Quality of Tin Free Steel TFS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

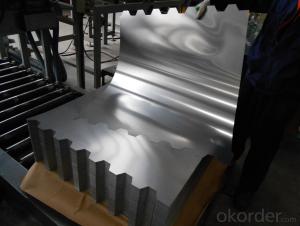

Tin Free Steel (TFS)

Is also known as chromed steel, as it is obtained by coating the metal base (low-carbon steel) with an ultra-thin layer of metallic chrome and then with a chromium oxide layer.This steel product was developed to meet economic requirements, and excels tinplate in paintability, paint adhesion, and economy. It is widely used for making beverage cans and 18-liter cans. It is also used for making photographic film cases and as a protective material for optical fiber cables.

Our TFS Specification:

Standard: AISI, ASTM, BS, DIN, GB, JIS

Material: MR,SPCC

Thickness:0.15mm - 0.45mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Oil: DOS

Surface: Finish,bright,stone,matte,silver

Packing:

1、For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

2、For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

Both Prime and Second Quality Are Available!!!

- Q: How does tinplate contribute to the overall portability of packaging?

- Tinplate contributes to the overall portability of packaging due to its lightweight nature and high strength-to-weight ratio. It allows for the creation of sturdy, yet lightweight packaging solutions, making it easier to handle, transport, and carry products.

- Q: Why do tin tins rust easily when they are opened?

- It turned out to be sealed and oxygen has been transpiring. When opening is oxidized (Fe2o3), there is rust.

- Q: What are the typical finishing options for tinplate products?

- The typical finishing options for tinplate products include painting, printing, coating, embossing, and varnishing. These options not only enhance the appearance of the tinplate products but also provide protection against corrosion and improve overall durability.

- Q: What are the common sizes and shapes of tinplate products?

- Common sizes and shapes of tinplate products include rectangular or square containers, cylindrical cans, and tinplate sheets or strips in various dimensions. These sizes and shapes are commonly used for packaging food, beverages, cosmetics, and other consumer goods.

- Q: Can tinplate be used for signage?

- Yes, tinplate can be used for signage. It is a durable and versatile material that can be easily shaped, painted, and printed on, making it suitable for creating various types of signs. Additionally, tinplate is corrosion-resistant, which ensures the longevity of the signage, even when exposed to outdoor elements.

- Q: Cookies with tinplate packaging has what advantage?

- The decoration is exquisite: the metal material has good printing performance; the design trademark is bright and beautiful; the packaging container made by it is noticeable, and it is a kind of good sale packing.

- Q: How does tinplate compare to plastic-coated steel in terms of properties and applications?

- Tinplate and plastic-coated steel differ in terms of properties and applications. Tinplate offers excellent corrosion resistance and can be easily soldered, making it suitable for food and beverage packaging, aerosol cans, and decorative items. On the other hand, plastic-coated steel provides enhanced durability, impact resistance, and chemical resistance, making it ideal for automotive parts, electrical enclosures, and construction applications. Ultimately, the choice between the two depends on the specific requirements of the intended application.

- Q: Can tinplate be used for construction applications?

- Yes, tinplate can be used for construction applications. It is often utilized for roofing, siding, ceilings, and other structural components due to its durability, corrosion resistance, and lightweight properties.

- Q: Can tinplate be used for aerosol packaging?

- Yes, tinplate can be used for aerosol packaging.

- Q: How has tinplate evolved over the years?

- Tinplate has evolved significantly over the years in terms of its production process, durability, and applications. Initially, tinplate was made by coating iron sheets with a thin layer of tin to prevent corrosion. However, as technology advanced, electroplating replaced the traditional hot-dipping method, resulting in a more efficient and cost-effective production process. Additionally, the development of various alloy coatings has further enhanced the durability of tinplate, making it more resistant to rust and damage. Moreover, tinplate has expanded its applications beyond traditional cans, finding its way into packaging for food, beverages, aerosols, and cosmetics. Overall, the evolution of tinplate has revolutionized the packaging industry, offering improved quality, versatility, and sustainability.

Send your message to us

Quality of Tin Free Steel TFS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords