PU Sandwich Panel Production Machine with ISO quality system

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

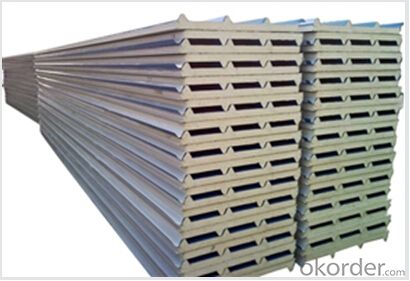

PU Sandwich Panel Production Machine

Brief introduction

Our PU sandwich panel machine is one line that integrates advanced mechanical, chemical, electrical, hydraulic, and pneumatic technologies. Due to its high efficiency and simple operation, this forming machine is widely used in the construction of steel structure enclosures, cold storages, and mobile buildings. In order to satisfy various customer requirements, we design and manufacture PU sandwich panel lines in different specs, models and configurations.

Main Components

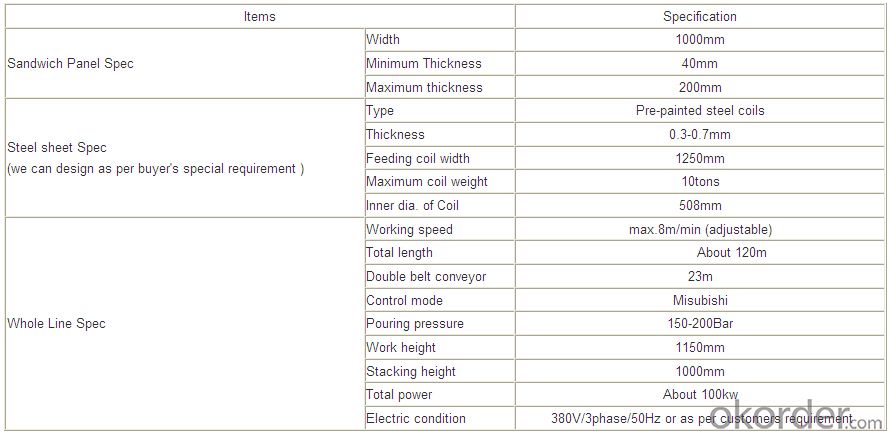

PU sandwich panel machine mainly consists of hydraulic uncoiler, film covering system, roll forming machine, polyurethane foaming system, double belt system, automatic cutting device, electric control system, hydraulic system, and pneumatic system. Stacking system and packing system for option.

Technical specification

Product application of PU Sandwich Panel Production line

Due to its high efficiency and simple operation, this forming machine is widely used in the construction of steel structure enclosures, cold storages, and mobile buildings.

In order to satisfy various customer requirements, we design and manufacture PU sandwich panel producton lines in different specs, models and configurations.

Competitive Advantage:

<!--[if !supportLists]-->1. <!--[endif]-->Designed by 15 years experienced R&D members with lifetime seivices.

<!--[if !supportLists]-->2. <!--[endif]-->We are "All-in-house source" factory to ensure quality and delivery of your machines.

<!--[if !supportLists]-->3. <!--[endif]-->Machine’s lifetime>15 years

<!--[if !supportLists]-->4. <!--[endif]-->Quick delivery: in only 5-8 weeks for urgent order .

<!--[if !supportLists]-->5. <!--[endif]-->Introduced Mitsubishi PLC and touch screen for machine’s control system.

<!--[if !supportLists]-->6. <!--[endif]-->Have our own tool center: 12 sets of CNC machines.

<!--[if !supportLists]-->7. <!--[endif]-->High Pricision perofrmance: Shafts are tooled by grinding machine for two times. Rollers are tooled by CNC machines.

<!--[if !supportLists]-->8. <!--[endif]-->Technician can be sent to your factory to install machines and train your workers.

- Q: Say that China's machine is not good, then they are sold to whom?

- With the progress of society and the development of science and technology, the gap between domestic machine tools and imported machine tools will be getting smaller and smaller.

- Q: What equipment, machine tools, lathes, or other equipment? Probably are a length of not more than 30cm a number of hollow

- Check that each turret should be in a non-working position;

- Q: What can a CNC lathe do?

- 1 to 2 years on the almost a little advanced machine tools on the master's ability and technical requirements are high.

- Q: CNC lathe programming g90 what it means

- HNC CNC lathe G90: absolute value programming.

- Q: Machine operating procedures

- 2, check the machine, workstations, rails and the main sliding surface, such as obstacles, tools, iron, impurities, etc., must be cleaned, wipe clean, oil;

- Q: Which machine is the leading machine

- 000410 Shenyang Machine Tool is the world's first machine tool sales in 2011, China's leading position unmatched, before the NC rate is low (about 30%), the two years of high-end force, which lasted five years of successful research Diaoyang CNC system, NC

- Q: The difference between CNC machine tools and ordinary machine tools

- The other is all mechanical components, there is no automatic control system.

- Q: What tools (machines) are required for lathe processing?

- Turret) for horizontal and vertical movement for precision machining.

- Q: What is the advantage of other CNC machine tools compared to other equipment?

- CNC machine tools compared to other equipment advantages:

- Q: The lathe belongs to the machine? The machine? Other production equipment? The equipment related to the production activity? What kind of classification?

- To the machine equipment category, because the machine is not directly involved in the production, according to the classification of fixed assets, the machine tool process is an expense project, he does not create profits, on the contrary to spend the cost, because you are manufacturing, so this machine process belongs to the auxiliary work class,

Send your message to us

PU Sandwich Panel Production Machine with ISO quality system

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords