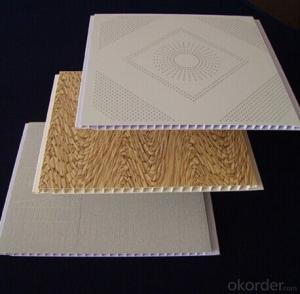

PVC Ceiling Heat Insulation Panel 59.5cm*59.5cm - PVC Building Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

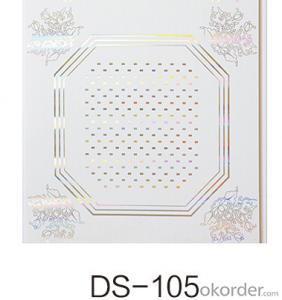

| Type: | Ceiling Tiles | Place of Origin: | China (Mainland) | Brand Name: | CNBM |

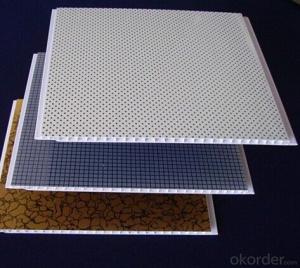

| Model Number: | YPHJ-771 | Function: | Fireproof, Heat Insulation, Moisture-Proof, Mould-Proof, Smoke-Proof, Sound-Absorbing, Soundproof, Waterproof | Feature: | Artistic Ceilings, Honeycomb Ceilings, Integrated Ceilings, Perforated Ceilings |

| Ceiling Tile Shape: | Square | Ceiling Tile Type: | PVC Ceilings |

Packaging & Delivery

| Packaging Details: | pvc films |

| Delivery Detail: | 15days after received customer 30% deposit |

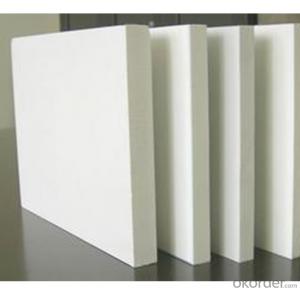

PVC CEILING PANEL

1.Product Details

Place of Origin: Zhejiang China (Mainland) Brand Name: PVC Panel Shenao

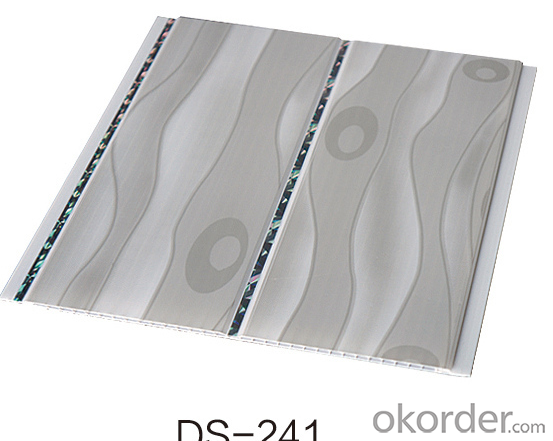

PVC Panel Name: PVC Ceiling PVC Panel PVC Panel Use: For Ceiling

PVC Panel size: 6mm/7mm/8mm*20cm PVC Panel Material: PVC

PVC Panel Colors: Many different colors PVC Panel Thickness: 7mm

PVC Panel Typle: Flat PVC Panel Quality: 50%PVC

PVC Panel Loading: 20'ft/40'HQ container PVC Panel Finish: Printing

2.Detail form:

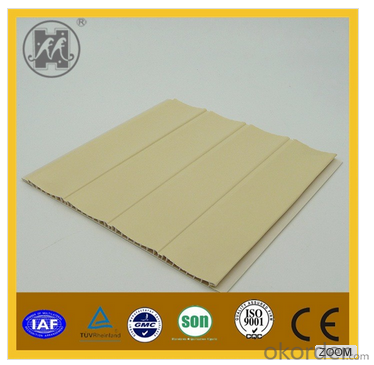

| Thickness | 5MM/5.5MM/6MM/7MM |

| Width | 200MM |

| Length | 5800MM/5950MM |

| Finish | Prining/High glossy/Transfer |

| Typle | Flat/groove in middle |

| Quality | high |

| Loading | 20'ft/40'HQ container |

| Materia | PVC |

| Use | For wall or ceiling |

| Certificate | "ROHS""."ISO9001:2000" ."brand for china building line" |

| Weight | 1.8kg,2.1kg,2.3kg,2.5kg,2.75kg,3kg,3.12kg |

| Fetures | wearing resistence, water proof, flame retarding, aging resistence,smoothness,flatness,moth-proof. |

| Proof | light in weight and easy to install |

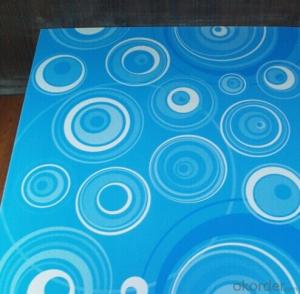

| Colors | Hundreds of colors available for surface treatment. |

| Payment | T/T |

| MOQ | 3000SQM |

| Delivery Time | 15 days after the received deposit |

| Packing | 10pcs/bundle,Shrink film,Cartone |

| Port | Shanghai Port |

3.PVC Panel Specification:

(1Thickness:5mm,5.5mm,6mm,7mm,7.5mm,8mm,8.3mm,8.5mm,9mm,9.5mm,12mm.

(2)Width:10cm,16cm,20cm,19cm,25cm,30cm,60cm

(3)Length:as per customers requirements

(4)PVC%:40%,45%,50%

(5)Colours and patterns:hundreds of colours and patterns for you to choose,or according to your specific designs.

4.PVC Panel Application:

(1)Household ornament:wall and ceiling of indent independent housebathroom or kitchen.

(2)Public and management place:toilet of building and hall.

(3)Common office:ceiling of business place.

FAQ

· Can we make an OEM order?

o We can offer or supply goods as customers' requirements.

· How can I get some samples? Free or not?

o We can send some normal samples, absolutely free.

· How does your factory do regarding quality control?

o "Quality is priority." We always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ISO9001 , SGS authentication, CE for Europe, etc.

- Q: PVC sheet and PVC coil What is the difference, what are the advantages and disadvantages?

- PVC sheet flooring Advantages: simple construction; construction personnel requirements are not high; construction speed; material loss is small; with UV treatment layer composite sheet flooring stain resistance, abrasion resistance, good antibacterial; personalized pattern laying easy, changing; Anti-indentation, sound-absorbing effect is good; environmental protection does not contain formaldehyde; floor anti-skid performance; floor damage easy to replace; floor light weight can effectively reduce the load of the building; fire performance B1 level. Defects: floor elasticity without coil floor is good; floor seams and more need to always waxing maintenance; fear of surface water immersion; floor size and poor stability; homogeneous body sheet stain resistance, wear resistance, Poor impact. Scope: sheet flooring is generally suitable for shopping malls, supermarkets, corridors, corridors, home, offices, halls, schools and other places. PVC sheet flooring Advantages: floor price selection range; wide range of application; anti-pollution, acid-resistant, good maintenance, easy maintenance; flexible, non-slip performance; wear, antibacterial, not moth, mildew; Will be affected by temperature, moisture deformation; safety, environmental protection does not contain formaldehyde; noise noise, foot comfort; color, rich patterns, fully meet the individual design needs; fire performance B1; light weight, reduce the building load, floor seams less. Defects: high construction requirements; fear of cigarette burns; floor damage is not easy to replace. Scope: schools, hospitals, offices, shopping malls, cars, ships, subways, trains, home, laboratories, laboratories, research, stairs, nursing homes, libraries, theaters and other fields

- Q: how to build cat cages out of PVC pipe?

- Pvc Cat Cage

- Q: Pvc board and rubber contact why fade?

- Production of PVC sheet on the use of toxic compound lead salt more stable, more cost-effective Baohua PVC efficient heat stabilizer patent series

- Q: Pvc board can not be posted on the wallpaper, can be used to how long

- According to the actual situation

- Q: In the test results are good, the school would like to promote a, please master advise, get hold of a PVC board to write what both connotation, and there is no shortage to improve their reputation.

- Highlight the highlights of the school test, compared with previous years of progress;

- Q: PVC board paint blistering

- Due to the high temperature of the bubble. 1, the product is ready to be placed after cooling for two to three days, not sun exposure or baking at high temperatures. 2, blistering, paint is a common common defects. Which is sometimes dry, sometimes liquid. Foaming is large and small, shape hemispherical. The size is usually related to the strength of the adhesion of the substrate, or the bond strength between the coatings, and the pressure within the bubble or blister 3, if the bubble continues to the substrate: should find ways to eliminate the source of moisture, repair loose caulking glue, consider installing the exhaust fan, remove the bubbles. If the bubble does not extend to the substrate: the bubbles should be scraped off, and then polished, any must be on the primer, and finally re-coating high-quality paint.

- Q: VC plastic buckle the corners of the corners is how fixed to the wall of the buckle is how and cords connected to the light steel keel and gypsum do cut off the light steel keel is how and the wall ...

- Light steel keel sub-station dragon and Wolong. Wolong before the installation of the first hammer with a hammer, playing wooden needle, and Wolong fixed, and then install the station dragon, and clamp with a good fit.

- Q: Pvc stone floor with hot water bubbles after the UV layer can be torn from the floor, and then you can smell the irritating smell, the business that no formaldehyde, but I think this taste UV layer is certainly sticking up and not hot The

- No. Pvc floor from the structure of the main multi-layer composite and homogeneous through-heart and semi-homogeneous body type 3. The so-called multi-layer composite PVC floor is that it is a multi-layer structure, generally from 4 to 5 layers of laminated structure, generally wear-resistant layer (including UV treatment), printing film, glass fiber layer, Foam layer, grass-roots level. UV treatment is the use of epoxy resin for surface reinforcement in a way that can play anti-pollution and effective absorption of ultraviolet light, enhance wear resistance, delay product aging and easy to clean the role.

- Q: Acrylic PVC organic board What is the difference between these three materials What is the difference

- Acrylic 1. Transparent high, light is not easy to deformation, good guide optical rotation. 2. PMMA difficult to fire, can slowly burn. 3. Unsuitable alcohol, ketone, alkali, soluble in aromatic hydrocarbons, oxidized hydrocarbons (trioxide can be used as a binder). 4. Easy to shape, size and stability. 5. Impact resistance and surface hardness are slightly worse, easy to rub the price is very expensive PVC is very soft ... can be the same as the paper folded 2. and acrylic than ... acrylic is very easy to rotten 3.PVC will not rotten ... Organic board 1. partial yellow .. there are dregs .. material surface potholes .2. Thickness uneven .... he and acrylic like .. also known as advertising board ... very cheap

- Q: In the home pvc plastic buckle ceiling how to get Dad to use pvc plastic buckle board in the kitchen ceiling, did not get, do not know how to get, should pay attention to what, how to ceiling? Want to know friends help, thank you

- But for a person who has never done it, I am afraid that the completion of these work is still a bit difficult, so in this proposal: find a carpenter to help you as a good master.

Send your message to us

PVC Ceiling Heat Insulation Panel 59.5cm*59.5cm - PVC Building Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords