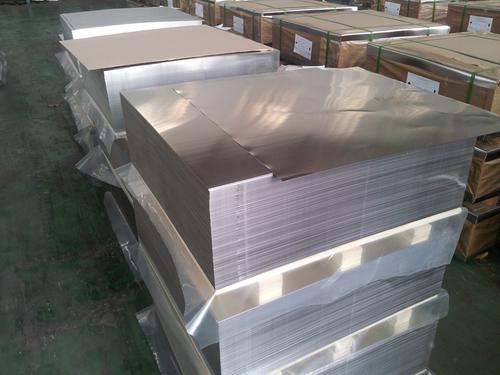

Quality Tinplate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Our Tinplates Specification is as below:

Standard: ISO 11949 -1995, JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width and Length: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Tincoating:customized

- Q: How is tinplate used in the pharmaceutical industry?

- Tinplate is commonly used in the pharmaceutical industry for packaging purposes. It is often utilized to create metal containers such as cans or tubes to store various types of medications, ointments, creams, or powders. Tinplate provides a durable and corrosion-resistant packaging solution that helps protect the pharmaceutical products from external factors like moisture, light, and air, ensuring their quality and extending their shelf life. Additionally, tinplate containers can be easily sealed to maintain product integrity and provide tamper-evident features, offering an added layer of safety for consumers.

- Q: How does tinplate compare to stainless steel in terms of properties and applications?

- Tinplate and stainless steel differ in terms of properties and applications. Tinplate is a steel sheet coated with a thin layer of tin, providing it with corrosion resistance and a shiny appearance. On the other hand, stainless steel is an alloy containing chromium, providing it with exceptional corrosion resistance and high strength. In terms of properties, stainless steel outperforms tinplate. Stainless steel offers superior corrosion resistance, even in harsh environments, making it suitable for applications where durability is crucial. It also has excellent heat resistance and can withstand high temperatures. Tinplate, although corrosion-resistant, is less durable and has a lower melting point. Regarding applications, tinplate is commonly used for food packaging, beverage cans, and other consumer products due to its excellent ability to preserve and protect the contents. The tin layer prevents the steel from coming into contact with the packaged goods, ensuring their safety and extending shelf life. Stainless steel, on the other hand, finds extensive use in industries such as construction, automotive, medical, and kitchen appliances. Its strength, corrosion resistance, and hygienic properties make it ideal for structural components, surgical instruments, cutlery, and more. Overall, while tinplate is favored for its cost-effectiveness and specific packaging applications, stainless steel offers superior properties and versatility, making it suitable for a wide range of demanding industrial and domestic applications.

- Q: How does tinplate contribute to the durability of construction materials?

- Tinplate contributes to the durability of construction materials by providing a protective coating that helps prevent corrosion and rusting. This coating acts as a barrier against moisture and other environmental factors, extending the lifespan of the construction materials. Additionally, tinplate enhances the strength and structural integrity of the materials, making them more resistant to wear and tear.

- Q: How does tinplate contribute to sustainability efforts?

- Tinplate contributes to sustainability efforts by being a highly recyclable material. It can be used repeatedly without losing its properties, reducing the need for new resource extraction. Additionally, tinplate is commonly used for food and beverage packaging, which helps preserve products and reduces food waste. Its durability and corrosion resistance also extend the lifespan of products, making it a sustainable choice for various industries.

- Q: Can tinplate be used for outdoor applications?

- Yes, tinplate can be used for outdoor applications. Tinplate is a durable material that offers excellent resistance to corrosion, making it suitable for outdoor use. It is commonly used in the construction of outdoor signage, containers, and packaging materials.

- Q: How does tinplate compare to plastic packaging in terms of sustainability?

- Tinplate packaging generally has a higher sustainability profile compared to plastic packaging. Tinplate is a recyclable material that can be reused multiple times without losing its properties. It has a low carbon footprint, as it requires less energy to produce compared to plastic. Additionally, tinplate can be easily separated from other waste during recycling processes, making it more efficient for recycling systems. On the other hand, plastic packaging often ends up in landfills or as litter, taking hundreds of years to decompose and causing environmental harm. However, it is important to note that the sustainability of tinplate packaging also depends on factors like the energy source used during production and recycling rates in a particular region.

- Q: How is tinplate used in the production of aerosol valves?

- Tinplate is used in the production of aerosol valves as it provides a protective and corrosion-resistant coating to the valve components. This prevents the valve from rusting or reacting with the contents of the aerosol, ensuring the reliable and safe functioning of the aerosol valve.

- Q: What are the main export markets for tinplate?

- The main export markets for tinplate include countries such as China, Japan, South Korea, United States, and Germany.

- Q: How is tinplate coated for gift packaging?

- Tinplate is typically coated for gift packaging using a process called electroplating, where a thin layer of tin is applied to the surface of the tinplate. This coating not only enhances the appearance of the packaging but also provides protection against corrosion and oxidation.

- Q: How is tinplate coated for beverage cans?

- Tinplate is coated for beverage cans through a process called electrolytic tinplating. In this process, a thin layer of tin is electroplated onto the surface of the steel sheet. The steel sheet is first cleaned and then passed through an electrolyte solution containing tin salts. An electric current is then applied, causing tin ions to be reduced and deposited onto the steel surface, forming a protective and corrosion-resistant tin coating. This tin coating ensures that the beverage cans remain safe and free from any metallic taste.

Send your message to us

Quality Tinplate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords