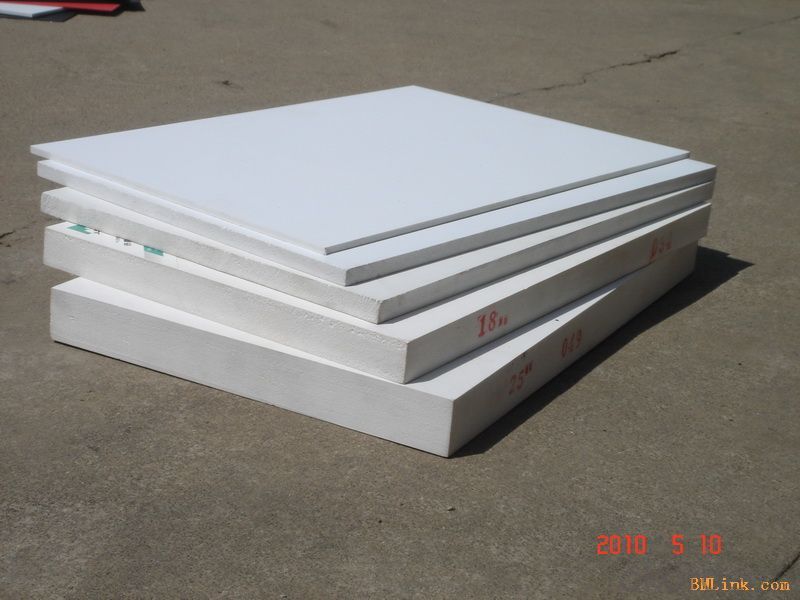

PVC Foam Board, PVC Rigid Foam Board, PVC Celuka Board

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Introduction

PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight

Applications

1.exhibition desk, Shelve in supermarket

2.Advertisemen Board and sign board

3.the advertisement sheet for printing,engraving,cutting,sawing

4.Architectural decoration and upholstery

5.decoration for partition wall and shopwindows

6.Waterproof,anticorrosive,metabolic and recyclable,moisture

Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation,noise absorption,heat preservation and anti-corrosion.

(3) Tough,rigid with a high impact strength,not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Environmental-friendlygreen and lead-free.

Specification

Usage Life |

more than 50 years |

Hardness | ≥10Mpa |

Elongation at Break | ≥10% |

Water Absorption | ≤1.0% |

Application | Wall cladding, decorating shelf, etc |

Photos

- Q:What is the quality of the board?

- The use of environmental protection factor is higher than the national standard 18mm thickness of the MDF, and the new PVC louver with a different from the general wood sheet of polymer synthetic fiber material, after 200 degrees Celsius Of the high temperature without plastic hot veneer treatment, completely free formaldehyde release. This ensures that the production of "starting line" to reduce the formaldehyde content. The quality of formaldehyde is less than or equal to 1.5mg / L, and the formaldehyde content of E1 grade (national mandatory standard) is less than or equal to 1.5mg / L

- Q:TR90 memory board frame is what?

- In fact, there is no such frames, TR90 frame with the plate is different. 1, from the material comparison: TR90 frame is the use of nylon material (also known as nylon 12 or PA12), is the most popular ultra-light frame material, with light weight, good toughness, super safety and other characteristics, with super Flexibility, wear in motion will never break. (Except fake and shoddy products). Plate frame is the use of acetate fiber or propionic acid fiber. Injection molding or suppression of grinding production. 2, the process comparison: TR90 frame process complex, the injection of glass factory and spray paint process requirements are relatively high. Plate rack: Although the plate rack less painting, but in the work than the TR90 frame process to be much more, more complex process. 3, the use of comparison: TR90 Frame: light weight, comfortable to wear, more secure, more difficult to deformation. The only drawback is that it will fade. Plate frame: the same size of the frame relative to the TR90 frame will be more weight, the bridge of the nose will have the feeling of oppression, comfort is not as TR90 frame, flexibility and safety than the TR90 frame slightly worse. The advantages of three-dimensional sense of strong, three-dimensional edges and corners of the TR90 frame can not be compared, but also not out of color. )

- Q:Huaxiang plate how?

- Huaxiang plate is a well-known brand in Guangdong Province, the quality is very good! Decoration master are recommended to use this one sheet.

- Q:How much is the quartz stone plate? What is the specification?

- Quartz stone specifications in more than 2440 * 700, there are width of 750,760, monochrome more than 400 yuan a money, there are 3050 * 1400 a large board more than 1400 or more, this is the ordinary grade Of the quartz stone of the manufacturers, not transportation, loss and processing costs, mainly to see the brand and color equipment is good or bad, the quality of OK higher prices. Do quartz stone to find [artificial stone processing plant]

- Q:Now I'm going to calculate a display panel for the material sheet, and I'm ready to calculate the square of the plate! The data is: length [1200MM] width of [750MM] thickness of [480MM] material name is [white light paint] how to calculate how many squares to use it? Jaya! Say it! I put the remaining 5 points all to You say that one of them.

- Is it not your cabinet High: 1200 Width: 750 Depth: 480? The cabinet you have to open. There are two side panels, a roof a floor, a backplane, but you have to know there is no solid and activities Plywood. According to your size: 1.2 * 0.48 * 2 = 1.152 0.75 * 0.48 = 0.72 1.2 * 0.75 = 0.9 Probably square: 2.78. Just a mao count, there is a board where I have not subtracted.

- Q:How does the composite sheet distinguish between acrylic and PC?

- Do not know what you said PC is what, acrylic, well recognized ah, take a lighter, get one or two acrylic point, and burn nothing is acrylic, understand?

- Q:601 grades of stainless steel, would like to know its chemical composition and use, thank you!

- NAS 601 60Ni-23Cr-1AI-0.2Ti Mainly used for gas turbine parts, heat treatment furnace parts.

- Q:How to color the plate after carving

- When the font is colored, the first pigment (such as gold powder, silver powder, etc.), with ordinary office glue mixed mix, drop a few drops of diesel, pay attention not to be too thin, with the mud of the kind of sand sand wall can be almost , And then placed on the carved panel, with a thick plastic sheet, (the best use of silk screen with the kind of scraper), gently scraping past, the pigment will stay in the concave font, In the outside of the paint with a soft damp cloth can be wiped, and some also use advertising pigments instead of color.

- Q:Cedar Blockboard Good and Pure Wooden Plate Which is good?

- See you use the scope of what to use, but relatively do not consider the price or solid wood is good. Blockboard is a solid wood board joinery board, also known as Daixin board, the logs cut into pieces, stitching into a core, Because the main are solid wood, so many sales staff will be said to be environmentally friendly sheet, in fact, like a large core board is containing the man-made adhesive sheet. Three hydrogen ammonia plate is the MDF, with this material to do the surface of the plate are called three hydrogen ammonia plate, and the substrate is the same, and MDF, particleboard and so can be made of three hydrogen ammonia plate. Solid wood panels are durable, natural lines, mostly natural wood unique aroma, with good hygroscopicity and permeability, good for human health, does not cause environmental pollution, is the production of high-grade furniture, decoration of the high-quality housing plate. Some special materials (such as beech) solid wood board or the manufacture of buttocks, precision instruments ideal material.

- Q:What is FR4 sheet

- FR-4 is a glass fiber epoxy resin CCL, a circuit board in the substrate, in fact, you should have seen, such as the kind of small game machine to open, inside the green board is FR-4 to do circuit board.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Foam Board, PVC Rigid Foam Board, PVC Celuka Board

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords