Push-pull Steel Prop 1.6M-2.7M Q235 Steel Prop Standard EN1065 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

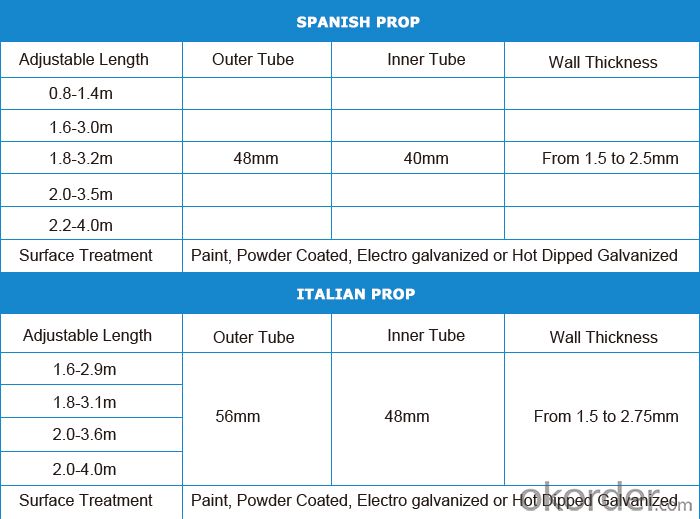

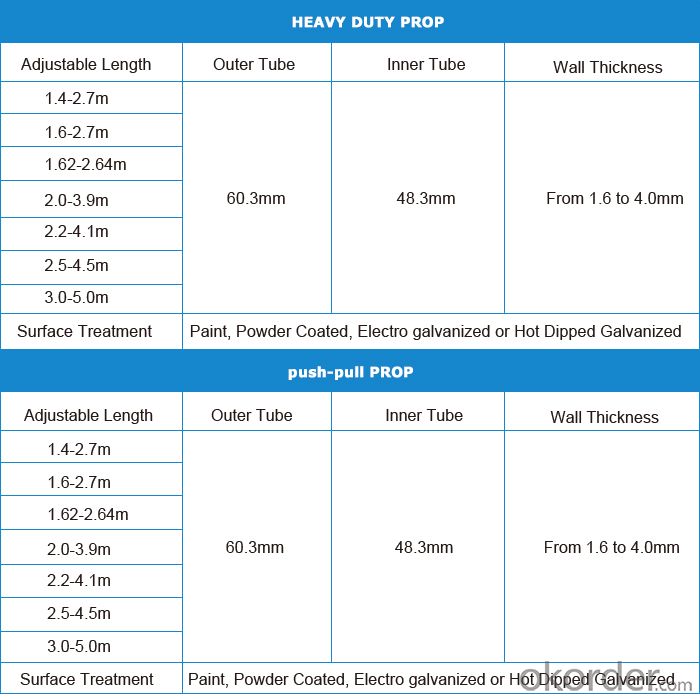

Quick Details of Push-pull Steel Prop 1.6M-2.7M Q235 Steel Prop Standard EN1065

Material :Q235 carbon steel

Surface treatment :painted/electro-galvanized/power-coating/hot dipped galvanized

Standard: EN1065

Thickness :1.6mm-3.0mm

Descriptions of Push-pull Steel Prop 1.6M-2.7M Q235 Steel Prop Standard EN1065

Our steel prop is a very Economical & practical & simple & easy installation bracing member with very high bearing capacity.

The steel props are very good vertical support suitable for various shaped slab formworks and popularly used in vertical structure support system. 4000 tons annual output.

Our steel prop used as a formwork is with very high bearing capacity.

Steel prop's vertical load capacity (within 4 meters length) can reach 10 KN.

Nuts are strictly manufactured according to national standard and with 10 tons load capacity.

Basic load capacity ≥15KN tested by national authorized organizations.

Shortening working hours & high efficiency

Firm structured props with high strength bearing capacity perfectly resisted the external shocks.

Galvanized prop surface process

Practical & Economical steel props make the buyers feel safe.

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: Latch type disc scaffolding accessories are national patent products?

- The utility model is mainly used for a light frame and a background frame of a large-scale concert Pankou, type multifunctional scaffold, the scaffold socket diameter of 133mm and thickness of 10mm disc, 8 hole disc, adopting 48*3.2mm, Q345A pipe master component, the vertical rod is in the pipe length of every 0.60m welding on a disc, rail connection using this novel and beautiful disk. The bottom with the connecting sleeve. The cross bar is made of a plug with a plug welded on both ends of the steel pipe.

- Q: i already found the force in rope 2 but im not getting the force in rope 1.

- The tension in the two vertical ropes must sum to 700N in order to balance the window washer. EDIT. In order to find the answer for each rope, I need to know how long the scaffold is and where the window washer is standing. EDIT. Taking moments about the end nearest to window washer. T1*3.044 = 298.6*1.522 + 700*1.51 ----> T1 = 496.54 N (2. d. p.) Taking moments about the other end. T2*3.044 = 298.6*1.522 + 700*1.534 ----> T2 = 502.06 N (2. d. p.) T1 + T2 = 496.54 + 502.06 = 998.6 = 700 + 298.6 as required.

- Q: What are the full house scaffolding specification

- Preparation of "full house scaffolding construction plan" according to the specification including but not limited to the following:1 "steel pipe scaffold fastener" (GB15831-2006)2 "technical code for safety of high level construction work" (JGJ80-1991)3 "technical code for safety of scaffold for building construction" (JGJ202-2010)4 "code for safety of steel tubular scaffold with couplers in construction" (JGJ130-2001)

- Q: Which kind of scaffolding is the most convenient and time-saving?

- 3, low cost (can speed up the construction schedule, shorten the construction period), large spatial scaffolding in the same condition, the new building quick dismantling scaffold material ratio of bowl type multifunctional scaffold, the same specifications of single member weight than the bowl type multifunctional scaffolding light.

- Q: there is also shrubs and trees planted on the base of the wall and 14 feet from it

- Scaffolding and Cherry picker is your best option.

- Q: I plan to have a scaffolding or industrial piercing soon, but don't know where to go.Any suggestions and could you include the prices?x

- Cost depends on the studio. It ranges from 20 to 45 pounds for each piercing, most common price is 25 pounds for each piercing, high quality titanium or stainless steel jewelry included. The industrial is 2 piercings in one so : 25 + 25 = 50 pounds, jewelry included.

- Q: Cells from an animal's muscles are processed with chemicals and they grow. The cells are transferred to a metal scaffold and are stimulated physically. In a few months, you have a big block of meat which can be ground and cooked. What do you have to add? Does this innovation mean the price of meat will become a very minor expense?

- Depends on how much it costs to stimulate the growth.

- Q: Right! I've heard from so many different people about this. Some say that you should never twist an industrial because it can damage the delicate newly healing skin cells. Others say that you must twist it to prevent the jewelry from healing attached to the skin and to be able to clean it properly.There really doesn't seem to be a definitive answer!My piercer has said not to twist it, so I haven't been, and I'm happy that the piercing is clean enough, etc. However I'm interested in whether any of you out there have found that not twisting it can damage it more than doing so.Thanks

- mine told me to twist it....i twist it like every day haha. nothing bad has happened

- Q: What are the common rules for calculating the amount of scaffolding works

- According to the wall masonry scaffolding (single) vertical projection area calculation with square metre.Scaffolding, without deduction of door and window opening, air ring, vehicle channel, deformation joint area. At the same time, the height of the same building is different, according to the vertical height of the building.

- Q: Specification and type of scaffold erection

- 4 the vertical pole of the scaffold, the size of the cross bar according to the specific use of the scaffold to determine the specific circumstances, but shall not exceed the following values:Horizontal vertical rod vertical rod large cross bar small crossbar small cantilever cantilever length 1.5m 1.2m 2.0m 1.5m 0.45M5 ramps board, springboard slope is no larger than 1:3, width of not less than 1.5m. 6 wooden rods: wire with 8#

Send your message to us

Push-pull Steel Prop 1.6M-2.7M Q235 Steel Prop Standard EN1065 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords