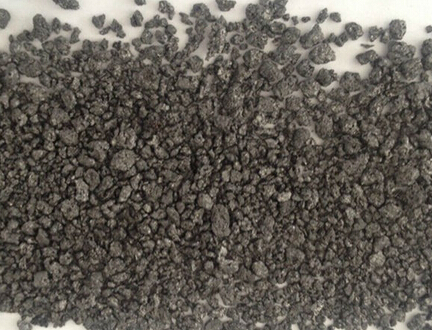

Recarburizer Graphite Petroleum Coke 93% 94% Calcined anthracite

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 500000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

Low Sulphur Calcined Petroleum Coke/Calcined Anthracite /CPC

We can manufacture the high quality product according to customers' requirements or drawings

Advantage:

- Reduce energy consumption

- Reduce recarburizer consumption

- Reduce scrap rate

- Reduce tap to tap time

- Reduce scrap rate

We can offer carburant in differnt types,whenever you need,just feel free to contact us

Data Sheet:

NO. | Fixed Carbon | Sulphur | Moisture | Volatile | Graininess |

>= | <=< span=""> | <=< span=""> | <=< span=""> | Granularity distribution 90% | |

Oz1011 | 98.50% | 0.05% | 0.50% | 0.50% | 1-5mm |

Oz1012 | 98.50% | 0.50% | 0.50% | 0.80% | 1-5mm |

Oz1013 | 95.00% | 0.30% | 0.26% | 1.14% | 1-4mm |

Oz1014 | 90.00% | 0.30% | 0.30% | 0.90% | 1-5mm |

Oz1015 | 80.00% | 0.20% | 1.30% | 3.50% | 1-5mm

|

- Q: What is fullerene?

- Fullerene refers to a unique form of carbon molecule that is composed of interconnected carbon atoms forming a cage-like structure. It was first discovered in the 1980s and has since attracted significant scientific interest due to its distinct properties and potential applications in various fields such as electronics, medicine, and materials science.

- Q: Does alumina react with carbon?

- NotThe smelting of Al in industry can only be done by electrolysis. Even at high temperatures, the reducibility of C is not as strong as Al, and the melting point of Al2O3 is very high. At this temperature, C has been gasified

- Q: What is carbon fixation in biology?

- Carbon fixation is the process by which carbon dioxide from the atmosphere is converted into organic compounds by plants, algae, and some bacteria. This process is crucial for the production of organic matter and the maintenance of a stable carbon cycle on Earth.

- Q: What are the consequences of increased carbon emissions on social inequality?

- Increased carbon emissions have profound consequences on social inequality. The primary consequence is the exacerbation of existing inequalities, particularly in disadvantaged communities. Firstly, the effects of climate change, driven by carbon emissions, disproportionately impact marginalized communities, including low-income neighborhoods and developing countries. These communities often lack the resources and infrastructure necessary to withstand extreme weather events, such as hurricanes or flooding, resulting in greater vulnerability and loss of livelihoods. Secondly, the economic consequences of carbon emissions, such as rising energy costs and reduced agricultural productivity, further widen the gap between the rich and the poor. Affluent individuals may be able to adapt to these changes, while those with limited financial resources struggle to cope, leading to increased poverty and socio-economic disparities. Moreover, increased carbon emissions contribute to health disparities. Polluted air, resulting from carbon emissions, disproportionately affects low-income neighborhoods, where industrial plants and highways are often located. This leads to higher rates of respiratory diseases and other health issues among marginalized communities, exacerbating existing health inequalities. Furthermore, the impacts of climate change, driven by carbon emissions, can lead to forced displacement and migration. As environmental conditions deteriorate, communities may be forced to relocate, often resulting in social disruption and increased competition for resources. This can further marginalize vulnerable populations and create conflicts over land and access to resources. Lastly, the consequences of carbon emissions on social inequality extend globally. Developing countries, which contribute less to carbon emissions but bear a disproportionate burden of the impacts, face significant challenges in addressing climate change. Limited resources and technological capabilities hinder their ability to adapt and mitigate the effects, perpetuating global inequalities. In conclusion, increased carbon emissions have grave consequences on social inequality. They worsen existing disparities, particularly affecting marginalized communities, through the disproportionate impacts of climate change, economic hardships, health disparities, forced displacement, and global inequalities. Addressing carbon emissions and climate change is crucial not only for environmental sustainability but also for promoting social justice and reducing social inequality.

- Q: How does carbon affect the quality of drinking water?

- Carbon can affect the quality of drinking water through two main mechanisms: activated carbon filtration and carbon dioxide (CO2) absorption. Activated carbon filtration is commonly used in water treatment processes to remove organic contaminants, chemicals, and odors, improving the taste and odor of drinking water. On the other hand, excessive dissolved carbon dioxide in water can make it acidic and affect the pH level, potentially making it corrosive and altering the taste. However, carbon itself is not harmful to human health and can be beneficial in certain forms, such as in the form of activated carbon filters.

- Q: How does carbon dioxide affect climate change?

- Carbon dioxide (CO2) affects climate change primarily through the greenhouse effect. When CO2 is released into the atmosphere, it acts as a greenhouse gas, trapping heat from the sun and preventing it from escaping back into space. This phenomenon leads to an increase in global temperatures, known as global warming, and contributes to climate change. The excessive buildup of CO2 in the atmosphere is primarily caused by human activities, such as burning fossil fuels and deforestation, which have intensified the greenhouse effect and accelerated climate change.

- Q: What is carbon nanocomposite?

- Carbon nanocomposite refers to a type of material that combines carbon nanotubes or graphene with a matrix material, such as polymers or metals, to form a composite material. The carbon nanotubes or graphene are typically added in small amounts, often in the form of nanoparticles, to enhance the mechanical, electrical, and thermal properties of the composite material. Carbon nanotubes are cylindrical structures made up of carbon atoms arranged in a hexagonal lattice, while graphene is a single layer of carbon atoms arranged in a two-dimensional lattice. These carbon-based materials possess exceptional properties, such as high strength, electrical conductivity, and thermal conductivity. When incorporated into a composite material, these properties can be transferred to the overall structure, resulting in improved performance. The use of carbon nanocomposites has been explored in various industries and applications. In aerospace, for example, these materials have been investigated for their lightweight and high-strength properties, which could potentially enhance the fuel efficiency and durability of aircraft components. In electronics, carbon nanocomposites have shown promise for developing high-performance sensors, conductive films, and energy storage devices. Additionally, they have been studied for their potential applications in medical devices, automotive parts, and energy storage systems. Overall, carbon nanocomposites offer the opportunity to create materials with enhanced properties by leveraging the unique characteristics of carbon nanotubes or graphene. However, the production and scalability of these materials still pose challenges, and further research is needed to optimize their performance and cost-effectiveness for various applications.

- Q: What are the effects of carbon emissions on the stability of desertification?

- Desertification is significantly impacted by carbon emissions, which arise from human activities such as burning fossil fuels and deforestation, releasing carbon dioxide and other greenhouse gases into the atmosphere. These emissions contribute to the global warming phenomenon, which in turn leads to various adverse effects on desertification. One major consequence of carbon emissions is the alteration of precipitation patterns. As the planet warms, the evaporation rate rises, causing more moisture to be held in the atmosphere. Consequently, there is reduced rainfall in numerous regions, particularly in arid and semi-arid areas that are already prone to desertification. The scarcity of water exacerbates the dry conditions, thereby facilitating and intensifying desertification. Additionally, the higher temperatures resulting from carbon emissions contribute to the acceleration of soil erosion. As the land heats up, it becomes more susceptible to erosion caused by wind and water. This erosion leads to the loss of topsoil, which is vital for plant growth and stability. Without a stable layer of topsoil, vegetation struggles to establish and survive, ultimately causing the expansion of deserts. Furthermore, carbon emissions also impact plant communities' health and productivity. While increased levels of carbon dioxide can stimulate plant growth in certain cases, it often results in the proliferation of invasive species that are better adapted to the changing conditions. These invasive species outcompete native plants, diminishing biodiversity and further destabilizing the ecosystem. Additionally, as desertification progresses, the loss of plant cover reduces the capacity to sequester carbon, leading to even higher carbon dioxide levels in the atmosphere. In conclusion, carbon emissions have detrimental effects on desertification's stability. They disrupt precipitation patterns, accelerate soil erosion, reduce plant productivity, and diminish the capacity to sequester carbon. To mitigate these impacts and prevent further progression of desertification, it is crucial to reduce carbon emissions through sustainable practices and conservation efforts.

- Q: What are the meanings of carbon, graphite, burr, two cuts and four cuts in steel?.

- Carbon element; carbon is carbon steel, round steel, Primeton is end of carbon steel, which is common round, is construction steel.Flash is to flash, or two bending. Two cuts; one cut two on average, three segments, four cuts; an average cut of four, and five segments. The back is industry talk.

- Q: What are the different types of carbon-based air pollutants?

- Air pollution is caused by various types of carbon-based pollutants. Some examples include: 1. Carbon Monoxide (CO): This gas is produced when fossil fuels like gasoline, coal, and wood are incompletely burned. It is highly toxic and can be harmful to human health, especially when inhaled in large amounts. 2. Carbon Dioxide (CO2): This is a greenhouse gas that occurs naturally in the Earth's atmosphere. However, human activities like burning fossil fuels and deforestation have significantly increased its levels, leading to climate change and global warming. 3. Volatile Organic Compounds (VOCs): These are organic chemicals that easily evaporate at room temperature. They are released into the air by various sources such as paints, solvents, gasoline, and industrial processes. VOCs contribute to the formation of ground-level ozone, which is a major component of smog and can harm human health. 4. Methane (CH4): Another greenhouse gas, methane is primarily produced by the decomposition of organic materials in landfills and the extraction and transportation of natural gas. Methane has a much higher warming potential than carbon dioxide. 5. Polycyclic Aromatic Hydrocarbons (PAHs): These chemicals are formed when organic materials like coal, oil, and gas are incompletely burned. PAHs are released into the air through vehicle exhaust, industrial processes, and the burning of fossil fuels. They are known to be cancer-causing and have adverse effects on human health. 6. Formaldehyde (HCHO): This colorless gas is used in the production of resins, plastics, and certain building materials and household products. It is released into the air through fuel combustion, cigarette smoke, and the release of certain products. Formaldehyde is a respiratory irritant and can cause allergic reactions and other health problems. These are just a few examples of carbon-based pollutants that contribute to air pollution. It is crucial to reduce emissions of these pollutants by adopting cleaner technologies, energy-efficient practices, and promoting the use of renewable energy sources. This will help minimize their negative impacts on human health and the environment.

Send your message to us

Recarburizer Graphite Petroleum Coke 93% 94% Calcined anthracite

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 500000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords