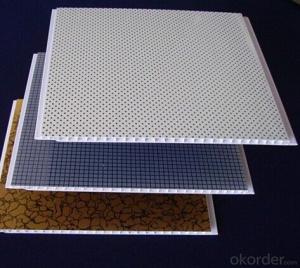

Outdoor PVC Ceiling Panels - PVC Celuka Foam Board Plastic Sheet for Advertising

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

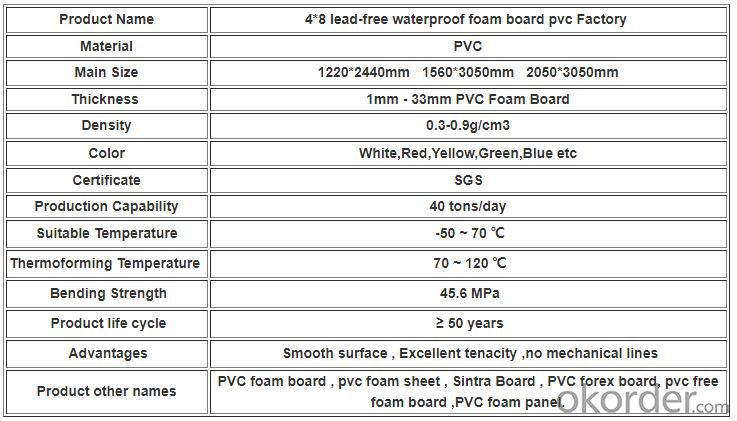

Specification

Specification

Features

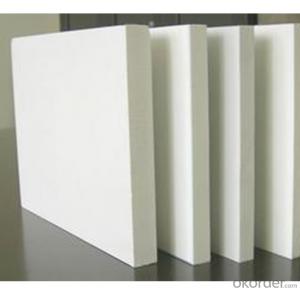

Light weight,good tenacity, high rigidity, fireproof and flame retardant, good insulation, no sopping, no deformation, easily to processed, good plasticity, being an excellent thermoform material, sub-light surface and elegant vision, anti-chemical corrosion, suitable to silk screen printing, with imported dyes, unfading and anti-aging.

Applications

As a Eco-friendly new material in 21st century,PVC foam board are wildly used all vareity of field in nowdays.

1.Advertising display board.

2.UV printing

3.Cabinet because of the waterproof, non-toxic,lead-free,can process as same as the wood but eco-friendly.

4. Home decorations

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Picture

- Q: Members XDJM: I work for reasons, a set of home hair blank room idle, recently wanted to simply rent out the rent. A friend said that the floor can be used home PVC floor shop, but we do not understand these things, please help my friends to answer my question, thank you: 1, the thickness of the general requirements of home PVC floor is how much? Requirements can not be easily trampled, hit rotten. 2, PVC floor of the construction conditions is what? Molding room floor can be used directly? 3, my home or the developer of the floor when the developer, the cement is not particularly flat (there are more holes, as if there is no cement road level), with what 4, some people say to brush plastic, need not? Hope that these or their own use of the reply, I only 30 points, all the reward

- You said the ground is not cement road level, there are a lot of holes, I do not know you are not the ground is the sand from the like, if there is a sand from the proposed you do not do cement self-leveling so that the quality of your floor There is no guarantee that the ground is not cement road Ping suggested that you do not do cement self-leveling and do not say how the effect of the cost is too high, the cement self-leveling to find someone to do the price of 15-25 yuan per square meter, and cement self-leveling Each can only do 2-4MM meters, that is to say that you want to make a good effect at least have to do 2 to 3 times, so the cost is too high, I do many years of PVC flooring, it is recommended that you shop The ground before the first to find a good way to find the mud on the ground so that you will be less to a lot of cost and the effect of the bottom out of the floor will be much better

- Q: Pvc stamina board can drill their own?

- Yes, but before installation, it is recommended to re-drill, according to the recommendations provided by the manufacturers to install, the plate itself has the characteristics of thermal expansion and contraction, need to reserve space. Hope that the above answer can help you, thank you.

- Q: Pvc foam board hardness how ah? Does anyone know not? Can you tell me?

- Co-extruded surface can reach Shore 85D, crust surface 60-65D

- Q: Stainless steel and pvc board bonding what adhesive

- Wear-resistant elbow special adhesive is a two-component enhanced paste adhesive, with high bond strength, low temperature curing performance, dry temperature of -40 ℃ ~ 300 ℃. Can be used for metal, ceramics, wood and other materials between the self-adhesive and mutual adhesion, is a wide range of structural binder. Second, the product characteristics High bond strength, toughness, good thixotropy Good resistance to aging Excellent resistance to water, oil, acid and alkali Third, the technical indicators Proportion (mass ratio) Hardness (Shore A) Peel strength (steel - steel) (25 ℃, 100g) is fully cured (25 ℃) A: B = 2: 180 ≥ 18Mpa ≤ 30min60min24h Fourth, the use of 1, the substrate treatment: before the removal of the substrate surface Dust, water, oil; metal should be polished, rust exposed metal color. 2, A, B components according to the mass ratio of 2: 1 mixed even after the glue.

- Q: PVC board and PVC pipe with the machine is the same?

- Extrusion equipment is almost the same, the difference lies in the die forming mold.

- Q: PVC board acid resistance?

- Hydrochloric acid concentration of 32%, the temperature of 50 degrees below the PVC board. no problem Temperature over 50 degrees with CPVC board, the cost of low available PP board, but the hardness and CPVC are different.

- Q: Will pvc, pp board how to calculate the weight of it! As well as pvc, pp board price!

- PP board density: 920-950KG / m? Weight of PVC board = length X width X thickness X density (1380KG / m? ~ 2200KG / m?) the lower the density the more expensive

- Q: PVC crust foam board business standards or national standards

- The true crust is made with a stoppage method, which forms a layer of dense hard crust on both sides of the sheet, which can improve the hardness and nail force of the plate. These physical properties are very important for the manufacture of furniture or for the decoration of the house. To identify the PVC board is (really) crust, in fact, very simple! As long as the shop does not pay attention to the thumb with the nail on the PVC board pressure, and then carefully check whether there is a deep dent, if there is, is clearly false, it is best not to. Celuka (Celuka) also known as controlled foam method, the current application is very wide, by the French gine kulmann company invented, it is the first patented one of the extrusion foam molding method. The principle of the Luca method is that the outer skin of the melt is compressed and cooled in the styling device directly connected to the die, and the mandrel in the cavity ensures that there is room left when the extrudate leaves the die Through the melt in the mold within the free foam is filled. Cooling strength, core mold size, extrusion speed, can affect the foam core layer density and outer crust thickness. The complex shapes of the profiles produced in this way have the characteristics of low density, high hardness and smooth surface. Baotian Hi-Tech can visit, in addition to their production of PVC crust foam board, but also the production of PVC own foam board, PVC foam profiles, product quality is in the high-end.

- Q: PVC board surface a lot of white spots, what is the reason?

- May be damp long moldy

- Q: Finished pvc board how to install the kitchen led lights

- Led light weight is very light, heat is also very small, can be installed directly.

Send your message to us

Outdoor PVC Ceiling Panels - PVC Celuka Foam Board Plastic Sheet for Advertising

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords