Aerosol Can for Hair Spray,Φ57mm, Tinplate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief description

Content: hair spray

Size: 57X260mm

Printing: CMYK printing as Per Customer Design

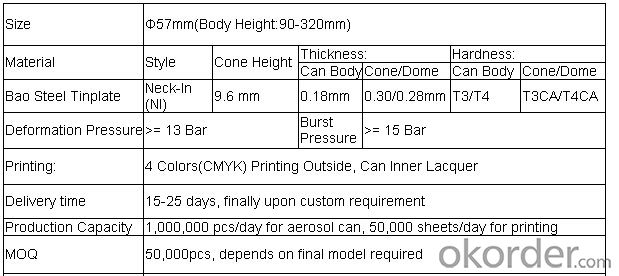

2.Detailed Specification

3.Usage:

suitable for insecticide, air freshener, body spray, lighter refill, car care etc

4.Packing

5.Advantages of our factory

1.With ISO9001:2008 certification

2. Over 20 years in producing tin cans, since 1992 .

3. Annual capacity: over 400 million pcs

4.Introduced the most advanced iron-printing machine from Japan and Germany, also several full-automatic & high-speed

5. Our products include diameter 45mm,52mm,57mm,60mm,65mm,70mm. Can height is from 80-320mm.

6.FAQ

1. Delivery Time:15-25 days, time can be shorten upon customer’s situation

2. Productivity:1,000,000 Cans/Day; 500,000 Printing Sheets/Day

3. MOQ:50,000pcs, but finally upon your size

4. Payment Term: 30% TT in advance, 70% balance against BL copy; 100% by LC at sight

- Q:What are the main applications of tinplate in the automotive industry?

- Tinplate is commonly used in the automotive industry for various purposes, including the production of fuel tanks, oil filters, and battery casings. The main applications of tinplate in the automotive sector are primarily due to its properties, such as corrosion resistance, durability, and formability. These qualities make tinplate an ideal material for ensuring the safety and longevity of automotive components.

- Q:What are the different ways to customize tinplate packaging?

- There are several ways to customize tinplate packaging. These include printing the packaging with custom designs, adding embossing or debossing for texture, applying special finishes like glossy or matte coatings, incorporating special effects like metallic or holographic foils, and using different colors or patterns. Additionally, custom shapes and sizes can be created to suit specific product requirements.

- Q:How does tinplate contribute to sustainability efforts?

- Tinplate contributes to sustainability efforts by being a highly recyclable material. It can be used repeatedly without losing its properties, reducing the need for new resource extraction. Additionally, tinplate is commonly used for food and beverage packaging, which helps preserve products and reduces food waste. Its durability and corrosion resistance also extend the lifespan of products, making it a sustainable choice for various industries.

- Q:How is tinplate tested for quality and performance?

- Tinplate is tested for quality and performance through various methods such as visual inspection, thickness measurement, adhesion testing, corrosion resistance evaluation, and mechanical property analysis. Visual inspection involves assessing the surface for any defects or irregularities. Thickness measurement ensures the tin coating meets the required standards. Adhesion testing checks the bond strength between the tin and base metal. Corrosion resistance evaluation examines the tinplate's ability to withstand corrosion. Mechanical property analysis includes tests for strength, hardness, ductility, and formability to ensure it meets the desired performance requirements.

- Q:How is tinplate used in the production of aerosol valves?

- Tinplate is used in the production of aerosol valves as it provides a durable and corrosion-resistant material for the valve components. It helps to maintain the integrity of the valve, ensuring a reliable and leak-proof seal. Additionally, tinplate can be easily formed into intricate shapes, allowing for the precise design and functionality required in aerosol valves.

- Q:What are the regulations regarding the use of tinplate in food packaging?

- The regulations regarding the use of tinplate in food packaging vary by country. In the United States, the Food and Drug Administration (FDA) regulates the use of tinplate in food packaging materials. Tinplate must comply with the FDA's requirements for food contact substances, ensuring that it is safe and does not transfer harmful substances to the food. Additionally, there may be specific regulations and standards set by other countries or regions, so it's important to consider the specific jurisdiction when determining the regulations for tinplate use in food packaging.

- Q:How does tinplate packaging contribute to product protection against light?

- Tinplate packaging contributes to product protection against light by providing a highly effective barrier that prevents light from reaching the product. The tin coating on the steel substrate acts as a reflective layer, reducing the amount of light transmission. This helps to shield the product from harmful UV radiation and other forms of light that can cause degradation, discoloration, or spoilage. Additionally, tinplate packaging can be further enhanced with additional protective coatings or lacquers that provide an additional layer of defense against light exposure, ensuring the product remains intact and protected.

- Q:How is tinplate used in the manufacturing of electrical components?

- Tinplate is commonly used in the manufacturing of electrical components due to its corrosion resistance and excellent electrical conductivity. It is often formed into thin sheets and utilized as a protective coating on copper or other metal surfaces to prevent oxidation and ensure prolonged durability. Additionally, tinplate can be shaped into intricate forms, such as cans or enclosures, to house electrical circuits and provide insulation. Overall, tinplate plays a crucial role in safeguarding the functionality and longevity of electrical components.

- Q:What are the common safety features for tinplate packaging?

- Common safety features for tinplate packaging include: 1. Tamper-evident closures: Tinplate packaging often includes tamper-evident closures such as seals or breakable tabs that indicate if the product has been opened or tampered with. 2. Child-resistant closures: Many tinplate packages are designed with child-resistant closures to prevent young children from accidentally accessing potentially harmful products. 3. Sturdy construction: Tinplate packaging is known for its durability and strength, providing a protective barrier for the contents inside. 4. Chemical resistance: Tinplate packaging is typically resistant to chemicals, preventing any harmful substances from leaching into the product. 5. Recyclability: Tinplate packaging is highly recyclable, making it an environmentally-friendly choice. This feature ensures that the packaging is disposed of properly, reducing waste and environmental impact. 6. Printed warnings and instructions: Tinplate packaging often includes printed warnings and instructions to inform consumers about any potential hazards associated with the product and how to use it safely. These safety features help to ensure that tinplate packaging protects the product, prevents accidents or tampering, and provides necessary information to consumers for safe usage.

- Q:What are the advantages of using tinplate for household appliances?

- There are several advantages of using tinplate for household appliances. Firstly, tinplate is highly resistant to corrosion, making it ideal for appliances that come in contact with water or other liquids. This corrosion resistance ensures the longevity of the appliance, reducing the need for frequent replacements. Secondly, tinplate has excellent heat resistance properties, making it suitable for appliances that generate high temperatures. This heat resistance allows for efficient heat transfer and prevents warping or damage to the appliance. Additionally, tinplate is lightweight yet sturdy, making it easy to handle and transport while maintaining durability. Lastly, tinplate is a sustainable material as it is 100% recyclable, reducing environmental impact and promoting a circular economy.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aerosol Can for Hair Spray,Φ57mm, Tinplate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords