High Quality Discontinuous PU Sandwich Panel Product Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set set

- Supply Capability:

- 70 set per year set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

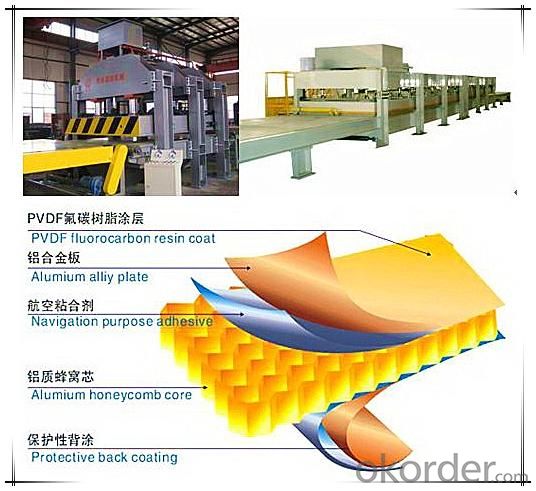

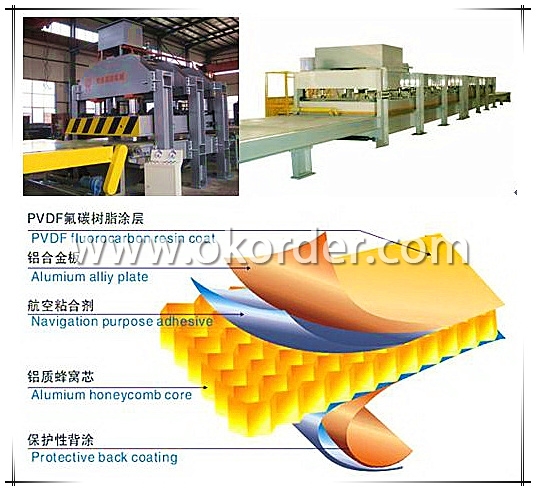

General Information of Multifunctional PU sandwich panel Discontinuous line

We can design the line to make different kinds of panels in appearance, for wall panel and roofing panel with various joint designs.

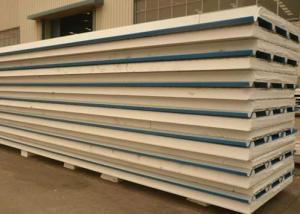

Sandwich panel, as a new building material shows excellent performance on insulation. It is taking the place of brick to be a main material for building now.

Technical Data of High Quality Discontinuous PU Sandwich Panel Product Line:

1. The Manufacture Speed of Sandwich Panel: 8.6m/min( frequency conversion to adjust speed)

2. The Thickness of Sandwich Panel: 30-200mm

3. The Thickness of Steel: 0.4-0.8mm

4. The Length of the Production Line: about 120 meters

5. The Total Power of the Production Line: 350 KW

6. The Length of the Double Belt Conveyer: 24m

PU Sandwich Panel Discontinuous Line

Product introduction of High Quality Discontinuous PU Sandwich Panel Product Line

1 The equipment is accurate and durable.

2 The tape mechanism has a tension control device, enabling the overlay material evenly into the mould, to make sure the piece has a smooth surface.

3 The side block and adhesive tape recirculation device can guarantee the sealing of the piece and its demolding.

4 The double-crawler laminating system is of pressure proof, and can achieve a continuously automatic production and limit the foaming material within the mould, ensuring a stable feature in product size.

5 The following conveying and cutting systems can work simultaneously to produce plates of any length.

Technical Parameters of High Quality Discontinuous PU Sandwich Panel Product Line:

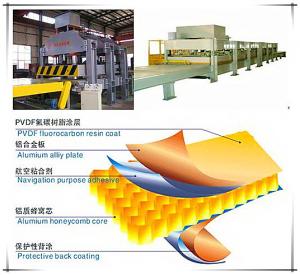

Core material of panel | Polyurethane |

Panel available thickness | 75mm,100mm,120mm,150mm,200mm |

Material of panels surface | Color plate, Stainless Steel, etc. |

Surface of panels thickness | 0.326mm, 0.376mm, 0.426mm, 0.476mm, 0.526mm |

Features of High Quality Discontinuous PU Sandwich Panel Product Line:

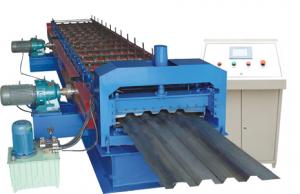

1. Beautiful appearance, low noise, high efficiency

2. Multiple functions: could produce 4 kinds of panel, wall pane, roof panel, cold room panel, and garage door panel.

3. The line employs advanced PLC and sets the panel length and cuts the panel automatically.

4. The main body is welded with type "H" section steel as its material, strong strength.

5. The roll forming machine is adjustable, the suitable width range is 600-1250mm

6. The roller martial is medium carbon alloy steel, with high quality.

7. The length of double belt laminating machine could be made according to customers’ needs.

- Q: Classification of sandwich panels

- Three polyester sandwich panel, or PIR sandwich panel;Phenolic sandwich panel, or PF sandwich panel;Rock wool sandwich board, or RW sandwich panel.Foam metal sandwich panel

- Q: Can the oil on the sandwich board be painted?

- When spraying, the thinner is easy to penetrate into the plate, the sandwich board is glued laminated board, it is easy to dissolve the glue, the separation of the layer.

- Q: What do you want to consider if you want to buy a sandwich panel production line?

- You don't know where is the statistics, color steel production line really the most private owner, but you do not have with Hebei Botou and Xinji the two production base, Shanghai original equipment really good, but along with the market competition and their quality is declining, which is now not to say, mainly to see their weight, the other is secondary, Beijing have never heard of the production of steel machinery.

- Q: What is the color steel sandwich board?

- The intermediate sandwich panel is two color steel with polyurethane foam with a layer of insulating material.

- Q: Polyurethane sandwich panel production line?

- Polyurethane sandwich board is polyurethane as the double metal surface and the insulation layer of the single metal surface, non metal surface composite board, commonly used in industrial workshop, warehouse logistics, integrated building wall, roof enclosure system.

- Q: Can the sandwich board adhere to the plaster line?

- Gypsum lines and gypsum board belong to the decoration "surface layer", the same strength of the structure, and therefore can not be based on each other. That is to say, it must be attached to the joinery board below.

- Q: What's the difference between sandwich board and composite board?

- Building insulation board industry, insulation composite board refers to sandwich board, composite board is popular name.

- Q: What are the causes of uneven surface of polyurethane sandwich panel produced by continuous production line?

- Uneven heating of sheet material leads to uneven solidification of Pu material.

- Q: What's the difference between a polyurethane sandwich panel and a foam sandwich panel?

- The common point is that the sandwich panels are all made of hard protective coatings, and the difference is that the materials in the center are different.

- Q: How to install the pre embedded pipe in the clean room sandwich panel?

- The general principle is that ceilings and walls are not dusty, not dust, bacteria, easy to clean, corrosion resistance, lighting should be used without dust, easy to clean the purification lamp, the color is elegant and fresh. To achieve the clean room decoration requirements, the construction process is critical.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2003 |

| Annual Output Value | |

| Main Markets | North America Eastern Asia Africa Southeast Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | 10 people |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 25000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

High Quality Discontinuous PU Sandwich Panel Product Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set set

- Supply Capability:

- 70 set per year set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches