Hot Seller Continuous PU Sandwich Panel Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

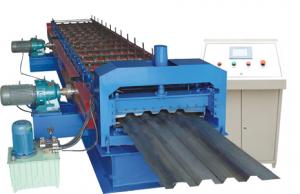

General Information of Hot Seller Continuous PU Sandwich Panel Production Line

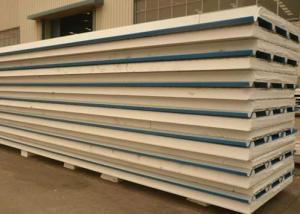

We can design the line to make different kinds of panels in appearance, for wall panel and roofing panel with various joint design.

Sandwich panel, as a new building material show excellent performance on insulation. It is taking the place of brick to be a main material for building now.

Technical Data of PU Sandwich Panel Production Line

1. The Manufacture Speed Of Sandwich Panel:8.6m/min( frequency conversion to adjust speed)

2. The Thickness Of Sandwich Panel:30-200mm

3. The Thickness Of Steel : 0.4-0.8mm

4. The Length Of The Production Line : about 120 meters

5. The Total Power Of The Production Line : 350 KW

6. The Length Of The Double Belt Conveyer : 24m

- Q: How to thread the EPS (color steel) sandwich panel?

- Of course, PVC flame retardant tubes, ha ha, I suggest that our company is to do foam sandwich board, the general customers are doing so.

- Q: Color tile and color steel sandwich plate what is the difference, the use of what is the difference?

- Also known as color: color steel tile is used in color coated steel sheet, roll cold forming pressure plate and various wave types, it is suitable for industrial and civil buildings, warehouses, special buildings, large-span steel structure house roof, walls and wall decoration etc.

- Q: Can the oil on the sandwich board be painted?

- Sandwich panels of better quality can be painted, but a decorative panel is recommended.

- Q: What do you want to consider if you want to buy a sandwich panel production line?

- Now there is the middle lane is a honeycomb galvanized plate board online, I know this is the direction of future development is the absolute fire, there is air, that summer is not too hot, winter is not too cold.

- Q: Polyurethane sandwich panel production line?

- Polyurethane sandwich board is polyurethane as the double metal surface and the insulation layer of the single metal surface, non metal surface composite board, commonly used in industrial workshop, warehouse logistics, integrated building wall, roof enclosure system.

- Q: Can the sandwich board adhere to the plaster line?

- Gypsum lines and gypsum board belong to the decoration "surface layer", the same strength of the structure, and therefore can not be based on each other. That is to say, it must be attached to the joinery board below.

- Q: What's the difference between sandwich board and composite board?

- Building insulation board industry, insulation composite board refers to sandwich board, composite board is popular name.

- Q: Rock wool, color steel sandwich plate production line where good?

- Company's R & D and production of rock wool polyurethane sandwich board equipment, rock wool, /EPS color steel sandwich board equipment, can produce all kinds of different types of fire insulation board.

- Q: What does color steel sandwich board mean?

- Can be called composite board and rock wool board: it is double deck color steel, sandwiched between foam or rock wool, the upper layer is a color panel.

- Q: How to install the pre embedded pipe in the clean room sandwich panel?

- The general principle is that ceilings and walls are not dusty, not dust, bacteria, easy to clean, corrosion resistance, lighting should be used without dust, easy to clean the purification lamp, the color is elegant and fresh. To achieve the clean room decoration requirements, the construction process is critical.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1997 |

| Annual Output Value | US$ 2.5 Million - US$ 5 Million |

| Main Markets | South America Eastern Europe Africa Oceania Mid East Western Europe Northern Europe Southern Europe South Asia |

| Company Certifications | ISO 9001:2000 ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | Chinese, English |

| b) Factory Information | |

| Factory Size: | Above 2000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Hot Seller Continuous PU Sandwich Panel Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches