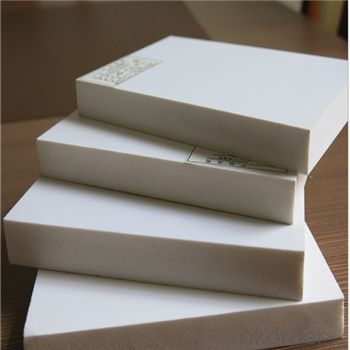

PVC Foam Sheet lowes polycarbonate panels roofing sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1. Brief Introduction

There are two kinds of PVC Sheet: PVC Foam Sheet and PVC Rigid sheet, and each of them could be cataloged by different producing processes.

They could be used in furniture making such as bathroom and kitchen cabinet or wall cladding , advertising field such as sign board, printing board, indusry field such as the cushion for the heavy machine, etc.

2. Application

1) Advertising Signs, billboards, displays, exhibition stands |

2) Screen printing, laser engraving |

3) Thermoformed parts |

4) Architecture, indoor and outdoor decoration |

5) Furniture, kitchen & bathroom cabinet |

6) Walls & partitions, wall cladding |

7) Ceiling boards |

8) Poolside furniture, swimming pool floor planking |

9) Chemical industry and laboratory equipment |

10) Apparatus, container & machine construction |

11) Interior scaleboard for boat & ship, vehicle, train |

3. PVC Foam Board Feature:

1. waterproof, fire retardant, acid and alkali, moth, light, heat, noise, vibration characteristics;

2. equal and wood processing, and processing performance is far superior to wood;

3. wood, aluminum, composite board ideal alternative;

4. crust plate surface is very smooth, high hardness, not easy scratches, commonly used in the production of cabinets, furniture;

4.Pictures:

4.FAQ

Q If the products have some quality problem ,how will you deal with it?

A: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Q: Could you provide samples?

A : Yes, We provide free samples for customers, but customer shall bear the freight charges or negotiate about this.

- Q: Decoration commonly used plate brand?

- Plate top ten brands of Moganshan Sublimation Yunfeng was founded in 1995, after more than 10 years of struggle and hard work, the achievements of today - China's largest and most influential environmental protection decorative materials production enterprises. The company's own "Moganshan" brand has become China's first brand of environmental protection sheet, the Chinese famous brand, well-known trademarks in China. Top 10 brands of gold plate JINQIU Hebei Jinqiu Wood Co., Ltd. was founded in 1984, the autumn JINQIU is its brand, the company is a collection of sheet production, sales and after-sales service as one of the enterprises, the main products are sheet, particleboard, decorative panels, Density board, and other four series of dozens of varieties, in the province and the country with the industry are renowned, and to achieve export. Top 10 brands of yellow cat. Jinan Huang Cat Wood Co., Ltd., founded in 2000, it mainly produces high-grade decorative plates and a variety of plywood. Is currently specializing in the production of sheet metal, plywood business.

- Q: Willow eucalyptus wood and pine which is good

- Many businessmen will use cheap wood eucalyptus, Malacca (another produced from Southeast Asia fast-growing cheap wood) core wood blockboard beautification into a "solid wood ecological board", attempt and solid wood detached, confuse, mislead consumers, but its essence Is still the use of cheap wood man-made sheet. The price is there. Pine, especially New Zealand pine widely used in the production of a variety of pine wood furniture, there are many specialized in the production of pine furniture brand, is also widely used in children's furniture and other fields. In addition, we must use a lot of glue and increase the risk of formaldehyde release. The plate will also increase the release of formaldehyde during the cutting process, and the same conditions do not have these problems. Of course, the use of blockboard can save a lot of cost, so for decoration, props production, especially public commercial space project is still very meaningful. So in general, a kind of wood is not dare to show his face, a large square is made of solid wood furniture wood. Combined with the actual value of the two woods in reality, and their application effects. Pine should be excellent and willow eucalyptus wood, Malacca.

- Q: What kind of sheet is more environmentally friendly?

- Norby forest plate are more environmentally friendly E1 level is the formaldehyde emission is 1:00, E0 level is 0:00, of course, E0 level more environmentally friendly

- Q: What is the meaning of C in 13.5 * 1500 * C in plate specifications?

- In front of the thickness and width, C said length, according to need to determine.

- Q: How is the environmental standard of the plate defined?

- According to China's environmental standards, according to the concept of formaldehyde emission limit, the limit of formaldehyde in the plate is divided into three levels, namely E2 ≤ 5.0mg / L, E1 ≤ 1.5mg / L, E0 ≤ 0.5mg / L The Plate to meet the E2 level standard, that is, E2, E1 and E0 class plate can be called the green sheet, but because of consumer awareness of environmental protection, and now the market more common E1 or even E0 grade plate. ???? E0 standard is to allow formaldehyde in the plate, but can not exceed 0.5mg / L, which is the highest upper limit; the lower limit should be the highest content of wood aldehyde itself (wood self-aldehyde content is generally 0.12mg / L-0.04mg / L) That is the lower limit is 0.12mg / L. ??? "Zero formaldehyde" is the choice of non-formaldehyde, the production process does not produce aldehyde; on the environment of the production staff do not bring any pollution and injury. From this we can give "zero formaldehyde" plate so that the free aldehyde in the plate is less than or equal to the content of the wood itself (usually 0.04mg / L-0.12mg / L). "Zero formaldehyde" sheet and E0 is not the same thing, "zero formaldehyde" sheet principle that higher than the E0 level.

- Q: What is FR4 sheet

- FR-4 is a glass fiber epoxy resin CCL, a circuit board in the substrate, in fact, you should have seen, such as the kind of small game machine to open, inside the green board is FR-4 to do circuit board.

- Q: What is the sheet of Sophia Wardrobe?

- Should be Malacca ecological board or the European pine board OSB,

- Q: Why is the PTFE sheet so slippery?

- In the plastic commonly known as "plastic king" of the PTFE plate, with excellent chemical resistance, corrosion resistance, aging resistance, self-sealing, non-stick, non-scaling and other excellent performance. Applicable equipment: the reactor, storage tanks, valves and containers lining, gaskets and so on.

- Q: My family smokers next to the installation of a natural gas using a firearm, the two appliances exhaust pipe close to the natural gas company in the safety inspection that is very dangerous, between the two exhaust pipe to use the same fire with fire Of the plate, but I do not know which type of plate to use, please know the answer. I am good to buy

- Fu Mei home fire board, you can go to the market to understand what

- Q: Is the picture below the S modeling faculty do very stiff want to achieve this and exactly the same effect Thank you!

- You can use the relatively soft wood to do, or use three-dimensional plastic to do, and then add a little sponge like plastic sofa.

Send your message to us

PVC Foam Sheet lowes polycarbonate panels roofing sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords