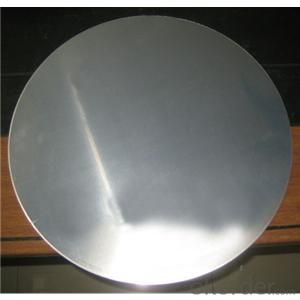

Aluminum 18 Gauge Flat Circle 1070/1060/1050 for Spinning, Pressing, Deep Drawing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Specifications of Aluminium Circles :

Aluminium circle

1.Bright surface, no scratch

2.Deep drawing

3.Customized packing ways are welcomed

4.High quality

Aluminium Circles :

1) Alloy: 1050, 1060, 1070, 1100, 1200, 3003, 3004, 3105 , 5005, 5052, 6061, 8011

2) Temper: O, H12, H14, H16, H18, H22, H24, H26, H32

3) Thickness: 0.30-4.00mm

4) Diameter: 100-980mm

5) Dimensions can be produced according to clients' specifications

6) Good plasticity, conductivity

7) Generally used in industrial and construction applications

l Packaging & Delivery

Packaging detail: Seaworthy Export Standard Wooden Pallet

Delivery detail: About 25 days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

The business scope of CNBM covers from manufacturing and sales of a series of building materials to scientific research and design, import and export trade. In many of these fields, CNBM is playing the leading role.

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Name:Amanda

Email:amandaqian@okorder.com

- Q: This question asks about the interaction between aluminum and electromagnetic radiation, specifically how aluminum influences or is affected by such radiation.

- <p>Aluminum has a high electrical conductivity and is a good reflector of electromagnetic radiation. It reflects a wide range of frequencies, including visible light, ultraviolet, and infrared radiation. Due to its reflective properties, aluminum is used in applications such as reflective coatings for insulation and mirrors. It also has the ability to shield against electromagnetic radiation, making it a common material in the construction of Faraday cages, which are used to block external electromagnetic fields. Aluminum's effect on electromagnetic radiation is primarily through reflection and shielding, rather than absorption or transmission.</p>

- Q: Is it possible to recycle aluminum within the context of car battery recycling facilities?

- <p>Yes, aluminum can be recycled in a car battery recycling facility. Car batteries contain aluminum components, and recycling facilities are equipped to separate and recycle aluminum from other materials. The process typically involves disassembling the batteries, separating the aluminum casings from the lead acid, and then melting the aluminum for reuse. This not only conserves resources but also reduces the environmental impact of battery waste.</p>

- Q: This question asks for a comparison of the pros and cons of using aluminum sheets as a roofing material.

- <p>Advantages of using aluminum sheets for roofing include their lightweight nature, which reduces structural load; corrosion resistance, making them suitable for coastal areas; and low maintenance requirements. They are also energy-efficient, reflecting heat and reducing cooling costs. Disadvantages include the potential for dents and damage from hail or heavy impacts, and they can be more expensive than some other roofing materials. Additionally, aluminum can be noisy during rain, and it may require more frequent replacement compared to some other materials due to its lighter gauge.</p>

- Q: This question asks about the impact of adding silicon to aluminum alloys on their characteristics.

- <p>Adding silicon to aluminum alloys significantly enhances their properties. Silicon increases the alloy's strength and hardness, making it more durable. It also improves the alloy's resistance to corrosion, particularly in harsh environments. The addition of silicon can also reduce the melting point of the alloy, which can be beneficial for casting processes. However, it should be noted that excessive silicon content can lead to a decrease in ductility and workability of the alloy. Overall, silicon is a common alloying element used to improve the mechanical properties and performance of aluminum alloys in various applications.</p>

- Q: Explain the distinction between pure aluminum and aluminum alloys, focusing on their composition and properties.

- <p>Pure aluminum is composed of aluminum alone, with a high degree of purity, typically over 99%. It is soft, malleable, and has good thermal and electrical conductivity. Aluminum alloys, on the other hand, are made by combining aluminum with other elements such as copper, magnesium, or silicon to enhance their strength, durability, and resistance to corrosion. These alloys are harder than pure aluminum and can be tailored for specific applications, making them more versatile for industrial use.</p>

- Q: Explain how the inclusion of copper in aluminum alloys influences their strength and ductility.

- <p>Adding copper to aluminum alloys significantly increases their strength, particularly in the form of tensile and yield strength. Copper acts as a hardening agent, creating a more rigid structure within the alloy. However, this increase in strength often comes at the expense of ductility. As copper content rises, the ductility of the aluminum alloy decreases because copper reduces the alloy's ability to deform under stress without fracturing. The balance between strength and ductility is crucial in alloy design, as higher strength alloys may be less suitable for applications requiring formability and flexibility.</p>

- Q: Is it possible to utilize recycled aluminum in the manufacturing of automobiles and other types of vehicles?

- <p>Yes, recycled aluminum can be used to make automobiles and other vehicles. It is a common practice as aluminum is highly recyclable and retains its properties even after multiple recycling processes. Using recycled aluminum reduces the need for new aluminum production, which is energy-intensive, and contributes to sustainability efforts. Recycled aluminum is often used in vehicle components such as engine parts, body panels, and wheels, due to its lightweight, strength, and corrosion resistance.</p>

- Q: This question asks about the process of producing aluminum, a common metal known for its lightweight and corrosion resistance.

- <p>Aluminum is made through a process called electrolysis. The primary source of aluminum is bauxite ore, which is first refined to produce aluminum oxide. This aluminum oxide is then dissolved in a molten cryolite bath and subjected to electrolysis. A large electric current is passed through the bath, causing the aluminum oxide to break down into aluminum metal and oxygen gas. The aluminum metal sinks to the bottom of the cell and is then tapped off and further processed. This process, known as the Hall-H茅roult process, is the predominant method for producing aluminum on an industrial scale.</p>

- Q: This question asks for typical applications of aluminum foil in everyday life.

- <p>Aluminum foil is commonly used for food storage, as it helps preserve freshness and prevents freezer burn. It's also used in cooking, either to cover dishes to retain moisture or to create packets for steaming or baking. In the kitchen, it's often used to line baking sheets to prevent food from sticking. Beyond cooking, aluminum foil is used for insulation, in arts and crafts, and even for cleaning purposes, such as buffing glass or polishing silverware. It's a versatile material found in many households and commercial settings.</p>

- Q: What are some safety measures that should be taken into account when working with aluminum?

- <p>When working with aluminum, it's important to follow several safety precautions. Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a dust mask to protect against aluminum dust. Ensure proper ventilation to avoid inhaling aluminum dust or fumes. Use spark-resistant tools when cutting or welding aluminum to minimize the risk of fire. Keep a fire extinguisher nearby and be aware of the flammability of aluminum. Store aluminum in a dry, cool place to prevent it from reacting with moisture. Lastly, be cautious when handling aluminum alloys, as some can be more reactive or hazardous than pure aluminum.</p>

Send your message to us

Aluminum 18 Gauge Flat Circle 1070/1060/1050 for Spinning, Pressing, Deep Drawing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords