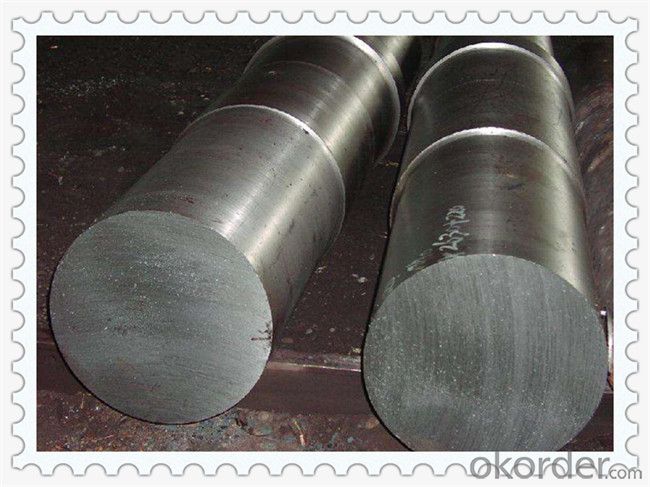

Q235 Hot Rolled Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

SS490 hot rolled carbon steel round bar

Dimensions: 15-300mm

Near the seaport, low cost, quick delivery

SGS BV inspection, Good reputation &service

Product name | SS490 hot rolled carbon steel round bar |

Dimensions | 15-300mm |

Length | 4-12m |

Standard | ASTM,BS,GB,JIS |

Other Grade | Q215,Q235,HPB300,SS330-SS490,A36,SAE1015-1020,S235JR,S275JR,ST37-2,etc |

Brand | RGTS |

Application | Mild Steel Round Bar is used for making security grills, screens, Construction and Machine Manufacture. |

Finish condition | hot rolled |

Appearance | new |

Sales mode | factory direct sales |

Quality assurance | mill test certificate is provided, third party inspection is acceptable |

Trade term | FOB/CIF/CFR |

Payment term | 30%T/T in advance, balance against B/L copy;Sight irrevocable LC |

Delivery time | Within 15-30 days after receiving original LC or deposit, also according to the quantity |

Loading port | Xingang tianjin, China |

Certification | ISO9001:2000/BV |

SS490 hot rolled carbon steel round bar details

Size Tolerance: +/-5mm

Length tolerance: +100mm/-0mm

Side length tolerance: +/-2mm

Straightness:Max 6mm/m

Both end of each bar must be cut

Ladle furnaced and vacuum de-gassed

Show heat No. on each bar

SS490 hot rolled carbon steel round bar

Chemical Composition:

P% ≤0.050

S% ≤0.050

Cr% ≤0.20

Physical Property (MPa):

Y/S: ≥285

T/S: 490~610

- Q: Can steel round bars be plated with other metals?

- Steel round bars can indeed be plated with other metals, a process known as plating. Plating involves applying a thin layer of one metal onto the surface of another metal. This is commonly done to enhance the appearance of the steel round bar or to provide it with additional properties like corrosion resistance or improved conductivity. To plate the steel round bar, it is immersed in a solution containing ions of the desired metal. These metal ions are then deposited onto the surface of the steel through the use of electrical currents or chemical reactions, resulting in a thin and even coating. Nickel, chrome, zinc, and copper are among the popular metals used for plating steel round bars. Plating is a versatile and cost-effective technique for enhancing the performance and aesthetics of steel round bars in various applications.

- Q: Are steel round bars suitable for use in the manufacturing of springs?

- Yes, steel round bars are suitable for use in the manufacturing of springs. Steel round bars offer excellent strength, durability, and elasticity, which are crucial characteristics for springs. Additionally, steel round bars can be easily machined, formed, and heat-treated to achieve the desired properties for specific spring applications.

- Q: What are the properties of steel round bars?

- Steel round bars are widely used in various industries due to their numerous properties. Firstly, their strength and durability are highly recognized. Steel is known for its exceptional strength, which is retained in the round bar form. This makes steel round bars perfect for applications requiring high strength and toughness, such as construction, manufacturing, and engineering. Secondly, steel round bars possess excellent machinability. They can be easily cut, drilled, and shaped, making them adaptable for various projects. This characteristic allows for effortless fabrication and customization of the round bars to meet specific requirements. Moreover, steel round bars exhibit good corrosion resistance. They are often made from stainless steel or alloyed steel, enhancing their resistance to rust and other forms of corrosion. Consequently, they can be utilized in outdoor and harsh environments, where exposure to moisture and chemicals can potentially damage other materials. Another significant property of steel round bars is their exceptional thermal and electrical conductivity. This makes them suitable for applications that require efficient heat or electricity conduction, such as electrical systems or heat exchangers. Furthermore, steel round bars have a sleek and polished surface finish. This not only enhances their aesthetics but also improves their resistance to wear and tear. The smooth surface reduces friction and allows for easy movement or rotation, making steel round bars ideal for use in mechanical components and machinery. Lastly, steel round bars are available in a wide range of sizes, grades, and finishes. This provides flexibility in application and ensures the selection of the appropriate round bar based on specific requirements. In conclusion, the versatile and reliable nature of steel round bars, characterized by their strength, machinability, corrosion resistance, thermal and electrical conductivity, surface finish, and availability in various sizes and grades, make them a favored choice for numerous industrial applications.

- Q: 40CrMo what is the round steel material?

- Requirements for the manufacture of 35CrMo steel with higher strength and conditioning section large forgings, such as locomotive traction gears, with supercharger drive gear, the rear axle, the connecting rod and the spring load greatly clip, 2000m can also be used for the following deep oil drill pipe joints and fishing tools etc..

- Q: What are the safety precautions when handling steel round bars?

- When handling steel round bars, it is important to follow certain safety precautions. These include wearing appropriate personal protective equipment such as safety gloves, goggles, and steel-toed boots to protect against potential injuries. Additionally, workers should be trained on the correct lifting techniques to avoid strains or back injuries. It is crucial to inspect the bars for any defects or damages before handling them, as flawed bars can pose safety risks. Proper storage and handling techniques should be followed to prevent accidents such as tripping or falling. Lastly, communication and coordination among workers are essential to ensure a safe working environment when handling steel round bars.

- Q: What's the difference between round steel and carbon bound steel?

- Shape is different, round steel round appearance, no grain without ribs, carbon steel surface has engraved or ribbed, so that the round bar and concrete bonding force is small, carbon tie steel and concrete bonding force.

- Q: Can steel round bars be used for making steering components?

- Indeed, it is possible to utilize steel round bars in the production of steering components. The utilization of steel as a material for steering system components is quite prevalent owing to its remarkable strength and resilience. By machining or forging steel round bars, one can fashion them into diverse shapes and sizes to fabricate steering components like steering shafts, tie rods, and drag links. These components necessitate the capability to endure the forces and pressures exerted upon them during steering, and steel's properties render it suitable for this purpose. Moreover, steel is effortlessly obtainable and cost-efficient, rendering it a favored option for the production of steering components in numerous sectors, including automotive and aerospace.

- Q: 4145H round steel is equivalent to the domestic brand?

- 42CrMo steel is ultra high strength steel, high strength and toughness, hardenability is also good, no obvious temper brittleness, after quenching and tempering treatment have high fatigue limit and anti shocksand low temperature impact toughness. The steel is suitable for making large and medium plastic moulds with certain strength and toughness.

- Q: How are steel round bars used in the construction of pipelines?

- Steel round bars are commonly used in the construction of pipelines due to their high strength and durability. These bars are typically made from carbon or alloy steel and are available in various sizes and grades to suit the specific requirements of the pipeline. One of the key uses of steel round bars in pipeline construction is for reinforcement. They are often used as reinforcement in concrete foundations and supports along the pipeline route. The bars provide added strength and stability to the structure, ensuring that the pipeline remains secure and can withstand external forces such as soil movement or seismic activity. Additionally, steel round bars are also used as the main material for the fabrication of pipeline joints. These bars are typically bent or welded to form various shapes and sizes to connect different sections of the pipeline. The high tensile strength of steel ensures that the joints can withstand the pressure and stress exerted by the fluids being transported through the pipeline. Moreover, steel round bars are utilized in the construction of pipeline hangers and supports. These bars are often shaped and welded to form brackets or clamps that hold the pipeline in place. The bars provide a sturdy and reliable support system, preventing sagging or movement of the pipeline, and ensuring smooth and uninterrupted flow. In summary, steel round bars play a crucial role in the construction of pipelines. They are used for reinforcement, fabrication of pipeline joints, and the construction of hangers and supports. Their high strength, durability, and versatility make them an ideal choice for ensuring the structural integrity and reliability of pipelines.

- Q: How are steel round bars used in the oil and gas industry?

- Steel round bars are commonly used in the oil and gas industry for various applications. They are utilized in the construction of drilling equipment, such as drill bits and drill collars, as well as in the manufacturing of valves, pipelines, and other components that need to withstand high pressure and corrosion. The strength and durability of steel round bars make them ideal for withstanding the harsh operating conditions encountered in the oil and gas sector.

Send your message to us

Q235 Hot Rolled Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords