16 Gauge 4 X 8 Sheets of Aluminum - Re-Rolling Aluminum Circle for Deep Drawing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

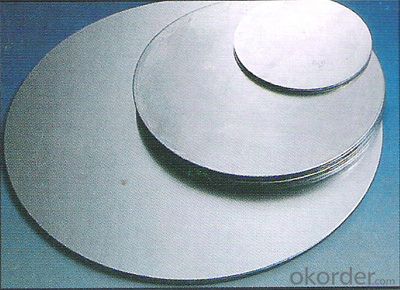

1.Structure of Re-Roling Aluminium Circle for Deep Drawing

Re-Roling Aluminium Circle for Deep Drawing is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Re-Roling Aluminium Circle for Deep Drawing

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: I want to use one aluminum bottle, rather than several plastic ones. And this may sound stupid, but will an aluminum water bottle be safe to put in the fridge?

- yea it would be safe because my brother does it all the time. Also you can just refill your plastic bottles with water and put in the fridge and the freezer because I do that all the time and i'm still using the same water bottles and they are in great shape and the fridge and freezer keep my water nice in cold.

- Q: This question asks for a comparison between aluminum sheets and other roofing materials in terms of their characteristics and performance.

- <p>Aluminum sheets are lightweight and highly durable, offering excellent resistance to corrosion and weathering. They are energy-efficient, reflecting heat and reducing cooling costs. Compared to materials like asphalt shingles, aluminum is more expensive but lasts longer, with a lifespan of 40-50 years. Unlike clay or concrete tiles, aluminum is less prone to breakage and is easier to install. It also doesn't rot or warp like wood, and it's fire-resistant. However, it can be noisy during rain and is less visually appealing than some other materials, but its modern and sleek appearance can be a design advantage.</p>

- Q: Are aluminum sheets suitable for construction purposes?

- Yes, aluminum sheets are suitable for construction purposes. They are lightweight, durable, and resistant to corrosion, making them ideal for various construction applications such as roofing, cladding, and structural components. Additionally, aluminum sheets offer good thermal and electrical conductivity, making them suitable for applications where these properties are required.

- Q: What are the different alloy compositions available for aluminum sheets?

- Aluminum sheets offer a variety of alloy compositions, each with its own distinct properties and applications. There are several common alloy compositions to consider. Firstly, we have 1100, which stands out for its exceptional corrosion resistance and high thermal conductivity. This alloy finds its place in chemical equipment, heat exchangers, and food processing equipment. Next, 3003 presents good formability, moderate strength, and excellent corrosion resistance. It is commonly employed in packaging, tanks, and architectural applications. Moving on to 5052, this alloy boasts high strength and good formability. It is often utilized in marine applications, as well as in aircraft and automotive parts. For those seeking excellent strength, good formability, and high corrosion resistance, 6061 is the alloy of choice. It is commonly found in structural applications like bridges, buildings, and transportation equipment. Lastly, we have 7075, known for its remarkably high strength and good machinability. Aerospace applications, as well as high-stress parts in the automotive and sporting goods industries, benefit from this alloy. These examples merely scratch the surface of the numerous alloy compositions available for aluminum sheets. The selection of the appropriate alloy hinges on specific application requirements, such as strength, corrosion resistance, formability, and machinability.

- Q: which kind of material won't influence magnet attracting iron nail? Does copper sheet or aluminum sheet influence it?

- Copper coil will impede magnetic penetration. People separate the magnet from the workpiece of machine tool to avoid magnetic short circuit and attraction loss, making magnetic line of force go through the workpiece. An opening copper bush is added into the iron core of magnetic closing coil or opening solenoid to avoid the iron core being attracted on the external iron piece and stop operation. The opening is for avoiding eddy formulation and short circuit, iron core in copper bush is the ruled magnetic circuit.

- Q: This question asks for a list of adhesive types that are suitable for bonding aluminum sheets. It is important to provide a variety of options to give a comprehensive answer.

- <p>There are several types of adhesives used for bonding aluminum sheets together, including epoxy resins, which offer strong adhesion and resistance to heat and chemicals; polyurethane adhesives, known for their flexibility and durability; acrylic adhesives, which provide good adhesion and are easy to use; cyanoacrylates or 'super glues,' which bond quickly and are great for small, precise applications; and silicone adhesives, which are excellent for high-temperature applications and offer flexibility. Each type has its own advantages and is chosen based on the specific requirements of the bonding task, such as strength, flexibility, and resistance to environmental factors.</p>

- Q: What is the classification of 6061106070 aluminum plate, which respectively represent what it means to ask God for help

- 6061, 1060, 7075, these we call "aluminum plate" brand, six beginning, we usually call six Department of aluminum, the beginning of a department of aluminum is pure aluminum, there are 1050, 1060, 1100, etc., aluminum content is more than 99%. Two at the beginning of the Al Cu alloy, 2024 and 2017, less domestic, belongs to aviation aluminum, in addition to the seven lines is the two most hard.

- Q: What is the standard thickness of aluminum sheets used for exterior building applications?

- <p>The typical thickness of aluminum sheets used for building exteriors ranges from 0.7mm to 1.2mm. This range is suitable for applications such as facades, cladding, and roofing. The specific thickness can vary depending on the structural requirements, wind loads, and the overall design of the building. Thicker sheets may be used for more robust structures or in areas with higher wind pressures, while thinner sheets can be used for lighter applications or when a more aesthetically pleasing finish is desired.</p>

- Q: Which is better aluminum or stainless steel?

- They each have their own advantages and disadvantages. Which one is better depends entirely on what you're USING it for! -Aluminum has a better strength to weight ratio. In other words, while it is not as strong as steel, the fact that it weighs less than half as much makes up for it's lower strength. This is why most airplanes are made of aluminum. -Aluminum is generally more corrosion resistant than all but the most expensive stainless steels. However under certain condition it may corrode rapidly with catastrophic results. -Al is usually less expensive than stainless steel (SS), Though it is 2-4 times more expensive than ordinary (non-stainless) steels. -Al is fairly soft and easier to cut, saw, carve, drill, and machine than steels. (SS is very difficult to work with due to it's excellent abrasion resistance.) -Al is an excellent conductor of heat. This is why it's used for car radiators and air conditioning units, and for pots and pans. -Al is a very good conductor of electricity. Because of it's high conductance, light weight, and corrosion resistance, Al is used for high-voltage overhead power lines. -Stainless steel is stronger than Al, if weight is not a consideration. (In this respect, since Al is weaker, a pipe that could handle the same water pressure would need to be thicker if it was made of Al, So in many cases you can save money on materials by using SS) -SS is easy to weld. (welding Al is very difficult.) -SS can be used at much higher temps. than Al; which becomes very soft above about 400 degrees. -SS is more impact resistant than Al, in other words, it is more ductile. -SS is much more resistant to wear and abrasion, which as I said before makes it difficult to work with.

- Q: How do aluminum sheets perform in terms of weather resistance?

- Aluminum sheets possess remarkable properties when it comes to resisting weather. Their innate ability to resist corrosion enables them to endure exposure to various weather conditions without deteriorating or rusting, making them highly suitable for outdoor uses. The natural formation of a protective oxide layer on the surface of aluminum acts as a barrier against moisture, preventing the metal from reacting with oxygen and thereby reducing the risk of corrosion. Moreover, aluminum sheets exhibit a high resistance to UV radiation, which means they can withstand prolonged exposure to the sun without fading or discoloration. In conclusion, aluminum sheets exhibit outstanding weather resistance and are a dependable choice for a wide range of outdoor applications, such as roofing, siding, and outdoor signage.

Send your message to us

16 Gauge 4 X 8 Sheets of Aluminum - Re-Rolling Aluminum Circle for Deep Drawing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords