Semi Gloss PVC Electrical Insulation Tape with Good Adhesion

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PVC Tape

PVC tapes are made of soft pvc film coated with rubber pressure-sentitive adhesive.

Application of PVC Tape

PVC tapes are widely used in auto harness, wrapping of wire, and insulation protection. It is the main insulation material of automobilehousehold electrical apparatus.

Advantage of PVC Tape

Corrosion protection for metal piping systems above and below ground.

Corrosion protection for fittings and joints on mill coated pipe.

Corrosion protection of electrical conduit & fittings.

Resists corrosive action by salt water, soil acids, alkalies and salts.

Prevents dielectric corrosion between buried steel pipe and soil minerals.

Pictures of PVC Tape

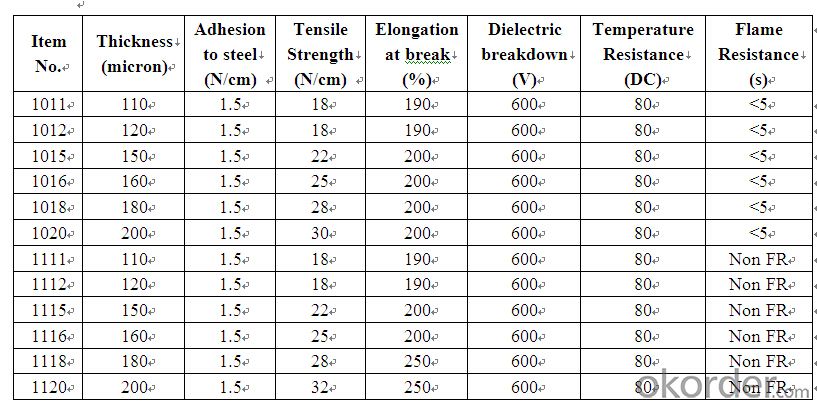

Specification of PVC Tape

FAQ

1. What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4.Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

- Q: How do you remove packaging tape without leaving residue?

- To remove packaging tape without leaving residue, you can try using a hairdryer to gently heat the tape. This will help loosen the adhesive, making it easier to peel off without leaving any sticky residue behind. Additionally, using a rubbing alcohol or vinegar solution can help dissolve any stubborn residue that may be left behind. Just apply the solution to a cloth and gently rub the area until the residue is gone.

- Q: Can packaging tape be used for labeling?

- Yes, packaging tape can be used for labeling. While packaging tape is primarily used for sealing packages and boxes, it can also serve as a convenient way to label items. By writing directly on the tape or attaching a paper label to it, you can easily identify the contents of a package or mark it for specific purposes. However, it is important to note that using packaging tape for labeling may not be as durable or long-lasting as using dedicated label materials. Additionally, the adhesive on packaging tape may not be as strong as that on specialized labels, which could lead to labels falling off or becoming less visible over time. Therefore, while packaging tape can be used for labeling in some cases, it may be more suitable for short-term or temporary labeling needs.

- Q: What are the considerations for using packaging tape on fragile items like ceramics?

- When using packaging tape on fragile items like ceramics, there are several important considerations to keep in mind. Firstly, it is crucial to select the appropriate type of packaging tape. Look for tape that is specifically designed for fragile items or delicate surfaces, as it will typically have features such as gentle adhesive and high tensile strength. This type of tape is less likely to damage or leave residue on the ceramics. Secondly, it is important to handle the ceramics with care when applying the tape. Avoid applying excessive pressure or force that could potentially cause them to crack or break. Additionally, make sure to clean the surface of the ceramics before applying the tape to ensure proper adhesion. Another consideration is the amount of tape that should be used. While it is important to secure the ceramics adequately, using too much tape can add unnecessary weight and potentially damage the fragile item. It is advisable to use just enough tape to hold the ceramics securely in place without putting excessive strain on them. Furthermore, it is recommended to use additional protective materials in conjunction with the packaging tape. Bubble wrap, foam sheets, or packing peanuts can provide extra cushioning and protect the ceramics from any potential impact or vibrations during transit. Lastly, it is crucial to label the package as fragile to ensure that handlers are aware of the delicate contents. This can help to minimize the risk of mishandling and provide an extra layer of caution during transportation. In conclusion, when using packaging tape on fragile items like ceramics, it is important to choose the appropriate type of tape, handle the ceramics with care, use the right amount of tape, employ additional protective materials, and clearly label the package as fragile. By considering these factors, you can help to ensure the safe transportation of your fragile ceramics.

- Q: Can packaging tape be used for sealing fabric?

- While packaging tape can be used to seal fabric to a certain extent, it is not the ideal choice for extended or heavy-duty usage. The main purpose of packaging tape is to seal boxes and packages, so although it might temporarily suffice for fabric, it may not offer a firm and long-lasting hold. Moreover, there is a possibility that packaging tape could leave behind sticky residue on the fabric or harm delicate materials. It is advisable to opt for fabric-specific tapes or adhesive products explicitly created for sealing fabric, as they offer superior adhesion and are less likely to result in damage.

- Q: Can packaging tape be used for sealing automotive parts or equipment?

- Packaging tape is typically not recommended for sealing automotive parts or equipment. While packaging tape is designed to securely seal cardboard boxes and other lightweight materials, it may not offer the necessary durability and adhesive strength required for automotive applications. Automotive parts and equipment are subjected to various conditions such as heat, vibrations, and exposure to chemicals, which can cause packaging tape to degrade or lose its adhesive properties over time. Additionally, automotive parts and equipment often require a more specialized sealing method, such as gaskets, seals, or specific automotive-grade adhesives, to ensure proper functionality and longevity. Therefore, it is generally best to use appropriate sealing methods and materials specifically designed for automotive applications to ensure the desired performance and reliability.

- Q: Is packaging tape resistant to chemicals or solvents?

- Generally, chemicals and solvents do not pose a threat to packaging tape. Packaging tapes are typically composed of materials like polypropylene or polyvinyl chloride (PVC), which possess excellent chemical resistance. These materials are specifically engineered to endure exposure to a broad array of chemicals and solvents commonly found in industrial or commercial settings. Nevertheless, it is crucial to acknowledge that the resistance of packaging tape may differ depending on factors such as the brand, type, and quality of the tape. Consequently, it is advisable to review the product specifications or seek guidance from the manufacturer to obtain detailed information regarding the chemical resistance of a particular tape.

- Q: How is packaging tape different from regular tape?

- Packaging tape is specifically designed for sealing boxes and securing packages during shipping or storage. It is typically wider, stronger, and more durable than regular tape, making it capable of withstanding the rigors of transportation. Regular tape, on the other hand, is generally used for lighter tasks like wrapping gifts or hanging lightweight objects.

- Q: As for the title, just bought the tape cutter, but I don't know how to use it. I bought it in plastic. Used for packing express boxes. It's better to use a process chart for me to see.. Thanks。。 Or clear words can also...

- How do I fit the tape onto the sealing machine?There is no machine, or else let you have a look

- Q: What is the average width of packaging tape?

- Packaging tape usually has an average width ranging from 1.88 inches to 2 inches. This standardized width ensures effective sealing of boxes and packages, ensuring a secure and dependable closure. Nevertheless, it is worth noting that the market offers different tape widths to cater to specific packaging requirements or personal preferences, with some tapes being narrower or wider.

- Q: Can packaging tape be used for sealing storage containers?

- Packaging tape is an ideal choice for sealing storage containers. Its design focuses on delivering a strong and secure seal for a variety of materials, including storage containers. The packaging and shipping industries frequently rely on it to seal boxes, cartons, and other containers. Thanks to its robust adhesive, packaging tape can withstand the challenges of storage and transportation, guaranteeing the safety and protection of container contents. Moreover, its application is effortless, and it offers a dependable seal that effectively keeps dust, dirt, and moisture from infiltrating the storage container. Hence, utilizing packaging tape for sealing storage containers proves to be a practical and efficient solution.

Send your message to us

Semi Gloss PVC Electrical Insulation Tape with Good Adhesion

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches