PVC Celuka Plastic Sheets / PVC Free Foam Plastic Sheets / PVC Sheet PVC Celuka Moulding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product Introduction

PVC foam sheet is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm,as your required

Thickness:1-33mm

Density:0.35-0.9

3.Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

4. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

5.FAQ

Q: What's the PVC Foam Sheet Processing performance?

A: 1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

Q: How many colors you have?

A: We have more than 100 existed colors. We can send the color swatch if you leave your message. Also customized colors are acceptable.

Q: If the products have some quality problem ,how will you deal with it?

A: 1,If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

2,Take measures to control quality strictly,we adhere to the principle: “ quality first”.

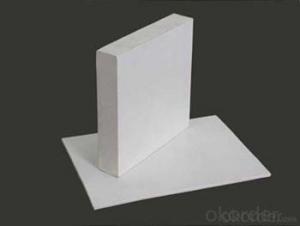

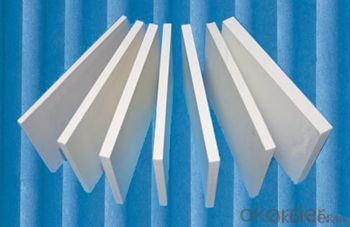

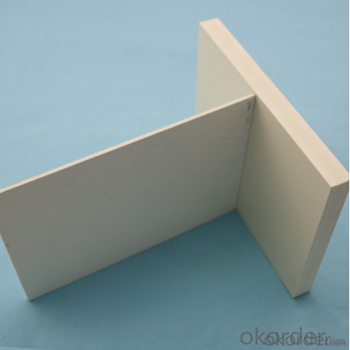

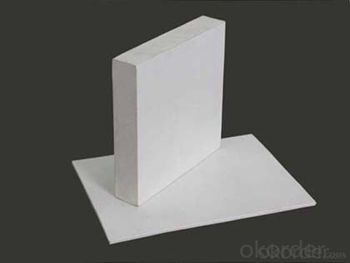

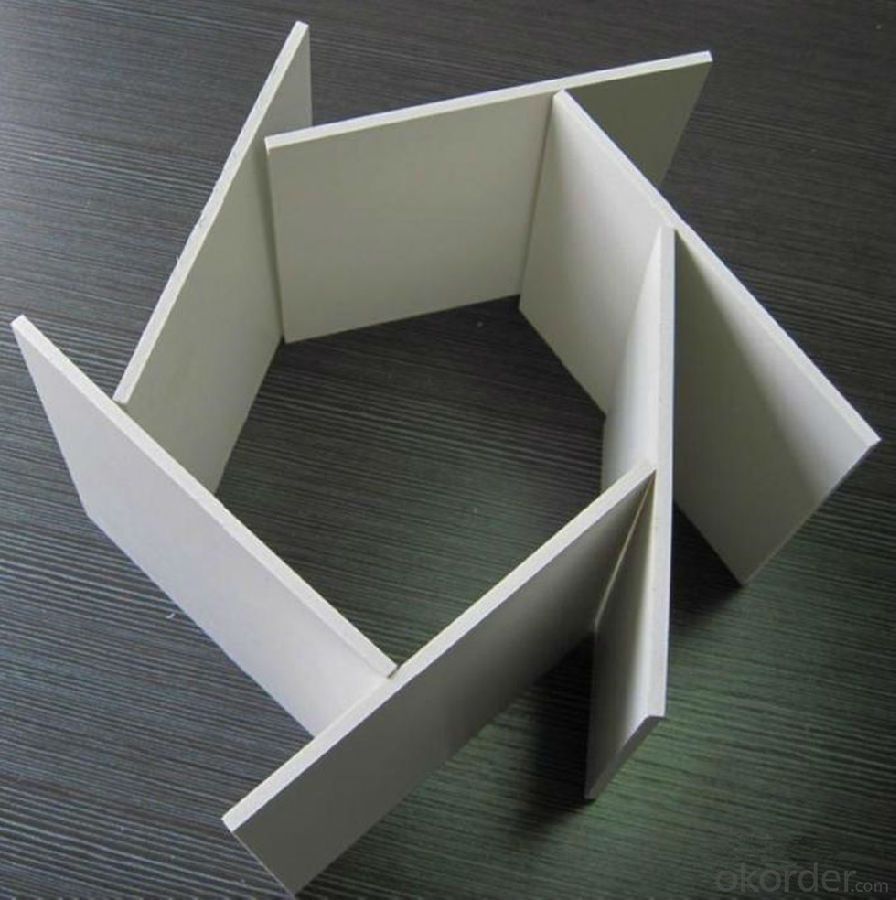

6. Pictures of PVC Foam Sheet

7.Pictures of Factory

- Q: How do plastic sheets compare to glass or acrylic?

- Plastic sheets, such as polycarbonate or PVC, offer several advantages over glass or acrylic. Firstly, they are much more durable and resistant to impact, making them ideal for outdoor or high-traffic areas. Plastic sheets are also lighter in weight, making them easier to handle and install. Additionally, plastic sheets are more cost-effective compared to glass or acrylic. However, glass and acrylic have better optical clarity and scratch resistance, making them suitable for applications where aesthetics and visibility are crucial. Ultimately, the choice between plastic sheets, glass, or acrylic depends on the specific requirements and priorities of the project.

- Q: What is the thickness range available for plastic sheets?

- The thickness range available for plastic sheets can vary greatly, ranging from very thin sheets measuring around 0.003 inches (0.076 mm) to thicker sheets measuring up to 2 inches (50.8 mm) or even more.

- Q: What happens if a clear lenticular (autostereoscopic) sheet is cut to size and placed over a 26 hdtv screen? Is there any type of 3D effect? (These type sheets are commonly used on greeting cards/trading cards/wall posters for a 3D-depth effect.) Thanks

- It wouldn't work as the picture underneath needs be printed in a special way too.

- Q: where can i buy like glass or plastic sheets/ walls in different sizes? Does home depot sell them? and how much are they?

- acrylic okorder ...

- Q: Can plastic sheets be bent or shaped?

- Yes, plastic sheets can be bent or shaped using various methods such as heat forming, vacuum forming, or cold bending techniques, depending on the type and thickness of the plastic.

- Q: What glue is the adhesive between aluminum and plastic in aluminum-plastic plate?

- The adhesion between aluminum plate and plastic plate is adhesive resin, which is a kind of hot-melt adhesiveThe product form is a kind of roll film, also called macromolecule adhesive filmSuch as DuPont, Korea SK, Japan MITSUBISHI, and so on, can provide quality products

- Q: How are plastic sheets manufactured?

- Plastic sheets are manufactured through a process called extrusion, where plastic pellets are melted and then forced through a die to form a continuous sheet. The sheet is then cooled and solidified before being cut into desired sizes.

- Q: where can i buy sheet plastic for seat covers ?

- if you have to put plastic on your furniture , to use it, then why have it ?

- Q: Can plastic sheets be bent or folded?

- Yes, plastic sheets can be bent or folded depending on their thickness and flexibility.

- Q: Can plastic sheets be used for protective shields in sports?

- Yes, plastic sheets can be used for protective shields in sports. They are commonly used in various sports such as hockey, baseball, and football to provide a barrier between players and potential injuries. Plastic sheets offer impact resistance, transparency, and lightweight properties, making them suitable for protecting athletes from flying objects or accidental collisions.

Send your message to us

PVC Celuka Plastic Sheets / PVC Free Foam Plastic Sheets / PVC Sheet PVC Celuka Moulding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords