulation and thermal protection, making them suitable for a wide range of applications. In residential settings, these bricks can be used for insulating fireplaces, wood-burning stoves, and pizza ovens, among others. In commercial settings, they are commonly used for kilns, furnaces, boilers, and industrial ovens. The versatility of insulating fire bricks makes them a popular choice for both residential and commercial projects where effective thermal insulation is required.

- Q: Are insulating fire bricks suitable for insulation in gas turbines?

- Yes, insulating fire bricks are suitable for insulation in gas turbines. They have excellent insulating properties and can withstand high temperatures, making them an ideal choice for protecting and insulating the components of gas turbines.

Send your message to us

Insulating Fire Brick - Refractory JM Mullite Insulation Brick B-2

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords