All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is the tin coating on electrolytic tinplate coil applied?

The tin coating on electrolytic tinplate coil is applied through a process called electrolytic deposition. In this process, the tinplate coil is immersed in an electrolyte solution containing tin ions. An electric current is then passed through the solution, causing the tin ions to be attracted to the surface of the coil. As the current continues to flow, a layer of tin gradually forms on the coil, creating the desired tin coating.

How is the tin coating applied to the steel substrate in electrolytic tinplate coil?

The tin coating is applied to the steel substrate in electrolytic tinplate coil through a process called electroplating. The steel substrate is immersed in an electrolyte solution containing tin salts. When an electric current is passed through the solution, tin ions are attracted to the steel surface and deposited onto it, forming a thin, uniform layer of tin coating.

How does the surface treatment of electrolytic tinplate coil affect its adhesion properties?

The surface treatment of electrolytic tinplate coil plays a crucial role in enhancing its adhesion properties. By applying an appropriate surface treatment, such as a chemical passivation layer or an organic coating, the tinplate's surface is modified to promote better adhesion between the tin coating and the base steel. This improved adhesion ensures that the tin layer remains firmly attached to the steel substrate, even under various conditions like mechanical stress, corrosion, or temperature fluctuations. Consequently, the surface treatment significantly enhances the overall durability and performance of the electrolytic tinplate coil.

What are the different packaging options for electrolytic tinplate coil?

Some of the different packaging options for electrolytic tinplate coil include wooden pallets, steel pallets, steel strapping, plastic wrapping, and cardboard boxes. These options help to protect the tinplate coil during transportation and storage and ensure its quality and integrity.

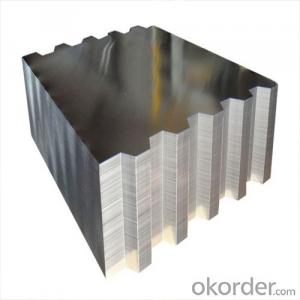

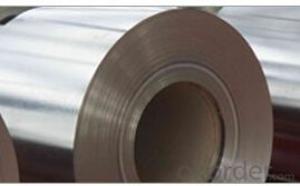

Wholesale Electrolytic Tinplate Coil from supplier in Brunei

Whether you are in the manufacturing, packaging, or construction industry, our Electrolytic Tinplate Coils are suitable for a wide range of applications. We offer various sizes and thicknesses to meet your specific requirements.

Our team of experts is committed to providing exceptional customer service and technical support. We can assist you in selecting the right Electrolytic Tinplate Coils for your projects, offer competitive pricing, and ensure timely delivery to your location in Brunei.

As a subsidiary of CNBM, we have access to a vast network of suppliers and manufacturers, allowing us to source high-quality Electrolytic Tinplate Coils at competitive prices. We prioritize quality and reliability in our products, ensuring that they meet international standards and regulations.

With our years of experience in the Brunei market, we have established strong relationships with local customers and partners. This enables us to understand the unique needs and preferences of the Brunei market, providing you with valuable expertise and insights for your projects.

Whether you need Electrolytic Tinplate Coils for canning, automotive parts, or other applications, our dedicated team is ready to assist you. Contact us today for sales, quotations, and technical support services for Electrolytic Tinplate Coils in Brunei.

Our team of experts is committed to providing exceptional customer service and technical support. We can assist you in selecting the right Electrolytic Tinplate Coils for your projects, offer competitive pricing, and ensure timely delivery to your location in Brunei.

As a subsidiary of CNBM, we have access to a vast network of suppliers and manufacturers, allowing us to source high-quality Electrolytic Tinplate Coils at competitive prices. We prioritize quality and reliability in our products, ensuring that they meet international standards and regulations.

With our years of experience in the Brunei market, we have established strong relationships with local customers and partners. This enables us to understand the unique needs and preferences of the Brunei market, providing you with valuable expertise and insights for your projects.

Whether you need Electrolytic Tinplate Coils for canning, automotive parts, or other applications, our dedicated team is ready to assist you. Contact us today for sales, quotations, and technical support services for Electrolytic Tinplate Coils in Brunei.