PVC Ceiling Panel Lamination Groove Ceiling Tiles

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 550000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Panel Description

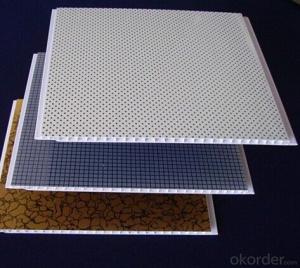

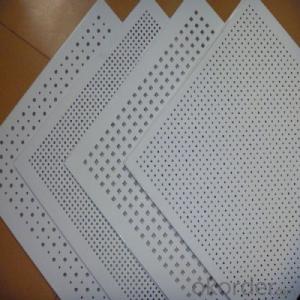

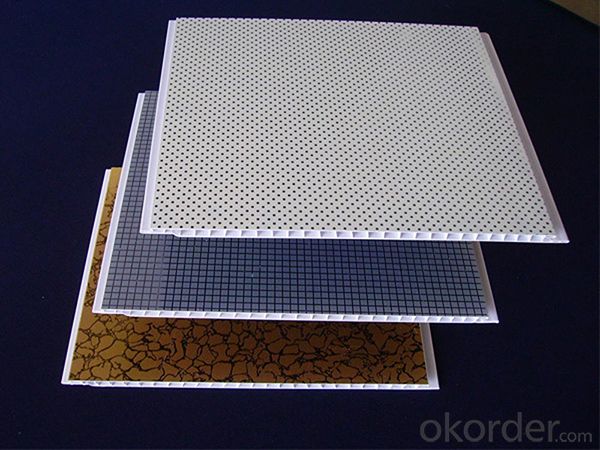

Specification

1)Width:100mm,200mm,250mm,300mm,380mm,595mm

2)Thickness:5mm,6mm,7mm,7.5mm,8mm,9mm,10mm

3)PVC content:30%-80%,as your request.

Feature

1,Easy installation ,surface is smoothness ,flatness, without gap when concatenated.

2,It can be processed by drilling ,sawing, nailing.

3,High intensity, high strength, not easy to deformation, resist erosion, sound insulation,

waterproof, fireproof, aging-resisting, durable

4,Interior decoration for ceiling. Easy clearing, heathy and enviroment.

Characteristic of PVC panel:

Fireproof : Self-fire extinguishing, non-flammable , fire and inflaming retardant.

Waterproof (damp-proof): Resistance to weather/ special chemicals; Waterproof / Washable.

Rustproof (resist erosion) : It is impenetrable by insects or termites, and won' t rot or rust.

Heatproof : Good high temperature impact performance .

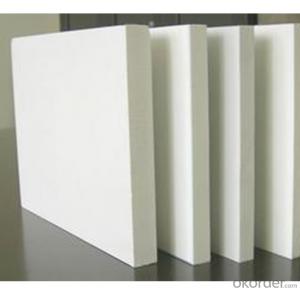

High intensity : The excellent rigid and superior impacted surface is without any peeling.

Anti aging : Good aging resistance , durable in all mechanical characteristics .

Quality : Hard quality, high intensity and sheen , fadeless , environmental friendly

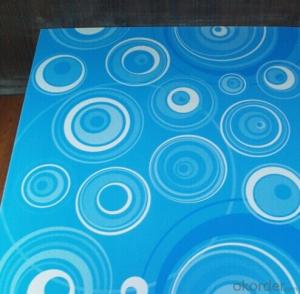

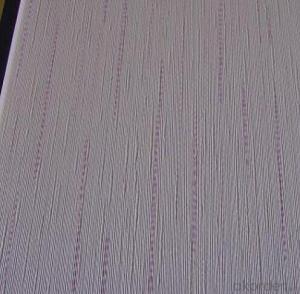

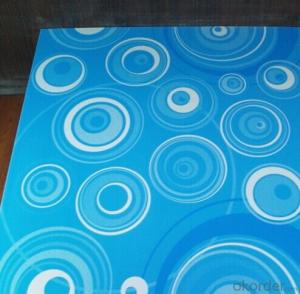

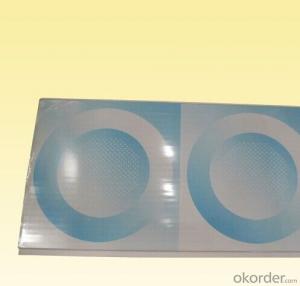

Design : The variety of colors and patterns .Natural wood (marble) grain: showing authentic wood

Easy setting : Light in weight , the simple and fast installation can save a lot of time and manpower

Other : Easy to be cut, drilled, nailed, sawed, and riveted. DIY is all right;

Quick maintenance and no need of painting;

Good resistance fixations.

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures

- Q: Whenever we run hot water in the kitchen (faucet or dishwasher), a loud knocking noise comes from the PVC pipes in the basement. It seems to be coming from the main drain pipe which is about 3 or 4 inches in diameter, and it knocks right along the ceiling joists. After a few minutes the knocking stops. Any suggestions?

- it sounds to be a loose system but what you are asking sounds like contraction and expanding from hot water and then it cools off and it goes back to normal, it creeks. its plastic you can insulate it might help

- Q: I have a blank PVC gusset plate, plastic material. I want to buy some heat transfer film transfer up, but do not know what equipment through the heat, the general plane thermal transfer machine can it? I am worried that the plastic buckle into the thermal transfer equipment will heat deformation. Please recommend a transfer on the plastic equipment, thank you! Do you buy some blank thermal transfer film through the printer can be printed after the thermal transfer to plastic up?

- Civilian 1610uv printer, printing format 160cm * 100cm, four DX5 nozzle or 5 gs508 nozzle configuration, price 7w-15w. Printing speed of 4-15 square meters / hour. Printing areas are leather, tiles, etc., high-precision, high-speed shop shop equipment. Large 2513 universal printer, printing format 250cm * 130cm, four DX5 nozzle or 4-14 gs508 nozzle configuration or 4-14 gs1024 nozzle configuration, price 16w-60w. Printing speed of 15-80 square meters / hour. Printing areas are glass sliding doors, backdrop, advertising materials, high-precision, high-speed factory batch production equipment.

- Q: Can the knives cut the PVC board? Murphy meat grinder commercial and home where to have to buy?

- PVC board is PVC as raw material made of cross-section for the honeycomb mesh structure of the plate. Is a vacuum plastic film, used for all kinds of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foam board.

- Q: PV board, PVC board material properties

- If you refer to the polymer chemical industry. I have not heard of PV, is polyvinyl alcohol? If so, this material is not suitable for high physical properties of the material, because I remember it in the MSDS described in the air heated to above 100 ℃ slowly discoloration, brittle. Heated to 160 ~ 170 ℃ dehydration etherification, loss of solubility, heated to 200 ℃ began to break down. More than 250 ° C into a polymer containing conjugated double bonds, is a water-soluble polymer material, widely used in low viscosity glue, but also the use of fiber vinylon. PVC, then, that is, polyvinyl chloride, very common, uh. Chemical stability, it can be used for the production of anti-corrosion pipes, pipe fittings, oil pipeline, centrifugal pumps and blowers. Polyvinyl chloride board is widely used in the chemical industry to produce a variety of storage tank lining, building corrugated board, doors and windows structure, wall ornaments and other building materials. Because of electrical insulation performance, in the electrical, electronics industry, for the manufacture of plugs, sockets, switches and cables. In daily life, PVC is used in the manufacture of sandals, raincoats, toys and artificial leather ~ we now use PVC pipe, because the iron pipe is easy in the winter by the risk of ice, but if you use the plastic belt or Plastic film is PVC material, do not use Oh, PVC production of stabilizers are added to the highly toxic chemicals, u just just talk about the landlord would like to know more about the knowledge, then I can explain

- Q: PVC board, ABS board, KT board What is the difference between ~ ~ What are the purposes?

- PP Polypropylene PVC PVC EPS polystyrene ABS acrylonitrile / butadiene / styrene copolymer PC Polycarbonate PE polyethylene KT board is a light decorative plate, the actual is the two sides affixed with smooth paper foam board, generally used for display panels or as a temporary structure of the partition. KT board can be used for display board production, screen printing, etc., with KT board produced by the beautiful display panels, convenient and light, affordable. (But according to multi-feedback: KT board like a bubble, with a long time will be variant, the proposed use of organic board) KT board color: red, white, yellow, green, gray, blue, black. Two kinds of KD board: one is "enhanced anti-foaming KD board", flatness is good, hardness is strong. Applicable to advertising display, especially for large-scale pictorial inkjet produced a variety of board, he is the best cold plate KD plate. The second is the "economic anti-blister KD board", mainly for the back of the frame, screen printing and silk screen after the POP advertising production. It is the best KD plate to bite the market.

- Q: At present home decoration used in white, beige panels have those? Type with PVC board?

- Similar to PVC is a polymer-free paint panel

- Q: Pvc foam board and wood-plastic plate difference?

- Pvc foam board and wood-plastic plate difference? The former is the gas plate, which is a solid plate; the former can not hollow, the latter can!

- Q: Pp board and pvc board which is expensive

- PP board than the price of expensive PVC board, but the quality of the service life of course, will be longer.

- Q: Is there a fitting, or a way, that will both convert a pipe from PVC/CVPC to copper and reduce the size?I have old copper pipes that continually spring leaks. These pipes run along the basement ceiling which are easily accessible. I am planning on leaving the copper pipes that come off the main lines and go up into the house to the faucets.I am planning to replace the main pipes with PVC/CPVC. The main lines are one inch and the copper pipes being left are a half inch.My question is, is there a fitting or a way, that will both convert the pipe from PVC/CVPC to copper and reduce the pipe from one inch to a half inch.Thank you

- Copper female adapter to plastic male adapter. To reduce size use two reducing couplings, 1 to 3/4, then a 3/4 to 1/2. You may have have trouble finding a 1 to 1/2 reducing coupling. You might find a 3/4 to 1/2 reducing bushing, so you won't need a short piece of 3/4 pipe.

- Q: Pvc buckle board, installed smallpox, the specific steps, must be detailed, to DIY Kazakhstan

- Hello, the following began to hang pvc buckle board ceiling. Material; pvc buckle plate, pvc trim corner, card main dragon, deputy dragon Tools; impact drill, glass gun, glass glue (porcelain white) self-tapping screws, screwdriver, 6 PCT top burst, 8% impact drill, 6% screw, 6% nut, Start construction; first set a point in the porcelain wall, see the ceiling hanging high, and then hit the water, in the pvc trim corner sticking glass glue, and then stick in the flat water line, the angle and the outer corner is more trouble. And then side by side in the zeal hit 4 holes, (8% impact drill) installed 6% burst, remember to open the top. And then from the top of the ceiling to pvc trim angle, the height is 6% screw to cut the length of the cut in the 4 4 4 screw at one end of the twist nut, and now began to card on the main dragon, and then the deputy dragon Hanging out, so that the ceiling board ceiling out of the shelf.

Send your message to us

PVC Ceiling Panel Lamination Groove Ceiling Tiles

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 550000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords