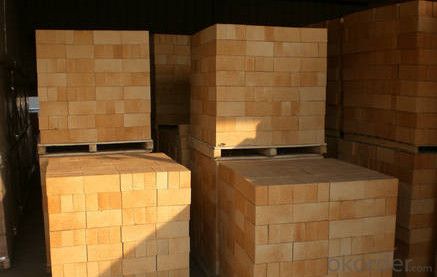

High Alumina Refractory Bricks for Steel Ladle Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So pls stay cool with our quality.

Insulating Fire Brick Technical index

Product No. | IFB70 | IFB60 | IFB50 | IFB40 |

Al2O3 | 68%-72% | 58%-62% | 48%-52% | 38%-40% |

Refractoriness (°C ) | ≥1790 | ≥1790 | ≥1790 | ≥1790 |

Bulk density (g/cm3) | 2.50-2.60 | 2.35-2.45 | 2.20-2.30 | 2.10-2.20 |

Apparent porosity (%) | 22 | 19-22 | 17-20 | 17-20 |

Cold Crushing strength (kg) | 480-510 | 450-480 | 430-450 | 390-430 |

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

FAQs

Q1 |

What’s the transport method? |

A1 | FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo. |

Q2 |

What’s the required payment term? |

A2 | Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation. |

Q3 |

Which country are our products exported to? |

A3 | Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations. |

- Q: In 2016, a few of the traditional refractory materials will be able to survive

- In short, the overall market of refractory enterprises is in a turbulent adjustment process, but the volume is still in place. Elimination is inevitable, as to how many can be eliminated, dare not assert.

- Q: Introduction of high alumina brick

- Three alumina silicate refractory product with a content of two Al2O3 (48%).

- Q: What is the price of the first grade high alumina brick?

- Many factories in Xinmi have high alumina bricks, but they must choose a regular factory. Kuwait refractory level high aluminum brick price at around 1600, the quality of double stable supply

- Q: The cloth blowing is not uniform on the lime kiln refractory brick is damaged it

- People with the shaft kiln cement clinker kiln, because of small size, low calcination temperature, using only Al2O3 containing a single clay brick is 30 ~ 40%, the rotary kiln was improved in the early Yuan faith this experience, use of high alumina brick and clay brick, from 60s onwards, due to large scale kiln and to strengthen the operation of the high temperature parts of kiln lining, alkaline brick masonry is widely used, the main varieties are: magnesia chrome brick, magnesia spinel brick and dolomite brick.

- Q: What are the characteristics of high alumina bricks?

- High thermal stability, fire resistance above 1770. Slag resistance is good, used for masonry steel smelting furnace, glass furnace, cement rotary furnace lining. High R.U.L, low creep high alumina brick with high grade bauxite, fused corundum, fused mullite as main raw material of high-grade refractory materials.

- Q: How to reduce porosity of high alumina brick

- When proportioning, the ratio of coarse to medium to fine is 4:2:4, and the maximum particle size should be no more than 5mm. The mixing order is as follows: first adding coarse particles, then adding sulfite pulp waste liquid, premixed 3min, then adding high aluminum fine powder for mixing. The operation process is coarse and fine particles added in sulfuric acid with crushed pulp waste.In order to reduce the porosity, our company suggested that the single-sided pressure changed to double-sided pressure instead of double-sided pressure, the number of strikes should also vary according to the amount of feeding. If the kiln is fired, the location of the fire hole shall be adjusted so that the middle part is dense, the edge is thin, and the door near the kiln is properly encrypted so that the temperature difference between the furnace top and bottom and the temperature difference between the inside and outside are not greater than 20 degrees.

- Q: Which is better, the soft core or the hard core?

- When the current through the wire, it will produce a magnetic field in the vertical plane space of the wire, if there is a current two wire close by in the same direction, because they produce a magnetic field in the direction is opposite, it will produce a repulsive force is due to the magnetic field force. They will mutually inhibit current intensity of the other party, caused by the reduction of current in the wire, this inhibition of each current intensity, we called wire inductance. When the AC current line frequency is high, the inductance is stronger.

- Q: What kinds of minerals are there in the five major categories of ore crystal chemistry?

- Natural element minerals. Of minerals produced by an element (elementary substance). There are about 90 natural elements in the earth's crust, accounting for 0.1% of the total weight of the earth's crust. Can be divided into metal elements, mainly platinum and copper, silver, gold, etc., non-metallic elements, carbon, sulfur, etc., half metallic elements, arsenic, bismuth and so on.

- Q: Use of high alumina refractory bricks?

- High alumina brick refractory than clay refractory bricks and brick refractory degree are higher, up to 1750~1790 DEG C, which belongs to high-grade refractory materials.

- Q: High alumina brick 80 with which high aluminum cement?

- Which kind should be chosen should be determined according to the conditions of use, life expectancy and cost control. By the way, the quality of masonry is also very influential.

Send your message to us

High Alumina Refractory Bricks for Steel Ladle Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords