PVC Coated Wire Mesh Fencing Hardware Cloth

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Coated Wire Mesh Fencing Hardware Cloth

1. Structure of PVC Coated Wire Mesh Fencing Hardware Cloth Description:

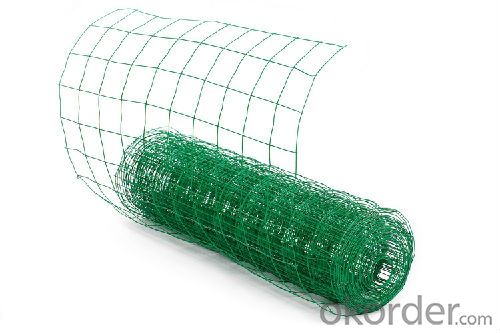

PVC Coated Wire Mesh Fencing Hardware Cloth is made of high quality steel wire, Various configurations and sizes, Suitable for shotcrete applications, constructed with galvanized iron wire of high quality. It has PVC powder covering that is processed by an automatic machine. The smooth plastic coating on this corrosion protective wire is attached with a strong adhesive which make increases durability of the wire.

PVC Coated Wire Mesh Fencing Hardware Cloth is mainly for the animals fence, supermarket shelves, interior decoration, poultry, flowers and trees fences, outdoor for villas, residential segregation wall, the product has a distinctive color, beautiful, corrosion and rust, fade, UV and so on.

2. Main Features of PVC Coated Wire Mesh Fencing Hardware Cloth:

• Age residence

• Antirust

• Durable

• Beautiful shape

• Good anti-corrosion

• Easy installation

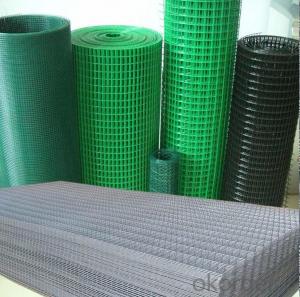

3. PVC Coated Wire Mesh Fencing Hardware Cloth Images

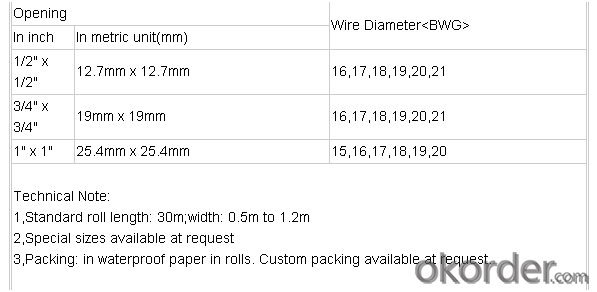

4. PVC Coated wire mesh Specification

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your PVC Coated Wire Mesh Fencing Hardware Cloth?

Our company is the professional manufacture of PVC Coated Wire Mesh Fencing Hardware Cloth and any other wire mesh. We have more than 15years experience in producing welded wire mesh. Based on our experience, with our reasonable price, high quality and considerate service, our products enjoy high reputation in our market. Our main products like PVC Coated Wire Mesh Fencing Hardware Cloth, hot rolled steel plate/coil, cold rolled steel coil, gi steel coil, pp gi coil, corrugated sheet, wire rod and so on. We have established business relationships with clients in the Southeast Asia,South Asia, North America, and many other countries and regions.

② The reason why you choose us

· Diversification of products

. Professional sales team

· Industry experience over 15 years

· Shipment of goods -More than 50 countries worldwide

· We have the most convenient transport and prompt delivery

· We offer competitive price with best service

· We have win high reputation based on best quality products

③ How long can we receive the product after purchase?

In the purchase of PVC Coated Wire Mesh Fencing Hardware Cloth within three working days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: PE copper mesh skeleton plastic composite pipe connection in several ways?

- The hot-melt connection is to insert the composite pipe into the hot-melt pipe, and the electric wire embedded in the inner surface of the pipe is energized to heat it.

- Q: Can steel wire mesh be customized in terms of wire thickness?

- Yes, steel wire mesh can be customized in terms of wire thickness. The wire thickness can be adjusted according to specific requirements and applications.

- Q: Can steel wire mesh be bent?

- Yes, steel wire mesh can be bent. Steel wire mesh is a flexible material that can easily be manipulated into various shapes and forms. It can be bent using different tools, such as pliers or wire cutters, to achieve the desired shape or curvature. The flexibility of steel wire mesh allows it to be used in a wide range of applications, including construction, landscaping, and industrial purposes. However, the degree to which steel wire mesh can be bent may depend on its thickness and strength. Thicker and stronger wire mesh may require more force or specialized equipment to bend.

- Q: What are the different types of coatings available for steel wire mesh?

- There are several types of coatings available for steel wire mesh, each offering unique properties and benefits. 1. Galvanized coating: This is the most common type of coating for steel wire mesh. It involves applying a layer of zinc to the surface of the mesh to protect it from corrosion. Galvanized coatings can be either hot-dip galvanized or electro-galvanized, with hot-dip offering better corrosion resistance. 2. PVC coating: PVC (polyvinyl chloride) coating is used to provide additional protection to steel wire mesh. It involves applying a layer of PVC material to the surface of the mesh, which helps prevent corrosion and provides a smooth and aesthetically pleasing finish. PVC coatings are available in various colors to meet specific requirements. 3. Epoxy coating: Epoxy coatings are commonly used for steel wire mesh in applications where chemical resistance is required. These coatings offer excellent adhesion and provide a protective barrier against corrosion, chemicals, and abrasion. Epoxy coatings are available in different formulations to suit various environmental conditions. 4. Polymer coating: Polymer coatings, such as polyethylene and polypropylene, are applied to steel wire mesh to enhance its durability and resistance to corrosion. These coatings are often used in outdoor or marine environments where exposure to moisture and chemicals is common. Polymer coatings also provide insulation properties and can be UV resistant. 5. Stainless steel coating: In some cases, stainless steel wire mesh is used instead of regular steel wire mesh. Stainless steel itself is a corrosion-resistant material, so it does not require any additional coatings. The stainless steel composition provides excellent durability and resistance to rust and corrosion, making it a popular choice for harsh environments. It is important to consider the specific application and environmental conditions when selecting a coating for steel wire mesh. Each type of coating offers different advantages, so choosing the right one will ensure optimal performance and longevity of the wire mesh.

- Q: How does steel wire mesh perform in terms of durability and long-term use?

- The exceptional durability and long-term performance of steel wire mesh are widely recognized. This is due to its composition of steel, which is renowned for its strength and resilience. Steel wire mesh has the ability to withstand heavy loads, harsh weather conditions, and potential impacts or stress, making it a reliable choice for construction, industrial, and agricultural sectors. The durability of steel wire mesh is further enhanced through the process of galvanization or coating with a protective layer of zinc. This galvanized layer acts as a barrier against corrosion and rust, significantly extending the mesh's lifespan. As a result, steel wire mesh can maintain its structural integrity and functional properties even when exposed to moisture, chemicals, or other corrosive elements. Additionally, steel wire mesh has excellent resistance to wear and tear, making it suitable for demanding and high-impact environments. Its high tensile strength ensures it can withstand significant forces without deformation or breakage, providing long-term reliability and stability. When it comes to long-term use, steel wire mesh offers numerous advantages. It is highly versatile and adaptable, allowing for a variety of applications such as fencing, reinforcement, filtration, and separation. Its durability and strength make it ideal for constructing sturdy barriers, cages, or enclosures that require long-lasting performance. Furthermore, steel wire mesh is relatively low maintenance, requiring minimal attention and upkeep to maintain its functionality. It does not need regular painting or coating, reducing maintenance costs and efforts over time. In conclusion, steel wire mesh excels in terms of durability and long-term use. Its robustness, resistance to corrosion, and ability to withstand significant loads make it a reliable choice for various applications. With proper installation and maintenance, steel wire mesh can provide a dependable solution that ensures longevity and performance.

- Q: How is steel wire mesh used in reinforcement of airports?

- Steel wire mesh is commonly used in the reinforcement of airports due to its strength, durability, and ability to provide structural support. It is primarily used in concrete applications to enhance the strength and integrity of the airport infrastructure. In airport runways, steel wire mesh is often embedded within the concrete pavement to increase its load-bearing capacity. The mesh acts as a reinforcement, distributing the weight of heavy aircraft and vehicles more evenly across the runway surface. This helps to prevent cracking and rutting, ensuring a smoother and safer landing and takeoff experience for airplanes. Additionally, steel wire mesh is utilized in the construction of airport taxiways, aprons, and parking areas. These areas are subject to high traffic and heavy loads, making them prone to cracking and deterioration over time. By incorporating steel wire mesh into the concrete during construction, the mesh provides an added layer of reinforcement, enhancing the overall strength and durability of these surfaces. Furthermore, steel wire mesh can also be used in the construction of airport perimeter fences and security barriers. The mesh is woven tightly together, creating a strong and secure barrier that helps prevent unauthorized access to sensitive airport areas. This not only enhances the security of the airport but also ensures the safety of passengers and personnel. Overall, the use of steel wire mesh in the reinforcement of airports plays a vital role in maintaining the structural integrity and safety of airport infrastructure. Its ability to withstand heavy loads, prevent cracking, and provide security makes it an essential component in airport construction and maintenance projects.

- Q: What is the weight of steel wire mesh?

- The weight of steel wire mesh may differ based on various factors including wire thickness, wire diameter, mesh opening size, and overall panel dimensions. Steel wire mesh is typically available in different gauges, with weights per square foot or square meter corresponding to the gauge. For instance, a light gauge steel wire mesh could weigh approximately 0.5 pounds per square foot (2.45 kilograms per square meter), while a heavy gauge mesh might weigh around 2 pounds per square foot (9.8 kilograms per square meter). It is important to note that these weights are approximate and subject to variation depending on the specific specifications and manufacturing processes of the steel wire mesh.

- Q: What are the cost considerations for steel wire mesh?

- There are several factors to take into account when considering the costs of steel wire mesh. The cost of the mesh will be significantly influenced by its size and dimensions. Larger and more intricate designs will generally be more expensive than smaller and simpler ones. The thickness and grade of the steel used in the mesh will also impact the cost. Thicker and higher-grade steel will typically be more expensive due to the increased material cost and potential for higher manufacturing expenses. Another crucial consideration is the quantity of steel wire mesh required for a project. Purchasing in bulk or larger quantities may often result in volume discounts and lower unit costs. Conversely, smaller quantities may lead to higher prices due to increased handling and packaging costs. Moreover, the cost of steel wire mesh can be affected by the complexity of the manufacturing process. Certain designs may require more intricate weaving or welding techniques, which can increase labor and production expenses. Additionally, the need for specialized equipment or tools during manufacturing can contribute to higher costs. Transportation and delivery costs should also be taken into account. The weight and size of the steel wire mesh can impact shipping expenses, particularly for long-distance transportation. Lastly, the cost of steel wire mesh can be influenced by market conditions and fluctuations in the price of steel. As steel is a commodity, its price can vary based on supply and demand factors, as well as global economic conditions. Therefore, it is crucial to monitor market trends and consider potential price changes when evaluating the overall cost of steel wire mesh.

- Q: How is steel wire mesh used in reinforcement of waste treatment facilities?

- Due to its high tensile strength and durability, steel wire mesh is frequently utilized in waste treatment facilities to reinforce the structures that contain and store waste material. These facilities involve various processes, such as waste collection, sorting, and treatment, which generate a significant amount of waste material requiring storage or containment. The primary objective of employing steel wire mesh is to bolster the structural integrity and strength of the concrete used. During construction, the mesh is typically incorporated into the concrete mixture, forming a grid-like pattern that provides reinforcement throughout the structure. This reinforcement helps distribute and withstand the forces and pressures exerted by the waste material on the concrete walls, floors, and tanks. Moreover, steel wire mesh also serves to prevent cracking and enhance the overall durability of the concrete structures. Acting as a reinforcement layer, the mesh holds the concrete together, minimizing the risk of cracks and ensuring the structure remains intact over time. Additionally, steel wire mesh can be applied to reinforce concrete pipes and drainage systems in waste treatment facilities. These pipes and systems are essential for efficient waste and wastewater management and disposal. By reinforcing them with steel wire mesh, their strength and resistance to external forces are improved, enabling them to withstand the demands of waste treatment processes. In conclusion, steel wire mesh plays a crucial role in reinforcing waste treatment facilities, as it enhances the strength, durability, and structural integrity of the concrete structures. It provides a reliable solution for withstanding the forces and pressures exerted by waste materials, ensuring the long-term functionality and safety of these facilities.

- Q: What are the different coating options available for steel wire mesh?

- There are several different coating options available for steel wire mesh, each offering different benefits and functionalities. Some of the most common coating options include: 1. Galvanized Coating: Galvanization is a process where a layer of zinc is applied to the steel wire mesh. This coating provides excellent corrosion resistance, making it suitable for outdoor applications and environments with high moisture or chemical exposure. 2. PVC Coating: PVC (polyvinyl chloride) coating is a type of plastic coating that is applied to the steel wire mesh. This coating provides protection against corrosion, as well as abrasion resistance and electrical insulation. PVC coating is often used in applications where durability and aesthetics are important, such as fencing or decorative applications. 3. Epoxy Coating: Epoxy coatings are a type of thermosetting polymer that provides excellent chemical resistance and durability. This coating is often used in industrial applications where the wire mesh is exposed to corrosive chemicals or harsh environments. 4. Powder Coating: Powder coating is a dry finishing process where a powder is applied to the steel wire mesh and then cured under heat to form a protective layer. This coating offers excellent durability, scratch resistance, and a wide range of color options. Powder coating is commonly used in architectural and decorative applications. 5. Stainless Steel Coating: Stainless steel wire mesh is already corrosion-resistant, but if additional protection is required, a stainless steel coating can be applied. This coating enhances the mesh's resistance to rust and corrosion, making it suitable for applications in marine environments or where exposure to salt or chemicals is a concern. 6. Teflon Coating: Teflon, or polytetrafluoroethylene (PTFE), coating is a non-stick coating that provides excellent chemical resistance and low friction properties. This coating is often used in applications where the wire mesh needs to be resistant to sticking or fouling, such as in food processing or filtration systems. These are just a few of the many coating options available for steel wire mesh. The choice of coating will depend on the specific requirements of the application, such as the desired level of corrosion resistance, durability, aesthetics, or functionality needed. It is important to consult with a knowledgeable supplier or manufacturer to determine the most suitable coating option for a particular project.

Send your message to us

PVC Coated Wire Mesh Fencing Hardware Cloth

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords