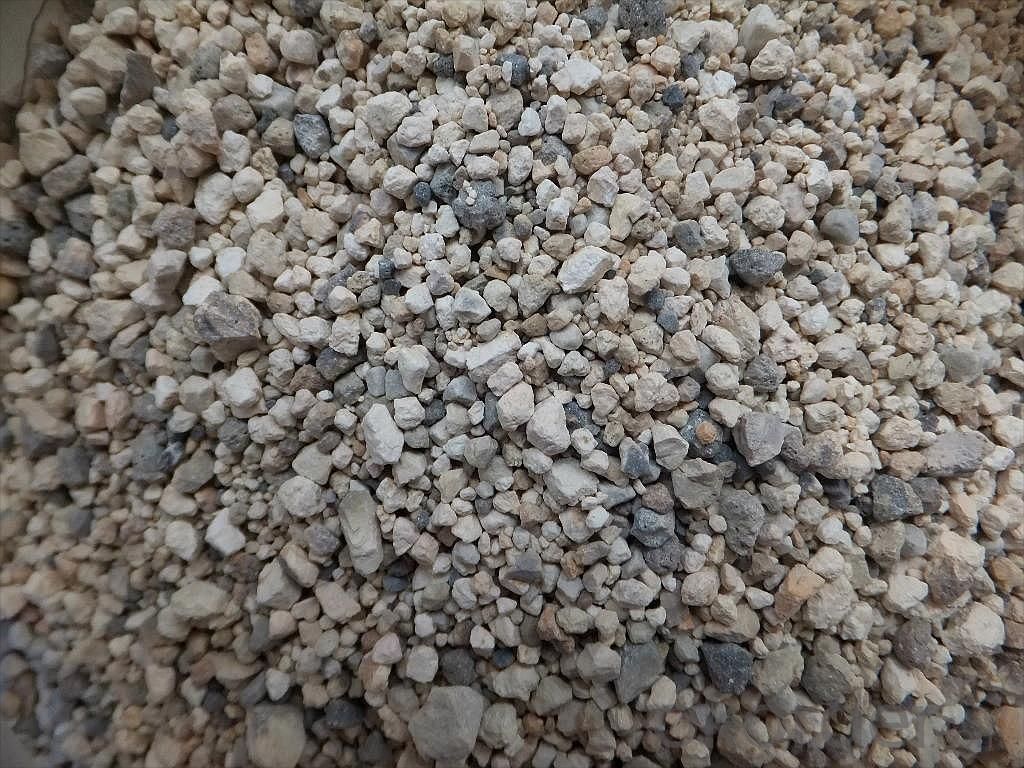

Raw Materials for Refractory:Rotary Kiln Alumina Calcined Bauxite 86 Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DESCRIPTION

QUIKE DETAILS

| Place of Origin: | Shanxi, China (Mainland) | Shape: | Block , Powder | Material: | Bauxite |

| SiO2 Content (%): | 8% Max | Al2O3 Content (%): | 86%Min | Fe2O3 Content (%): | 2%Max |

| CaO Content (%): | CaO+MgO<0.6 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | International standard |

| SiC Content (%): | International standard | Model Number: | Rotary Kiln Bauxite 86 | Brand Name: | CNBM |

PACKAGING & DELIVERY

| Packaging Details: | JUMBO BAGS/WOVEN BAGS/ PAPER BAGS (pallets) or as per customers' request! |

| Delivery Detail: | 25 days after buyer's instruction. |

SIZES

| GRAIN | normaly 0-1/1-3/3-5mm,or as per customers' request |

| POWDER | -200/-220/-325mesh,or as per customers' request |

OTHER GRADES OF RKB

GRADE | CHEMICAL CONTENT,% | PHYCICAL PROPERTIES | |||||

Al2O3,% | Fe2O3,% | TiO2,% | CaO+MgO,% | R2O,% | DENSITY, g/cm3 | WATER ABSORPTION,% | |

GAL-70 | ≥70 | ≤2.0 | - | ≤0.6 | ≤0.6 | ≥2.75 | ≤5.0 |

GAL-80 | ≥80 | ≤2.0 | ≤4.0 | ≤0.5 | ≤0.5 | ≥2.90 | ≤5.0 |

GAL-85 | ≥85 | ≤1.8 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.10 | ≤4.0 |

GAL-88 | ≥88 | ≤1.5 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.15 | ≤4.0 |

GAL-88HG | ≥88 | ≤1.5 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.25 | - |

PICTURES

COMPANY PROFILE

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

Since 2004, the trading volume of CNBM International has been doubled in 5 successive years owing to the support of superior corporations and effort of all staff. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target.

In line with the business, CNBM International launched E-business platform Okorder.com.

Our goal is to transform CNBM International into the global leading brand in building materials industry within 3 to 5 years through innovation and reform, by strengthening the overall management of supply chain, developing and cultivating both domestic and overseas market, improving the procedure and information system, enhancing the ability to organize resources and to provide value-added services under a professional team and a learning organization.

With the advantages in Cement, Composite Materials, New Building Materials and Engineering, we mainly concentrate on coal, steel and construction equipments and give priority to solar and wind energy development simultaneously utilizing our competitive position on traditional building materials to achieve sales revenue of RMB10 Billion in 2013.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: Can anyone tell me what material the first rate fire resistant door is?

- Material of Class A fire doors can be divided into steel and wood, so fire doors can be divided into fireproof steel door and fireproof wooden door. In fact, fire doors of all classes are divided into steel, wood, steel and wood, and other materials (see GB ). Mainly depending on what kind of material the customers want. The fire door is called class A fire door not because of the material but because of the fire-resistant time. The fire resistant time of class A fire door is not less than 1.2 hours and fire doors as long as meeting this condition can be called class A fire doors . The filling material in class A fire doors is generally perlite, whose difference is in thickness. A few of them will use fireproofing materials like foam core board, vermiculite fireproof board, MC composite material and so on. The thickness of class A fire door is usually 50mm. I hope my answer can help you.

- Q: For refractory, what is critical particle size? Thank you.

- For example, in refractory technology, if there is an express of equal to or lower than 0.008mm, 0.008 refers to critical particle size. The main criterion for judging performance of three major continuous casting is the major three normal temperature indexes (compressive strength and anti bending strength at normal temperature, apparent porosity and bulk density). Does this criterion have any defect? How to do multiple test if high-temperature index introduced? Carbon bond is one of the three major castings. How does it form? What do you think of it? Hope someone explains it for me. Thanks a lot!

- Q: What are the new refractories? What are the features? How about their application and development?

- In metallurgy, in what position should it be used, in order to make the best. Answers are as following. In iron, steelmaking or converter. When questioning, pay attention to the ways. Answers: Try to use synthetic refractory materials.

- Q: What is the use of refractory?

- Refractories mainly provide stable working environment for high temperature operation , such as metallurgical industry (steel ladle, hot-metal bottle, torpedo car and most places directly in contact with molten steel and iron), chemical industry (coke oven cokeing, dry quenching engineering) and building materials industry (lime kiln and glass kiln)

- Q: Which refractory quality inspection authority is good?

- National testing agencies include National Refractory Inspection Center (i.e. LIRR), China Building Materials Academy (Guanzhuang, Beijing), National Center for Ceramic and Refractory Materials Inspection (Shandong) and China Metallurgical Research Institute (Beijing).

- Q: What high-molecular polymers can be used as fire-resistant material binder?

- Lignin is the least expensive.

- Q: What is the magnesium carbon refractory?

- The composition of refractory brick There are many types of raw materials of refractory brick, mainly divided into six categories: Soil, stone, sand, mineral, power and others. The first kind of raw material, soil: Aluminum soil, kaolin, clay, diatomaceous earth The second kind of raw material, Stone: Fluorite, kyanite, andalusite, forsterite, vermiculite, mullite, pyrophyllite, chlorite, dolomite, sillimanite, magnesia-alumina spinel, silica The third kind of raw material, sand: Pottery, zircon sand, quartz sand, magnesite The fourth kind of raw material, ore: Chrome ore The fifth kind of raw material, powder: Aluminum powder, silica powder, silicon powder The sixth kind of raw material of refractory brick, others: Asphalt, graphite, phenolic resins, perlite, cenosphere, sialon, corundum, silicon sulfate, silicon carbide, sodium silicate, silica solution, boron carbide, calcium aluminate cement, nitride material, shale ceramisite, alumina, alumina sol and zirconia, etc.

- Q: What are the differences between first-level fire-resistant materials and second-level fire-resistant materials?

- The combustion performance of materials could be divided into: A( noninflammability), B1(flame retardancy), B2(flammability), B3(inflammability). Building materials are divided into four ranks according to these properties. 1. In accordance with Code for Design of Building Fire Protection(GBJ16-1987)(revised edition in 2001), fire hazards in producing and storage can be divided into five types. In Fire Prevention Code of Petrol Chemical Enterprise Design(GB50160--1992)(revised edition in 1999), classification of fire hazards is also achieved according to the hazards of materials that have been using, producing and storing. Measures in prevention of fire explosion could be taken from the perspectives of fire separation, fire resistance level of structures, allowable floors, safe evacuation, and fire extinguishing facilities based on different levels of fire hazards. 2. Four fire resistance rating of buildings are listed in the book Code for Design of Building Fire Protection. And specific stipulations are made to the fire resistance of main elements of buildings, such as bearing walls, beams,pillars, and floors. When designing a building, if permitted, refractory materials of high-rank should be adopted in those buildings which have high potential fire hazard and a lot of combustible material and valuable equipment. While making sure fire resistance rating, the duration of fire resistance of each elements should meet its requirements.

- Q: Who know about the knowledge of acid refractory material? Please explain in detail.

- Abrasion resistance of fire resistance material depends on the material group and structural material. The abrasion resistance of dense single crystal materials depends on the hardness of mineral crystal. The higher the hardness, the more resistance the material is to abrasion. non mineral crystals with fine grain material has a high wear resistance. The abrasion resistance of materials is related to bulk density or porosity. Aluminium refractory material can resist a temperature as high as 700~900 degree within the elastic range. The higher the temperature, the lower the resistance. Abrasion resistance will be increased with elastic modulus as temperature increase. In many cases, refractory material will often cause a lot of harm due to mechanical abrasion.

- Q: How many external wall thermal insulation fireproof material are there

- Inorganic active wall thermal insulation materials, cement foam thermal insulation board, glazed hollow bead insulation mortar, rock wool plate, glass wool plate etc., if used for external wall thermal insulation, rock wool board more frequently used.

Send your message to us

Raw Materials for Refractory:Rotary Kiln Alumina Calcined Bauxite 86 Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords