Aluminum Deep Drawing Quality Discs and Circles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminum Discs circles with Deep Drawing Quality Description

• Product: Aluminim Circle

• Application: It is used in cookware, engineering, lighting purpose, fried pans, non-sticky pans, cooking pots, kettles, hard anodize cook wire, pressure cooker and house hold utensils, reflector of the light, etc

• Advantage: Deep drawing and hard anodizing quality Aluminum Circle Sheet can be supplied. Our Aluminum Circle is RoHS and REACH compliance and uses well-protected packing. Our circles are excellent material for producing cookware, utensil, pots, pans and kettles.

2.Main Features of the Aluminum Discs circles with Deep Drawing Quality

• High manufacturing accuracy

• Smooth surface

• No waves

• High strength of extension and yield

• Well packaged

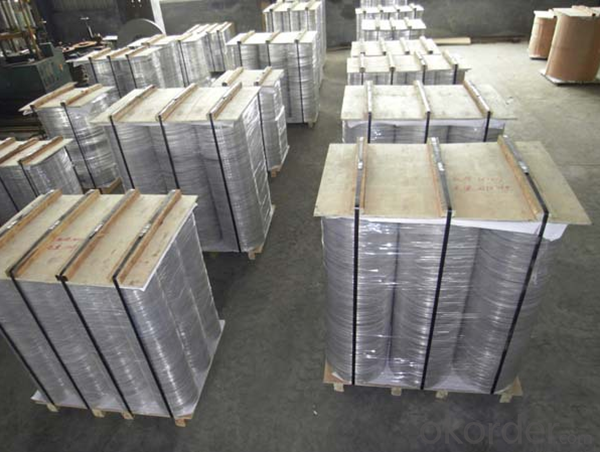

3. Aluminum Discs circles with Deep Drawing Quality Images

4.Aluminum Discs circles with Deep Drawing Quality Specification

Alloy | AA1050,AA1060,AA1100 AA3003etc. |

Temper | O,H14 |

Thickness | 0.5MM-4MM |

Diagonal | 100-1200MM |

Standard | GB/T 3880-2006 |

5.FAQ of Aluminum Discs circles with Deep Drawing Quality

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: Is it possible to utilize recycled aluminum for the production of cars or other types of vehicles?

- <p>Yes, recycled aluminum can be used to make cars and other vehicles. It is common practice in the automotive industry to use recycled aluminum in the manufacturing process due to its lightweight and strong properties. Recycled aluminum requires less energy to produce than new aluminum, making it more sustainable. It is used in various parts of vehicles, including engine components, body panels, and wheels. The use of recycled aluminum not only reduces waste but also contributes to energy savings and carbon emission reductions in vehicle production.</p>

- Q: Does aluminum undergo corrosion when exposed to seawater?

- <p>Aluminum does not typically corrode in seawater due to its natural protective oxide layer. When exposed to air or water, aluminum forms a thin, dense layer of aluminum oxide on its surface, which prevents further corrosion. This passive layer makes aluminum highly resistant to corrosion in most environments, including seawater. However, under certain conditions such as in the presence of certain chemicals or extreme pH levels, the protective layer can be compromised, leading to corrosion. Generally, though, aluminum is considered a good material for marine applications because of its corrosion resistance.</p>

- Q: Is it possible to utilize aluminum to enhance the durability and efficiency of batteries?

- <p>Yes, aluminum can be used to make batteries more durable and efficient. Aluminum's lightweight, high conductivity, and corrosion resistance make it a favorable material for battery components. In particular, aluminum-air batteries leverage aluminum's ability to provide a high energy density. Additionally, research is ongoing to improve lithium-ion batteries by using aluminum as a component in the anode, which can potentially increase energy storage capacity and lifespan. However, challenges such as aluminum's reactivity and the development of efficient recycling methods must be addressed for widespread adoption in battery technology.</p>

- Q: Is it possible to employ aluminum for the creation of innovative packaging materials?

- <p>Yes, aluminum is highly suitable for making new types of packaging materials due to its lightweight, malleability, and corrosion resistance. It is often used in food and beverage cans, pharmaceutical packaging, and even flexible packaging films. Aluminum's recyclability also makes it an environmentally friendly choice for sustainable packaging solutions. Innovations in aluminum packaging continue to emerge, focusing on improved barrier properties, lighter weight, and enhanced recycling capabilities.</p>

- Q: This question asks for a brief explanation of the process of recycling aluminum.

- <p>Aluminum recycling involves several steps. First, aluminum waste is collected and sorted. It is then cleaned to remove any contaminants. The cleaned aluminum is melted in a furnace at high temperatures, which is an energy-efficient process as aluminum has a lower melting point compared to other metals. The molten aluminum is then poured into molds to form new products. This process is highly sustainable as it saves energy and reduces waste, with recycled aluminum requiring only 5% of the energy needed to produce new aluminum from raw materials. Recycled aluminum maintains its quality, making it an ideal material for continuous recycling.</p>

- Q: What is the primary application of aluminum in various industries and everyday life?

- <p>Aluminum is most commonly used in the manufacturing of cans and packaging materials due to its lightweight, corrosion resistance, and recyclability. It is also extensively used in construction for window frames, roofing, and facades. In transportation, aluminum is a key material in the production of vehicles, particularly in the aerospace industry for aircraft and automotive industry for car bodies, due to its strength-to-weight ratio. Additionally, it is used in electrical components and electronics due to its good conductivity and malleability.</p>

- Q: Is aluminum a material that can be utilized in medical or pharmaceutical applications?

- <p>Yes, aluminum is used in medicine and pharmaceuticals, primarily in the form of aluminum salts. It is used as an adjuvant in vaccines to enhance the body's immune response. Aluminum compounds are also used as antacids to neutralize stomach acid and in some medications as a buffering agent. However, its use is regulated due to potential health concerns, and it's important to note that aluminum is not used in direct contact with the body for extended periods due to its potential toxicity.</p>

- Q: Explain the relationship between aluminum and electrum, if any.

- <p>Aluminum and electrum are two distinct metals with no direct relationship. Aluminum is a lightweight, silvery-white metal that is the most abundant metallic element in the Earth's crust. It is known for its corrosion resistance and is widely used in various industries. Electrum, on the other hand, is a naturally occurring alloy of gold and silver, valued for its unique properties and historical significance. While both metals are used in various applications, they are chemically and physically different and do not have a direct connection.</p>

- Q: This question asks for methods to decrease the intake or contact with aluminum, a common element that can have health implications if exposed to in large amounts.

- <p>To reduce aluminum exposure, consider the following strategies: 1) Use a stainless steel or glass water bottle instead of aluminum cans. 2) Avoid non-stick cookware with aluminum as a base layer. 3) Choose natural deodorants and antiperspirants without aluminum compounds. 4) Opt for glass or stainless steel food storage containers over aluminum foil or cans. 5) Limit consumption of processed foods, as they often contain aluminum-based additives. 6) Filter your drinking water to remove aluminum. 7) Be mindful of personal care products and choose those free from aluminum. By implementing these changes, you can significantly lower your daily aluminum intake.</p>

- Q: This question asks whether the energy consumption for producing recycled aluminum is lower compared to the production of new aluminum.

- <p>Yes, producing recycled aluminum requires significantly less energy than producing new aluminum. Recycling aluminum uses only about 5% of the energy needed to produce primary aluminum from bauxite ore. This is because recycling involves melting and recasting the metal, which is a much less energy-intensive process than mining, refining, and smelting new aluminum. As a result, recycling aluminum helps conserve energy and reduces greenhouse gas emissions associated with aluminum production.</p>

Send your message to us

Aluminum Deep Drawing Quality Discs and Circles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords