Push-pull Steel Prop 2.5M-4.5M Q235 Steel Prop Standard EN1065 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

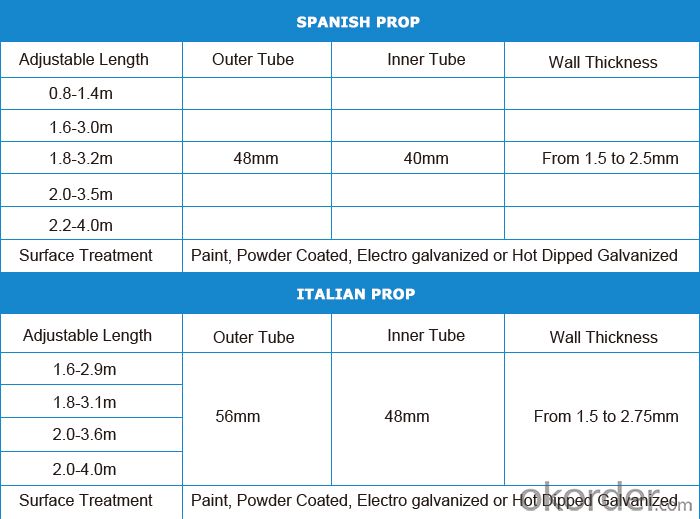

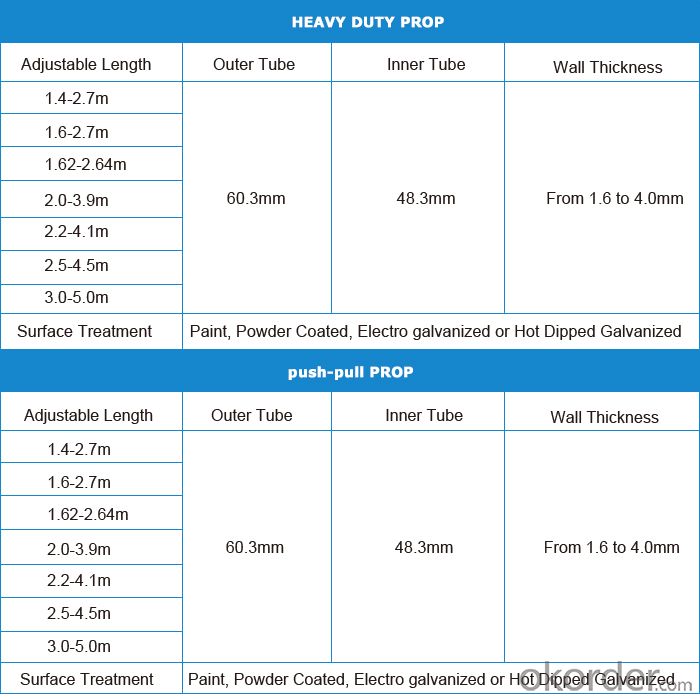

Quick Details of Push-pull Steel Prop 2.5M-4.5M Q235 Steel Prop Standard EN1065

Material :Q235 carbon steel

Surface treatment :painted/electro-galvanized/power-coating/hot dipped galvanized

Standard: EN1065

Thickness :1.6mm-3.0mm

Descriptions of Push-pull Steel Prop 2.5M-4.5M Q235 Steel Prop Standard EN1065

Our steel prop is a very Economical & practical & simple & easy installation bracing member with very high bearing capacity.

The steel props are very good vertical support suitable for various shaped slab formworks and popularly used in vertical structure support system. 4000 tons annual output.

Our steel prop used as a formwork is with very high bearing capacity.

Steel prop's vertical load capacity (within 4 meters length) can reach 10 KN.

Nuts are strictly manufactured according to national standard and with 10 tons load capacity.

Basic load capacity ≥15KN tested by national authorized organizations.

Shortening working hours & high efficiency

Firm structured props with high strength bearing capacity perfectly resisted the external shocks.

Galvanized prop surface process

Practical & Economical steel props make the buyers feel safe.

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: What are the functions and requirements of the masonry wall

- 6, vertical closure: from the second step to the fifth step, each step required in the outer row of pole side door set like baluster 1.00m high and block feet or to set up protective net, rod (net) and the vertical rod fastened; more than fifth steps in a protective railing, should all the safety fence or security legislation net; in the street or densely populated areas, should be from the second step, the safety fence or outside of all network security legislation.7, scaffolding erection should be higher than the top of the building or the operating surface of 1.5m or more, and add enclosure.

- Q: According to the standard set up double scaffolding scaffolding to the number of meters per square meter

- Once the calculation is qualified, you can according to the vertical distance

- Q: What are the characteristics of Pankou scaffolding

- Ottohelix Pankou scaffold has strong resistance to high temperature, not burning, bearing strength strong core strengths. To avoid any possible security risks, all customers as the basic starting point for the creation of ideas. In the construction process, to ensure the smooth passage of the system, the security of the future.

- Q: Cantilever beam type scaffolding can not exceed the maximum number of not married

- An overhanging canopy should be the pillars of the non overhanging balcony canopy may be concave balcony, may also be the pillars of support (pretty much before the home house) pick style balcony canopy should be the cantilevered balcony canopy is not that direct pick out in the post

- Q: Can anyone give a very brief description on all three scaffold scenes in The Scarlet Letter?

- oh dang u have to read that story too ! man i had to read it and watch the movie ! so boring. What grade are u in ?

- Q: i had my scaffold piercing done in the summer holidays and wen i went back to school (currently in my last year) they told me to take it out so i had to go back to the piercer. They changed the bar to two clear retainers in the holes so they wouldn't heal, now it hurts all the time and is red with a bubble on the top of my ear, any suggestions as to what i should do? :/

- try drying it out with sea salt soaks, tea tree oil, aspirin paste (crushed aspirin and water) , chamomile tea bag soaks !!! keloids are unpredictable , you can get them anytime from changing the jewelry early, irritation, bumping it on stuff or accidentally yanking it , and they will either stay or go away !!! you can prevent infections by cleaning the piercing regularly with anti bacterial soap and sea salt soaks , making sure to use clean hands when handling the piercing and not letting anyone touch the piercing

- Q: In the calculation of the bearing capacity of the scaffold, what is the axial force produced by the "N g2k" - the standard value of the component?The calculation formula for force rod scaffold N/ psi A+Mw/W = fWhere N=1.2 (Ng1k+Ng2k) +0.85*1.4 Sigma NqkThe specification of N g2k is explained in terms of the axial force generated by the standard values of the component fitting,It is how to understand, specifically refers to what? That is to say, what is the standard value of the component?Please master all trouble, thank you generous with your criticism!

- (3) the railings and retaining scaffold deadweight standard value (kN/m); the railings, bamboo amphipodsshouban baffle, the standard value of 0.15NG3 = 0.150 x 7 x 1.500/2 = 0.788 kN;(4) the load of the hanging safety facilities, including safety net (kN/m2); 0.005NG4 = 0.005 x 1.500 x 24 = 0.180 kN;

- Q: I know the ivy sort of glues itself to whatever surface with little sticky pads so that will take care of itself on the back of my house but can I use the existing Ivy for the wisteria to grab onto and climb up or will the wisteria be too heavy and pull the ivy down? I'd rather avoid having to build something for the wisteria to wrap itself around. Any suggestions? Thanks! : )

- No, ivy isn't that strong. One can easily unzip it from the walls. Wisteria is way too heavy for ivy. Plus you have the root competition down below. Ivy creates an incredible dense mat of roots , little grows with it. Wisteria would have quite a battle on its hands for root space and nutrients.

- Q: What is the service life of the mobile scaffolding accessories?

- In actual use, there are a lot of mobile scaffolding accessories because of deformation, and other reasons, resulting in a lot of scaffolding accessories are not easy to use, or even eliminated. Therefore, the overall life of about 5 years. Therefore, the use of mobile scaffolding accessories should pay attention to the maintenance, so that its useful life to get more, the value of the use of more perfect.

- Q: Which accessories are included in a movable scaffold

- Chinese now used in the steel pipe scaffold material made of steel tubular scaffolding, bowl button steel scaffolding, buckle disc scaffolding, socket type steel pipe scaffolding, scaffolding, ladder scaffolding, and every kind of the scaffolding, hanging scaffold and the scaffold steel pipe materials.

Send your message to us

Push-pull Steel Prop 2.5M-4.5M Q235 Steel Prop Standard EN1065 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords