PVC Waterproofing Menbrane for Roofing Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Waterproofing Menbrane for Roofing Construction

Product Description of PVC Waterproofing Menbrane for Roofing Construction:

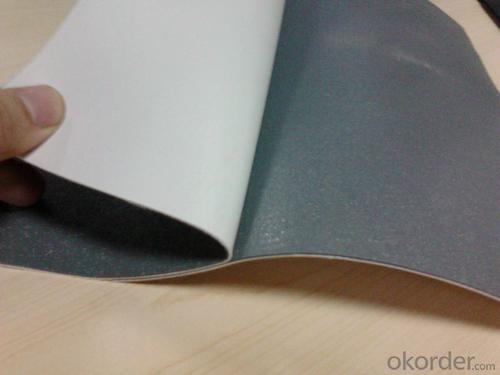

PVC Membrane Waterproof /Waterproofing membrane For Roof is a new polymer waterproof membrane. The PVC Membrane Waterproof /Waterproofing membrane For Roof raw material is polyvinyl chloride resin, mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Thickness: 1.2mm/1.5mm/1.8mm/2.0mm

Width:2050mm

Length:20m( Special specifications can be customized)

Size: 2.05mx20m

Color: white/grey, or any other colors.

Features of PVC PVC Waterproofing Menbrane for Roofing Construction:

1. Excellent anti-aging property.

2. Puncture- resistant.

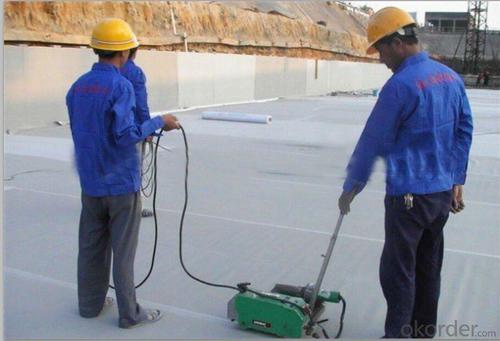

3. Welding construction,

4. High tensile strength, good elongation, good dimensional stability.

5. Good plasticity.

6. It has self-extinguishing from fire property.

7. Materials surface is smooth, fast color, stain resistance.

8. More wide, Wastage become less when being used.

Classification of PVC Waterproofing Menbrane for Roofing Construction:

1. N: Homogeneous PVC membrane

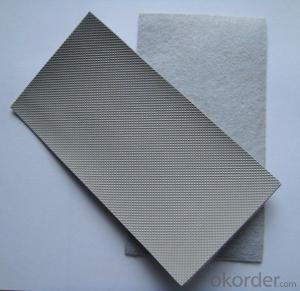

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Waterproofing Menbrane for Roofing Construction:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproofing Menbrane for Roofing Construction:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Waterproof Membrane in 1.2mm Thickness:

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

Images of PVC Waterproofing Menbrane for Roofing Construction:

FAQ:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used on breeze block surfaces?

- Yes, a waterproofing membrane can be used on breeze block surfaces. Breeze blocks, also known as concrete blocks, are commonly used in construction and have a porous nature. This allows water to seep through the blocks, potentially causing dampness or water damage in the building. To prevent this, a waterproofing membrane can be applied to the surface of the breeze blocks. A waterproofing membrane is a thin layer of material that is designed to prevent water penetration. It acts as a barrier, preventing water from seeping into the breeze blocks and protecting the underlying structure from moisture damage. The membrane is typically applied in liquid or sheet form and is adhered to the surface of the breeze blocks using an appropriate adhesive. Before applying a waterproofing membrane, it is important to properly prepare the breeze block surface. This may involve cleaning the surface and ensuring it is free from any loose debris or contaminants. Additionally, any cracks or gaps in the breeze blocks should be repaired prior to applying the membrane to ensure a seamless and effective waterproofing system. It is worth noting that the type of waterproofing membrane used will depend on the specific requirements of the project and the conditions the breeze block surface will be exposed to. There are various types of waterproofing membranes available, such as liquid-applied membranes, sheet membranes, or cementitious coatings. It is recommended to consult with a professional or manufacturer to determine the most suitable waterproofing membrane for your specific application. In conclusion, a waterproofing membrane can be used on breeze block surfaces to effectively prevent water penetration and protect the underlying structure from moisture damage. Proper preparation of the surface and selection of the appropriate membrane type are important factors to ensure a successful waterproofing solution.

- Q: Are waterproofing membranes resistant to impact damage?

- Waterproofing membranes offer protection against water infiltration and typically resist impact damage to varying degrees. The level of impact resistance depends on the specific membrane type and quality. Generally, high-quality waterproofing membranes are designed to endure normal impacts and stresses that occur during installation and use. They are manufactured using durable materials, like modified bitumen, rubberized asphalt, or synthetic polymers, which enhance their strength and resilience. Although waterproofing membranes can withstand minor impact damage, they are not completely impervious to more significant impacts. Dropping heavy objects or sharp objects falling onto the membrane can potentially cause punctures or tears, compromising the integrity of the waterproofing system. This can result in water infiltration and potential structural issues. To enhance impact resistance, additional protective measures can be taken, such as installing a protective layer or using reinforced membranes. These extra layers or reinforcements provide an additional barrier against impact damage, ensuring the long-term performance and durability of the waterproofing system. In conclusion, while waterproofing membranes generally resist impact damage, it is crucial to handle them with care during installation and avoid unnecessary impacts that could potentially compromise their integrity.

- Q: Does a waterproofing membrane require a primer before application?

- Yes, a waterproofing membrane usually requires a primer before application. The primer helps to improve adhesion between the membrane and the substrate, ensuring a strong and durable bond. It also helps to seal the surface, preventing any moisture or contaminants from interfering with the membrane's performance. Applying a primer before the membrane ensures better effectiveness and longevity of the waterproofing system.

- Q: Can waterproofing membranes be used on roofs with slopes?

- Yes, waterproofing membranes can be used on roofs with slopes. These membranes are designed to provide a protective barrier against water infiltration and are commonly used on roofs with varying degrees of slope to prevent leaks and water damage.

- Q: Can waterproofing membranes be installed on uneven surfaces?

- Yes, waterproofing membranes can be installed on uneven surfaces. However, to ensure effective installation, it is important to properly prepare the surface by leveling or smoothing it out as much as possible before applying the membrane.

- Q: Are waterproofing membranes resistant to acid rain?

- Yes, waterproofing membranes are generally resistant to acid rain due to their ability to protect against water penetration and chemical exposure.

- Q: Can a waterproofing membrane be used on tile surfaces?

- Yes, a waterproofing membrane can be used on tile surfaces. A waterproofing membrane is a thin layer of material that is designed to prevent water or moisture from penetrating through to the underlying surface. It is commonly used in areas where water exposure is high, such as bathrooms, showers, or outdoor areas. When applied properly, a waterproofing membrane can create a barrier that protects the tile surface from water damage, preventing issues such as mold, mildew, or tile deterioration. It is important to ensure that the waterproofing membrane is compatible with the type of tile being used and that it is installed correctly to ensure maximum effectiveness.

- Q: Can a waterproofing membrane be applied to concrete surfaces?

- Yes, a waterproofing membrane can be applied to concrete surfaces. Waterproofing membranes are designed to create a barrier against water penetration, and they can be used on a variety of surfaces, including concrete. The membrane is typically applied to the surface of the concrete using a brush, roller, or spray application method. It forms a protective layer that prevents water from seeping through the concrete and causing damage. This is particularly important in areas where water exposure is high, such as basements, swimming pools, or outdoor concrete surfaces. By applying a waterproofing membrane, you can greatly enhance the durability and longevity of the concrete surface while also protecting it from moisture-related issues such as cracks, mold, or degradation.

- Q: Are waterproofing membranes resistant to ponding water?

- Yes, waterproofing membranes are designed to be resistant to ponding water. These membranes create a barrier that prevents water from seeping through and causing damage to the underlying structure.

- Q: What is the best waterproofing membrane for my project?

- The choice of the best waterproofing membrane for your project will depend on various factors, such as the project type, specific requirements, and budget. There are multiple options available in the market, each offering unique features and advantages. One favored option is the bituminous waterproofing membrane, which is cost-effective and suitable for a wide range of projects like roofs, basements, and foundations. These membranes are durable, flexible, and can withstand extreme weather conditions. They can be applied using methods like torch-on, self-adhesive, or hot-melt. Another alternative to consider is the polyurethane liquid membrane, which provides exceptional elasticity and is ideal for areas requiring flexibility, such as balconies, terraces, and swimming pools. These membranes are resistant to UV rays and can be easily applied using a brush or roller. For projects that demand high durability and resistance, the cementitious waterproofing membrane might be the optimal choice. This type of membrane is a mixture of cement, sand, and special additives that create a thick and protective layer. It is commonly used for underground structures, tunnels, and water tanks. If your project involves below-grade applications or areas with high water pressure, the bentonite waterproofing membrane could be the most suitable option. Bentonite membranes, made of clay minerals, swell when exposed to water, forming a watertight barrier. They are commonly used in basements, foundations, and retaining walls. Ultimately, determining the best waterproofing membrane for your project will depend on your specific requirements, budget, and preferences. It is advisable to consult with a professional waterproofing contractor who can assess your project's needs and recommend the most suitable membrane system.

Send your message to us

PVC Waterproofing Menbrane for Roofing Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords