Refillable Can Tin Can For Shaving Foam, Aerosal Can

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 300000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

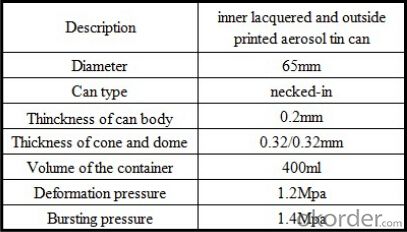

1.Brief description

2.Usage:

suitable for insecticide, air freshener, body spray, lighter refill, car care etc

3.Packing

4.Advantages of us

1.With ISO9001:2008 certification

2. Over 20 years in producing tin cans

3. Annual capacity: over 400 million pcs

4. Introduced the most advanced iron-printing machine from Japan and Germany, also several full-automatic & high-speed(300pc/minute) can-making lines from Europe.

5. Our products include diameter 45mm, 52mm, 57mm, 60mm, 65mm, 70mm, the can height is from 80-300mm differently

5. FAQ

1. Delivery Time:15-25 days, time can be shorten upon customer’s situation

2. Productivity:1,000,000 Cans/Day; 500,000 Printing Sheets/Day

3. MOQ:50,000pcs, but finally upon your size

4. Payment Term: 30% TT in advance, 70% balance against BL copy; 100% by LC at sight

- Q: What are the quality control measures for tinplate production?

- Quality control measures for tinplate production typically include various inspections and tests at different stages of the manufacturing process. Some common quality control measures include: 1. Raw material inspection: The quality of the steel used for tinplate production is assessed, including its chemical composition, thickness, and surface finish. Any deviations from the desired specifications are flagged. 2. Coating inspection: The tin coating applied to the steel is examined for uniformity, adhesion, thickness, and absence of defects like pinholes or scratches. This ensures the protective and aesthetic qualities of the tinplate. 3. Surface inspection: The surface of the tinplate is inspected for any visible defects such as dents, scratches, or irregularities. This ensures the overall quality and appearance of the final product. 4. Dimensional control: Tinplate sheets or coils are measured to ensure they meet the specified dimensions and tolerances. This includes verifying the length, width, thickness, and flatness of the tinplate. 5. Tinplate performance testing: Selected samples are subjected to various mechanical and chemical tests to assess their performance. These tests can include assessments of corrosion resistance, adhesion, hardness, and tin coating integrity. 6. Packaging inspection: The final tinplate products are inspected for proper packaging, labeling, and protection. This ensures that the tinplate reaches customers in good condition and meets their expectations. By implementing these quality control measures, manufacturers can maintain consistent product quality, meet customer requirements, and ensure the reliability and functionality of tinplate products.

- Q: How to test the tightness of tin metal cans?

- A careful observation of empty tank tank bottom edge and welding seam has no air bubbles, where the same parts of continuous bubbles, should be judged as leakage, leakage of the recording time and vacuum degree, and make a mark in the leak site.

- Q: What are the different types of tinplate seams?

- There are three main types of tinplate seams: the lap seam, the double seam, and the triple seam. The lap seam is formed by overlapping the tinplate and soldering the edges together. The double seam involves folding the edges of the tinplate over each other and then crimping them together. Lastly, the triple seam is created by folding the edges of the tinplate over each other twice and crimping them together.

- Q: Can tinplate be used for pharmaceutical blister packaging?

- Yes, tinplate can be used for pharmaceutical blister packaging. Tinplate is a commonly used material for packaging due to its durability, corrosion resistance, and ability to protect the contents from moisture and light. It is a suitable option for pharmaceutical blister packaging, as it helps maintain the integrity and quality of the medication.

- Q: What's the advantage of metal containers in packing tea?

- General metal cans are divided into three kinds of tinplate (also known as: tin iron) tin cans, aluminum cans

- Q: How does tinplate perform in terms of corrosion resistance?

- Tinplate performs exceptionally well in terms of corrosion resistance due to the protective layer of tin that prevents the underlying steel from coming into contact with corrosive elements such as moisture and oxygen.

- Q: What are the advantages of using tinplate packaging?

- Tinplate packaging offers several advantages including excellent durability, corrosion resistance, and ability to maintain product freshness. It is also easily recyclable, offers enhanced product visibility, and can be customized with attractive designs.

- Q: How is tinplate affected by extreme temperatures?

- Tinplate is minimally affected by extreme temperatures due to its high melting point and excellent heat resistance properties. It remains stable and does not undergo significant changes in its physical or chemical properties even in extremely hot or cold conditions.

- Q: What are the common surface coatings for tinplate?

- The common surface coatings for tinplate include tin-free steel, electrolytic tinplate, tin-free steel with organic coatings, and tinplate with lacquered coatings.

- Q: Can tinplate be used for packaging agricultural products?

- Yes, tinplate can be used for packaging agricultural products. Tinplate is a popular choice for packaging due to its durability, resistance to corrosion, and ability to protect against light, moisture, and oxygen. It provides a safe and secure packaging solution for agricultural products, ensuring their freshness and extending their shelf life.

Send your message to us

Refillable Can Tin Can For Shaving Foam, Aerosal Can

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 300000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords