Heavy Gauge PVC Ceiling - Weeds Red Wine Laminated Panels in Kenya

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

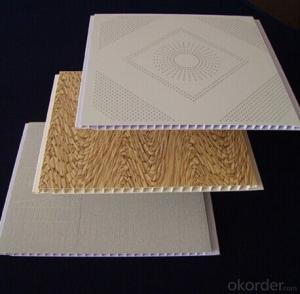

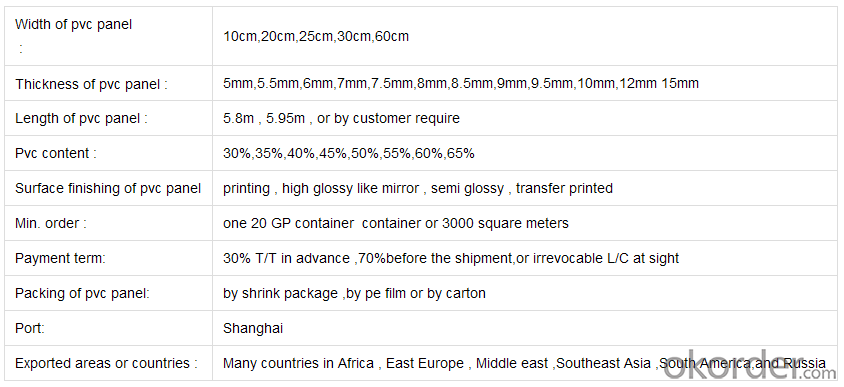

PVC ceiling panel-Lamination

size:250mm*7mm/8mm/9mm

weight of pvc panel:2.3 to 4kg/sqm

MOQ:20GP

lead time:10 days

Product Advantages:

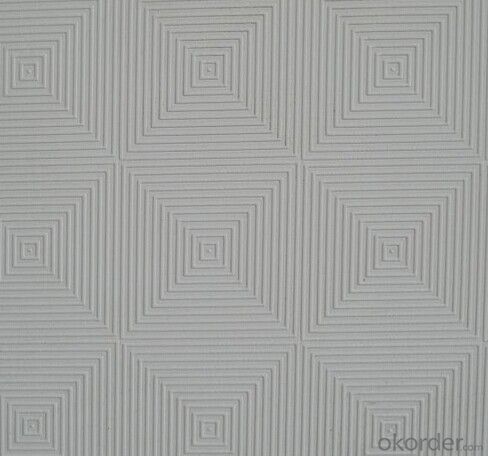

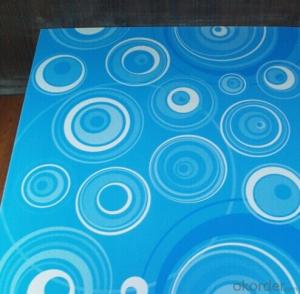

Printing PVC panel, decorative PVC panels for wall and ceiling:

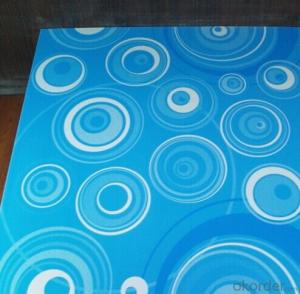

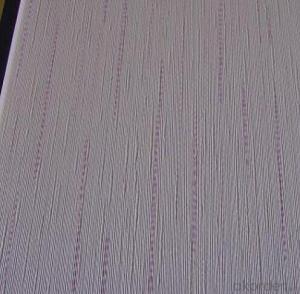

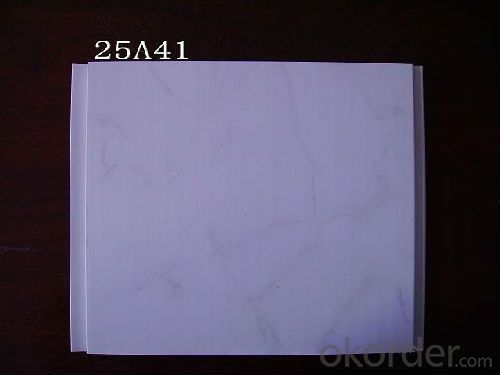

1. Rich color design, nice appearance

2. Widely used for indoor decorative

3. Easy to install and clear

4. Soundproof, waterproof, fireproof

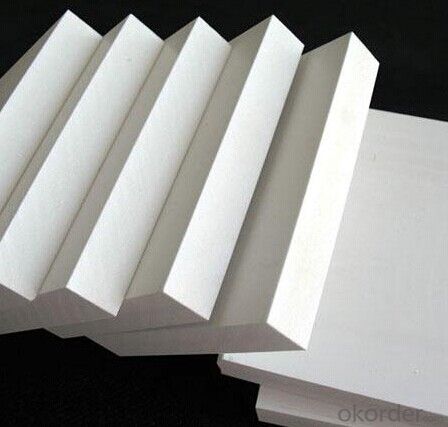

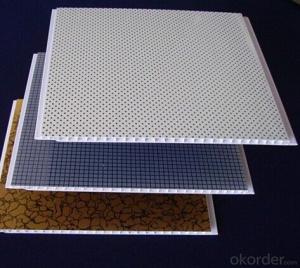

Shape of PVC panels:

1. Surface is flat

2. With a groove in the middle

3. With wave on the back of the panels

Different surface process:

1. Normal color printing

2. Film transfferred color printing

3. Laminated PVC panel.

4. Common glossy or high glossy

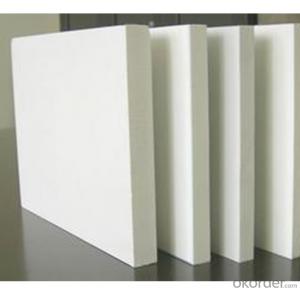

Main Product Features:

1) The variety of colors and patterns

2) High intensity, resist erosion, anti aging

3) Fireproof, waterproof, environmental friendly

4) Easy setting and cleaning

PVC panel application:

Widely used for indoor decorative, such as Hotels, commercial buildings, hospitals, schools, cooking rooms, washing rooms etc.

Product Specifications:

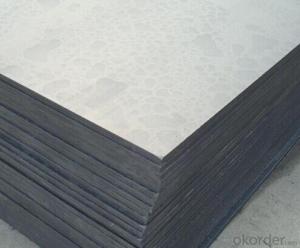

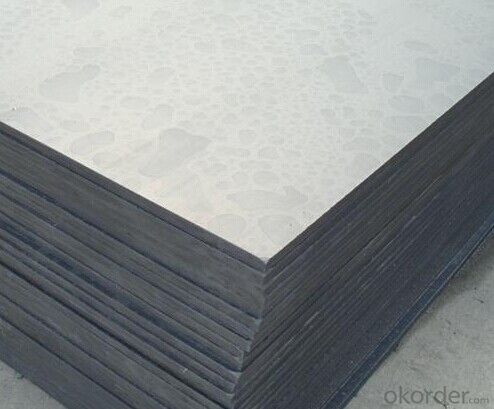

Images:

- Q: What is the difference between steel and PVC gussets?

- Steel, PVC, aluminum plate is three different materials, steel and steel doors and windows is almost, PVC is the lowest level of anti-aging plastic, aluminum plate is relatively thin aluminum plate anti-aging degree is the best. Price and quality level is proportional to, PVC two, thirty-one square, about 40 square meters of steel and aluminum buckle in a hundred or so a square.

- Q: PV board, PVC board material properties

- PVC used in the manufacture of sandals, raincoats, toys and artificial leather, etc. ~ Our home now use PVC pipe, because the iron pipe is easy to suffer from the risk of ice in the winter, but if you use plastic or plastic wrap is PVC material if

- Q: Pvc drainage board construction process which

- Clean up the laying of the scene of garbage, cement leveling, so that the scene is not obvious convex, outdoor garage roof and roof garden need to have 2-5 ‰ of the slope.

- Q: Sun room,studded partition over the windows, pvc on the exterior. Losing heat? What can I do? Tiled roof?

- You could try painting your tiles with a paint that will help to insulate the tiles but i reckon old mate's right , you gotta get some batts in the ceiling AND walls . Just check which is going to be easier to remove the inside skin or the outside skin. If it's fibro on the outside thats what i would do. It's worth while getting a no obligation quote and seeing what the so called experts think they can do to help keep in the heat. I would also get a local handyman out of the paper and get his thoughts cos chances are he has come across similar problems before and he will probably be cheaper than what you think...

- Q: What is the difference between acrylic and PVC?

- Acrylic is an important thermoplastic, with good transparency, chemical stability and weatherability, easy to dye, easy processing, beautiful appearance, in the construction industry has a wide range of applications. Plexiglass products can usually be divided into casting plates, extruded plates and molding compounds. PVC board is PVC as raw material made of cross-section for the honeycomb mesh structure of the plate. Is a vacuum plastic film, used for all kinds of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries.

- Q: With the area and thickness of the KT board and PVC board which is more expensive?

- Pvc also has a very cheap, that is, the density of the foam is not high. Kt board also has a high density, more expensive. This is generally very rare. ? Ordinary common pvc board expensive

- Q: The meaning of PVC board

- PVC board is PVC as raw material made of cross-section for the honeycomb mesh structure of the plate, is a vacuum plastic film. For all types of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC, according to the production process can be divided into PVC leather foam and PVC free foam board.

- Q: I recently used PP board (non-PVC board) to do a turtle pool, but in the paste when found with hot melt adhesive anyway will be leaking, has been repeated several times, but also with the screw

- Joint with glass glue, or with tin foil paste the place where the leakage and then bonding

- Q: Is pvc board insulator?

- Seemingly no absolute insulator!

- Q: Pvc board to do the props hard, I want to do cos props

- PVC can be divided into: general-purpose PVC resin, high degree of polymerization PVC resin resin, cross-linked PVC resin. General type PVC resin is formed by polymerization of vinyl chloride monomer under the action of initiator. High polymerization degree PVC resin resin is formed by polymerization of vinyl chloride monomer under the action of initiator; high degree of polymerization refers to vinyl chloride monomer Polymerization resin is added in the polymerization system. The crosslinked PVC resin is a resin obtained by adding a chain extender in the vinyl chloride monomer polymerization system. So PVC made of props or have a certain degree of hardness, tube network prompts you: in the wear must be careful not to hurt the skin

Send your message to us

Heavy Gauge PVC Ceiling - Weeds Red Wine Laminated Panels in Kenya

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords