Modern PVC Ceiling - High Quality PVC Crust Foam Sheet 1-33mm with Reasonable Price

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PVC Foam Board

1. Product Introduction

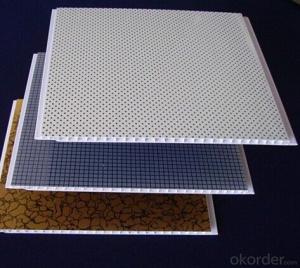

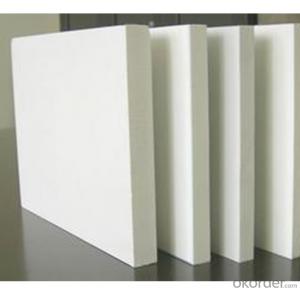

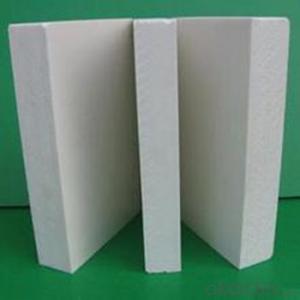

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

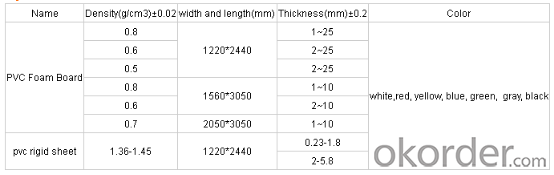

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

3. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

4. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

- Q: Can I put tiles on the PVC gusset?

- Really can not, the main reason is unable to construction, first PVC surface and the tile can not use cement mortar and other bonding, followed by sub-plate to bear the lack of capacity. Now a lot of grass-roots board, FC board, cement pressure board and so can be pasted tiles, and not necessarily have to brick

- Q: Pvc board how how sticky cement wall

- Direct sticky cement wall is not strong, it should add a layer of isolation board, playing a bottom, with structural glue can stick

- Q: How do I find customers who need PVC flooring?

- You can through the e-commerce B2B platform bar. Like Alibaba, Made in China, Global Sources, HC Network, etc. ~ Although the free membership of the information source is relatively small, but registered as a free member no defense, more than one channel more opportunities.

- Q: Can the interior wall be decorated with pvc board?

- PVC board is a vacuum plastic film, used for various types of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foam board.

- Q: It is said that the PVC board is divided into several categories, their respective types of what is the difference between the use, I would like to ask, who can tell me, thank you,

- As far as I know, it should be the production process is divided it? Extrusion plate and into the pressure plate is the size of the size can not change the difference.

- Q: Pvc polymer composite board about how much money? Is calculated in meters? Or square?

- According to the new material, back to the material, color, weight, quality and other prices are different, as the kg or square price can be calculated to see the specific needs of customers, in fact, can be converted, are the same.

- Q: Pvc floor construction costs how much money a square meter

- PVC flooring, also known as plastic flooring, different names are different in different regions, there are people called plastic flooring, plastic sheet, floor glue, plastic floor, the floor of the floor called leather floor, the exact name should be PVC flooring. Because the floor is the main use of PVC (commonly known as PVC or plastic) materials processing and production of ground decoration materials, so the floor called PVC floor. PVC flooring according to the shape points: PVC coil flooring and PVC sheet flooring 2 kinds. PVC floor by structure: composite PVC flooring and homogeneous heart through the PVC floor 2.

- Q: Wardrobe sliding door with health wood and PVC which is good? How big is the price difference? Please list the advantages and disadvantages separately.

- Health wood and plastic PVC is the same thing, health is a sign, wood plastic is also called PVC, there is called hollow, the current wooden panels do closet door is more environmentally friendly and healthy, the price and density board is a square difference is 30 yuan about. At present, the materials used to do the closet door are: MDF, pvc board, tempered glass, steel plate, blockboard, paint board, finger plate, solid wood board. MDF: solid wood strong sense, easy to absorb moisture, easy to deformation, formaldehyde easily exceeded. Wood plastic: moisture, light texture, solid wood feel bad, not easy to deformation. Strengthen the glass: material environmental protection, light transmission is good, easy to do patterns and color, bulky, there are security risks. Plastic steel plate: the new material on the market, you can soak and not easy to deformation, high strength, expensive. Blockboard, finger board, solid wood can be called solid wood, but later to paint treatment, it is not environmentally friendly, less style, not easy to match.

- Q: Finished pvc board how to install the kitchen led lights

- Open a hole, then a good line, fitted with lights, card buckle. Installed.

- Q: MD board and pvc board which do better TV wall

- Pvc board compared to the MDF, more suitable for use as a TV wall material. PVC foam board with anti-corrosion, moisture, mildew, non-absorbent, easy to thermoforming and other characteristics, it is widely used in furniture, cabinets, bathroom cabinets, exhibition racks, box core, indoor and outdoor decoration, building materials, chemicals Field with board. MDF, also known as fibreboard, is made of wood fiber or other plant fiber as raw material, urea-formaldehyde resin or other suitable adhesive made of man-made sheet. Density board due to the soft impact resistance, but also easy to reprocess, in foreign countries is a good material for the production of furniture, but because the country on the high density board standards than the international standard several times lower, so the use of MDF quality Still need to be improved. Density board is the biggest drawback is not moisture, see the water on the swell. In the use of MDF do skirting board, door panels, windowsill board should pay attention to six sides are painted, so that will not be deformed.

Send your message to us

Modern PVC Ceiling - High Quality PVC Crust Foam Sheet 1-33mm with Reasonable Price

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords