PVC Blue Smooth Cable Ties Insulation Tape for Air Conditioner

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 10000000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Blue Smooth Cable Ties Insulation Tape for Air Conditioner

1.Structure of PVC Blue Smooth Cable Ties Insulation Tape for Air Conditioner Description:

PVC Blue Smooth Cable Ties Insulation Tape for Air Conditioner is designed for Air conditioning and used for HVAC system. Air conditioning tie: general and domestic brand air-conditioning manufacturer for cable tie. We can support you with different color like grey and white or blue

2.Main Features of PVC Blue Smooth Cable Ties Insulation Tape for Air Conditioner:

our Air conditioning tie with good and environmental quality of the products for the customer design research and development of different types, different colors and different quality of air conditioning products.

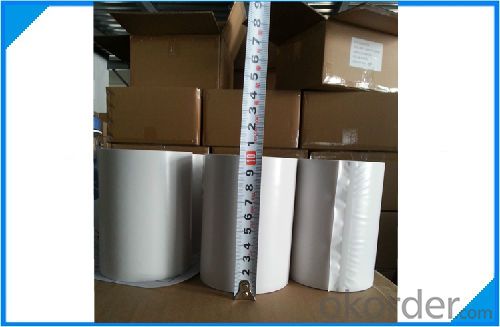

3. PVC Blue Smooth Cable Ties Insulation Tape for Air Conditioner Images

4. PVC Blue Smooth Cable Ties Insulation Tape for Air Conditioner Specification

0.2 mm * 50 mm * 20 m (thickness * width * length)

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers Commonly

- Q: Is it safe and effective to use aluminum foil facing material for wrapping food when preparing for freezing?

- <p>Yes, you can use aluminum foil facing for wrapping food for freezing. Aluminum foil is a good conductor of heat and provides a barrier that helps prevent freezer burn. It is also non-toxic and does not impart any taste to the food. Ensure the foil is tightly wrapped around the food to maintain its freshness and protect it from air exposure. However, it's important to note that aluminum foil is not microwave-safe, so if you plan to reheat the food, you should transfer it to a microwave-safe container before heating.</p>

- Q: This question asks for a comparison of the differences among different types of plastic containers.

- <p>Plastic containers vary in material composition, durability, temperature resistance, and intended use. HDPE (High-Density Polyethylene) is sturdy and good for detergent bottles and milk jugs. LDPE (Low-Density Polyethylene) is flexible and used for plastic bags and film. PET (Polyethylene Terephthalate) is recyclable and used for water bottles and food containers. PVC (Polyvinyl Chloride) is durable but not food-safe due to potential leaching of harmful chemicals. Polypropylene is resistant to heat and acids, making it suitable for microwave-safe containers. Polystyrene is lightweight and clear but not microwave-safe and can release styrene, a harmful chemical, when heated. Each type has specific uses and properties that make it suitable or unsuitable for certain applications.</p>

- Q: Can aluminum foil be shaped into a roasting rack?

- <p>Yes, you can create a makeshift roasting rack using aluminum foil. To do this, take two long sheets of aluminum foil and fold them back and forth to create a series of parallel ridges. These ridges will provide support for your roast while allowing air to circulate underneath. Place the folded foil on a baking sheet, spacing the ridges evenly apart to create a grid-like pattern. Your roast can then be placed on top of this foil 'rack' for cooking. This method is a simple and effective way to elevate your food for better heat distribution and crisping.</p>

- Q: Explain how to best utilize aluminum foil facing in the preparation of a sandwich.

- <p>The best ways to use aluminum foil facing in a sandwich include: 1) Wrapping the sandwich to keep it fresh and prevent it from drying out, especially when storing for later. 2) Using it as a makeshift 'grill' by placing the sandwich between two sheets of foil and toasting it in a panini press or on a stovetop for a crispy exterior. 3) Creating a foil pouch by sealing the sandwich in foil, which can be used for cooking sandwiches in an oven or on a campfire, keeping the ingredients moist and tender. 4) Using foil to press down on the sandwich while grilling or toasting, ensuring even heat distribution and a uniform texture. Always ensure the foil is food-safe and does not come into direct contact with the sandwich's fillings to avoid any potential contamination.</p>

- Q: This question asks for a comparison between aluminum foil facing and other types of metal foils, highlighting their differences.

- <p>Aluminum foil facing is distinct from other metal foils due to its specific properties. It is lightweight, highly reflective, and offers excellent heat conductivity, making it ideal for insulation and cooking applications. Unlike other metal foils, aluminum foil is non-toxic and can be safely used in food packaging and preparation. It is also corrosion-resistant and has a lower melting point compared to metals like steel or copper, which affects its usability in various industries. Additionally, aluminum foil is more affordable and widely available than some other metal foils, contributing to its popularity in everyday use.</p>

- Q: What are the various materials used as facings for aluminum foil, and how do they differ from one another?

- <p>Aluminum foil facing materials are used in construction and insulation to provide a barrier against air and moisture. The different types include: 1) Kraft paper facing, which is a strong, absorbent paper used for general purposes; 2) Glassine facing, a thin, glossy paper with good water resistance; 3) PE-coated facing, where a layer of polyethylene is applied for enhanced water resistance; 4) Aluminum foil facing, which is a thin layer of aluminum for superior barrier properties; 5) Silicone-treated glass fabric, offering high-temperature resistance and used in high-performance applications. Each type has unique properties affecting their use in various applications.</p>

- Q: This question asks for the optimal methods of preserving leftover food using aluminum foil.

- <p>The best ways to store leftovers using aluminum foil involve ensuring the food is cool before wrapping, covering the entire dish tightly, and sealing the foil properly. First, let the leftovers cool down to room temperature to prevent condensation. Then, wrap the dish completely with aluminum foil, making sure to cover the edges and corners to avoid air exposure. For added protection, you can double-wrap the dish. Seal the foil by pressing the edges together firmly. Store the wrapped leftovers in the refrigerator or freezer, depending on how soon you plan to consume them.</p>

- Q: Is it possible to recycle aluminum foil facing multiple times? If yes, what is the process involved?

- <p>Yes, aluminum foil facing can be recycled multiple times. The recycling process involves collecting and sorting aluminum waste, which is then shredded or crushed. The material is melted in a furnace at high temperatures, and the molten aluminum is poured into molds to form new products. This process can be repeated indefinitely without losing the quality of the aluminum, making it one of the most recycled materials globally. The recycling of aluminum saves energy and reduces the environmental impact compared to producing aluminum from raw materials.</p>

- Q: This question asks about the various types of aluminum foil facing used in construction and insulation materials.

- <p>Aluminum foil facing is used in various applications, including insulation and construction materials. The different types include: 1) Plain Foil Facing, which is a smooth, uncoated aluminum foil; 2) Coated Foil Facing, which has a protective coating applied to one or both sides; 3) Laminated Foil Facing, where aluminum foil is bonded to other materials like polyester or polyethylene; 4) Embossed Foil Facing, featuring a pattern or texture on the surface for added strength or aesthetic purposes; and 5) Reinforced Foil Facing, which incorporates additional materials to enhance durability and tear resistance.</p>

- Q: What are the particular criteria or considerations when choosing aluminum foil facing materials?

- <p>When selecting aluminum foil facing, specific requirements include the foil's thickness, which affects durability and insulation properties; surface finish, which can impact heat reflection and aesthetics; and the type of adhesive used for bonding, which should be resistant to heat and moisture. Additionally, the foil should have good barrier properties to prevent moisture and air infiltration, and it should be compatible with the substrate materials to ensure a strong bond. Compliance with safety and environmental standards is also crucial.</p>

Send your message to us

PVC Blue Smooth Cable Ties Insulation Tape for Air Conditioner

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 10000000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords