Q235 Stainless high quality steel round bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Q235 Stainless high quality steel round bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Q235 Stainless high quality steel round bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Q235 Stainless high quality steel round bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

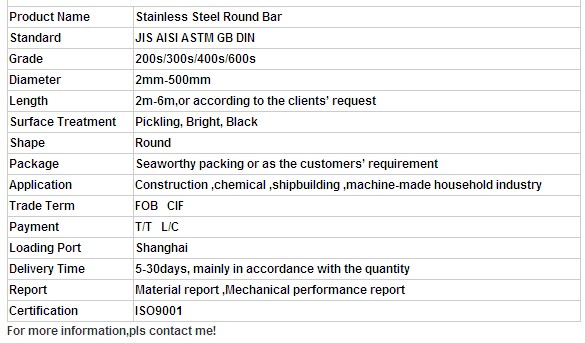

Product Specifications:

stainless steel round bar

1.Specification:12-300mm

2.Material:304 316

3.Length:standard 6m

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q: Are steel round bars available in metric sizes?

- Metric sizes of steel round bars are indeed available. Many manufacturers and suppliers cater to customers who utilize the metric system by offering steel round bars in addition to the standard imperial sizes. These metric measurements are commonly utilized in countries that adhere to the metric system as their primary unit of measurement. They provide a diverse selection of metric diameters and lengths suitable for various applications and industries. To ensure the availability of steel round bars in the desired metric sizes, it is advisable to verify with the specific supplier or manufacturer.

- Q: What is the difference between hot rolled and cold drawn steel round bars?

- Hot rolled steel round bars are produced by heating a steel billet or ingot at a high temperature and then rolling it into the desired shape. This process results in a rougher surface finish and a larger diameter tolerance compared to cold drawn steel round bars. Hot rolled bars are commonly used in applications where strength and durability are important, such as in construction and manufacturing. On the other hand, cold drawn steel round bars are produced by pulling a hot rolled bar through a die at room temperature, which results in a smoother surface finish and tighter diameter tolerances. This process also improves the mechanical properties of the steel, such as its strength and hardness. Cold drawn bars are often used in applications where precision and a high-quality surface finish are required, such as in the production of shafts, bolts, and precision components. In summary, the main differences between hot rolled and cold drawn steel round bars are the surface finish, diameter tolerance, and mechanical properties. Hot rolled bars have a rougher surface finish, larger diameter tolerances, and are typically used in applications where strength and durability are important. Cold drawn bars have a smoother surface finish, tighter diameter tolerances, and are commonly used in applications where precision and a high-quality surface finish are required.

- Q: What are the typical hardness values for different grades of steel round bars?

- The typical hardness values for different grades of steel round bars can vary depending on the specific grade and manufacturing process. However, common ranges for hardness values in steel round bars can be between 200 and 400 on the Brinell hardness scale.

- Q: What are the different types of steel round bar surface finishes used in the construction industry?

- In the construction industry, steel round bars are commonly used for various applications due to their strength and durability. These steel round bars typically undergo different surface finishes to meet specific requirements and enhance their performance. Some of the common types of steel round bar surface finishes used in the construction industry include: 1. Hot Rolled Finish: This is the most basic and commonly used surface finish. It is achieved by heating the steel bar above its recrystallization temperature and then rolling it through a series of rollers. This process results in a rough and scale-covered surface. 2. Cold Drawn Finish: In this process, the steel round bar is drawn through a series of dies to reduce its diameter and increase its length. Cold drawing produces a smooth and shiny surface finish, which is ideal for applications where aesthetics and precision are important. 3. Peeled and Polished Finish: This surface finish involves removing the outer layer of the steel round bar using a peeling process. After peeling, the bar is polished to achieve a smooth and mirror-like surface. Peeled and polished finishes are often used in applications where a high level of visual appeal is desired, such as architectural structures or decorative elements. 4. Ground Finish: Grinding is used to achieve a smooth and uniform surface finish on steel round bars. The grinding process removes any imperfections or unevenness, resulting in a precise and polished surface. Ground finishes are commonly used in applications that require tight tolerances, such as machinery or automotive components. 5. Coated Finish: Steel round bars can also be coated with various materials to enhance their resistance to corrosion or provide additional properties. Common coating finishes include galvanized, epoxy, or powder coatings. These coatings not only protect the steel from environmental factors but also improve its aesthetic appeal. Each surface finish has its own advantages and is chosen based on the specific requirements of the construction project. Whether it is the need for improved aesthetics, enhanced corrosion resistance, or tighter tolerances, choosing the right surface finish is crucial to ensure the steel round bars perform optimally in their intended application.

- Q: Can steel round bars be used in the hospitality industry?

- Yes, steel round bars can be used in the hospitality industry. Steel round bars are versatile and durable, making them suitable for various applications within the industry. They can be used for constructing furniture, such as chairs, tables, and bar stools, as well as for creating decorative elements like railings, light fixtures, and signage. Steel round bars also provide excellent strength and stability, ensuring the safety of guests and staff. Moreover, they can be easily customized to match the desired aesthetic and design preferences of different hospitality establishments. Overall, steel round bars are a reliable and practical choice for the hospitality industry due to their durability, versatility, and aesthetic appeal.

- Q: Can steel round bars be used in the production of construction equipment?

- Yes, steel round bars can be used in the production of construction equipment. Steel round bars are commonly used in the construction industry for various applications, including the manufacturing of heavy machinery, equipment components, structural frames, and supports. The high strength and durability of steel make it an ideal material for constructing robust and reliable construction equipment.

- Q: What are the factors to consider when selecting a steel round bar?

- When selecting a steel round bar, there are several factors that should be taken into consideration. Firstly, it is important to consider the grade of steel. Different grades of steel have varying properties and strengths, so the specific application and requirements should be evaluated. For example, if high corrosion resistance is needed, stainless steel grades like 304 or 316 may be suitable, whereas for structural applications, carbon steel grades like A36 or 1018 may be more appropriate. Secondly, the dimensions and size of the round bar should be considered. This includes the diameter, length, and tolerance requirements. The size should be chosen based on the specific application, load-bearing capacity, and the available space for installation. Thirdly, the surface finish and condition of the round bar should be assessed. This includes factors such as surface roughness, straightness, and any surface defects. The surface finish should be selected based on the desired aesthetics, functional requirements, and the manufacturing process. Another important factor is the availability and cost of the steel round bar. It is crucial to consider the availability of the desired grade and size from suppliers, as well as the associated cost. It is advisable to compare prices from different suppliers to ensure the best value for money. Furthermore, the required mechanical properties of the steel round bar should be evaluated. This includes factors such as tensile strength, yield strength, hardness, and ductility. The mechanical properties should align with the intended application and load-bearing requirements. Lastly, it is essential to consider any additional requirements or certifications that may be needed. This could include compliance with specific industry standards (e.g., ASTM, ISO), certifications (e.g., RoHS, REACH), or specific testing requirements (e.g., ultrasonic testing, impact testing). In conclusion, when selecting a steel round bar, it is important to consider the grade, dimensions, surface finish, availability, cost, mechanical properties, and any additional requirements. Taking into account these factors will help ensure that the steel round bar chosen is suitable for the intended application and meets all necessary specifications.

- Q: How do you calculate the fatigue strength of a steel round bar?

- To calculate the fatigue strength of a steel round bar, you typically conduct a fatigue test, also known as a fatigue life assessment. This involves subjecting the round bar to repeated loading cycles, with varying stress levels, until it fails. The number of cycles the bar can withstand before failure is the fatigue strength. This test helps determine the endurance limit or fatigue limit of the steel round bar, which represents the maximum stress level that the bar can endure indefinitely without failure.

- Q: Are steel round bars suitable for food processing applications?

- Due to its numerous desirable properties, steel round bars are widely utilized in food processing applications. The durability of steel allows it to withstand heavy usage and frequent cleaning in food processing environments, making it an excellent choice for equipment like conveyor belts, mixers, and cutting tools. Moreover, steel round bars exhibit resistance to corrosion, a crucial characteristic for food processing applications that often involve exposure to moisture and various chemicals. This resistance ensures that the equipment remains hygienic and safe for food production. Additionally, steel round bars can be easily machined and fabricated into different shapes and sizes, making them highly versatile for fulfilling various food processing needs. They can be utilized to create custom equipment or components that meet specific requirements, thereby ensuring efficient and effective food processing operations. Furthermore, steel proves to be a cost-effective material for food processing applications. It offers remarkable value for money, delivering long-lasting performance, requiring minimal maintenance, and being readily available in the market. Nevertheless, it is important to note that not all steel round bars are suitable for food processing applications. In this industry, stainless steel is the most commonly used type of steel due to its enhanced corrosion resistance and hygienic properties. Consequently, when selecting steel round bars for food processing applications, it is crucial to ensure that they conform to the necessary standards and regulations for food safety.

- Q: How can steel round bars be protected from corrosion?

- Steel round bars can be protected from corrosion through various methods. One of the most common ways is by applying a protective coating such as paint or enamel. This coating acts as a barrier between the steel and the corrosive elements in the environment, preventing direct contact and reducing the chances of corrosion. Another effective method is through the use of galvanization. This involves coating the steel round bars with a layer of zinc. Zinc is a sacrificial metal, which means it corrodes more easily than steel. So, when the round bars are exposed to moisture or other corrosive substances, the zinc coating will corrode instead of the steel, providing an added layer of protection. Using stainless steel round bars is also a great way to prevent corrosion. Stainless steel contains a significant amount of chromium, which forms a passive layer on the surface of the steel. This passive layer acts as a shield, protecting the steel from corrosion caused by moisture or other corrosive agents. Regular maintenance and cleaning of the steel round bars is crucial in preventing corrosion. Removing dirt, dust, and other contaminants from the surface helps to maintain the protective coating or passive layer, if present. Additionally, keeping the round bars dry and storing them in a well-ventilated area can also help prevent corrosion. Lastly, proper handling and storage of steel round bars are important. They should be stored in a dry and covered area to prevent exposure to moisture and corrosive elements. Avoiding contact with other metals or materials that can cause galvanic corrosion is also essential. By implementing these protective measures, steel round bars can be effectively shielded from corrosion, ensuring their longevity and structural integrity.

Send your message to us

Q235 Stainless high quality steel round bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords