Plastic Sheets - PVC Free Foam Board / PVC Sheet PVC Celuka Moulding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction

PVC foam sheet is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm,as your required

Thickness:1-33mm

Density:0.35-0.9

3.Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

4. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

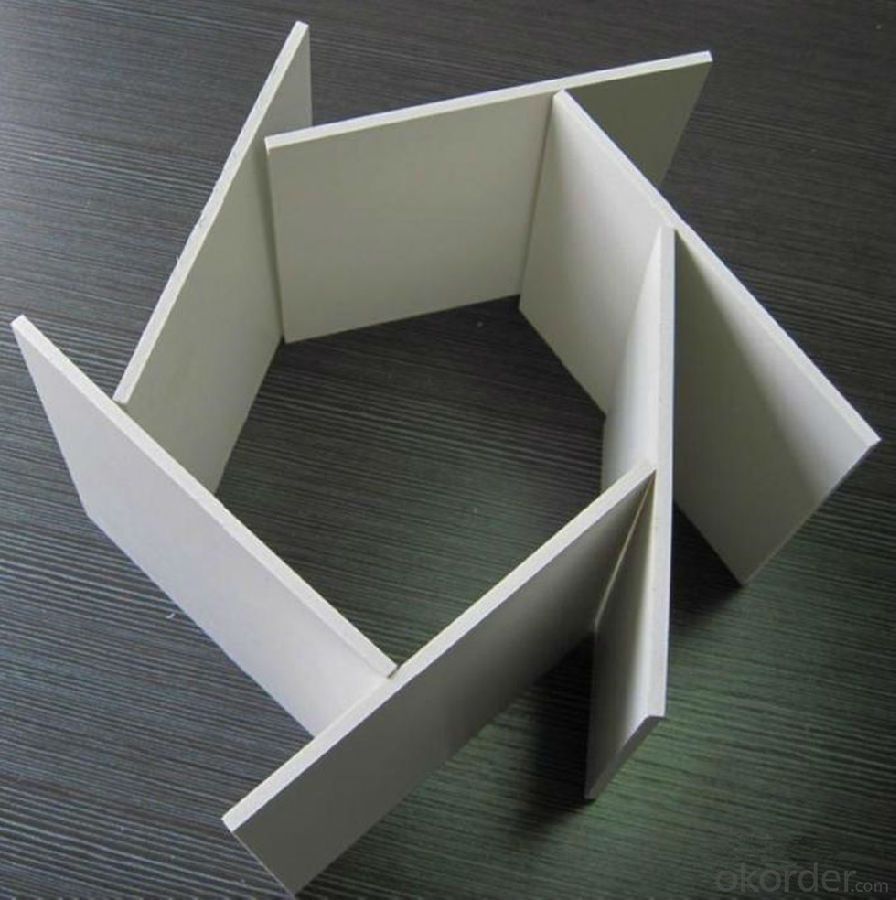

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

5.Additional customized properties

Impact strength/izod impact strength

corrosion-resistance

anti-aging

anti-UV

anti-static

high-temperature/low-temperature resistance

toughening

rigidity

foaming performance

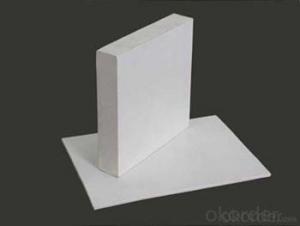

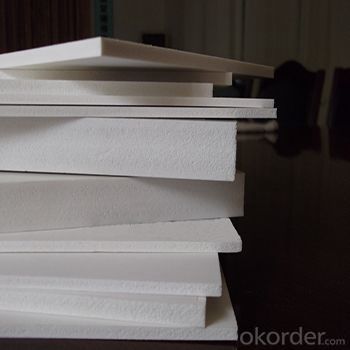

5. Pictures of PVC Foam Sheet

6.Pictures of Factory

- Q: i use type 6 plastic[the plastic containers that salads normally come in] as shrink plastic to make shrinkydinks.but i was wondering is there another place to purchase it other than shrinkydinks?easy 10 points.

- Heres okorder

- Q: How long do plastic sheets last?

- The lifespan of plastic sheets can vary depending on factors such as the type of plastic, quality, exposure to sunlight, and usage. However, on average, plastic sheets can last anywhere from a few years to several decades.

- Q: Can plastic sheets be used for awnings?

- Yes, plastic sheets can be used for awnings.

- Q: I was wondering if it was possible to run a plastic binder cover (like the kind you use with a comb binding machine) through my printer? I'm not sure if the ink would even actually stick to it... or if it might even melt in my new printer? I have a new Kodak ESP3... so I don't want to mess it up! Anyone know? I know you can buy clear sheets made for the inkjet printers... but I didn't know if these were different... Thanks in advance.

- the binder covers a to slick for the ink to stick to. the overhead clear plastic printable sheets are a bit thin for use as covers. There are Thermal plastic sheets that will take printing...ask some graphic engineer...they use it for overlays on plans.

- Q: Are plastic sheets safe for children?

- Plastic sheets can be safe for children as long as they are made from non-toxic materials and have no sharp edges or small parts that could pose a choking hazard. It is important to choose the right type of plastic sheet and supervise children during use to ensure their safety.

- Q: Are plastic sheets resistant to scratching from tools?

- Yes, plastic sheets are generally resistant to scratching from tools. However, the level of resistance may vary depending on the type and quality of the plastic used.

- Q: Can plastic sheets be used for DIY face shields?

- Yes, plastic sheets can be used for DIY face shields. They provide a transparent barrier that helps protect the face from respiratory droplets and other contaminants. However, it is important to ensure that the plastic sheet used is of sufficient thickness and clarity to provide adequate protection. Additionally, proper sanitization and cleaning of the face shield should be practiced to maintain hygiene.

- Q: Can plastic sheets be used for DIY cutting boards?

- No, plastic sheets are not suitable for DIY cutting boards as they are prone to scratches and can harbor bacteria. It is recommended to use materials specifically designed for cutting boards, such as wood or food-grade plastic.

- Q: It's flat, like paper, but with a layer of plastic over top of it that has grooves into it that refracts the image printed on the paper. You used to get them in cereal/crackerjack boxes, or printed on a child's plastic ruler, or sometimes even the cover of a book would have them. Depending on the angle that you hold them, you see different images. You could tip them back and forth to produce a little 5 or 6 frame animation. Or some of them even let you see some basic 3D stereoscopic images. You don't need to wear 3D glasses or anything, it's just a flat thing.What's that technology called? I'm trying to find info about them and I don't know what they're called. Is there a company that will make them for me?

- You may be talking about a Fresnel lens which is flat but provides magnification. It consists of grooves in the plastic. You can see odd optical things when you bend it or look at it at an angle. You may also be talking about a polarizing filter which physically blocks some of the light waves and allows other light waves to pass thru. The grooves are too small to see. I suppose you could have a polarized Fresnel lens.

- Q: How are plastic sheets different from other materials like glass or metal?

- Plastic sheets are different from other materials like glass or metal primarily due to their composition and properties. Unlike glass, plastics are synthetic materials derived from polymers, making them more flexible, lightweight, and less brittle. Plastic sheets are also transparent or translucent, similar to glass, but are less prone to shattering. In contrast to metals, plastic sheets are non-conductive, have lower density, and offer better insulation properties. Additionally, plastics are generally more cost-effective, easier to mold, and can be manufactured in a wide range of colors and textures, making them highly versatile in various applications.

Send your message to us

Plastic Sheets - PVC Free Foam Board / PVC Sheet PVC Celuka Moulding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords