Low Pressure Continuous Sandwich Panel Production Line

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set set

- Supply Capability:

- 100 set per month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

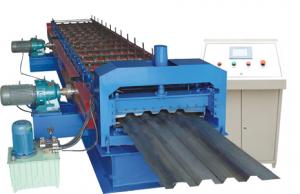

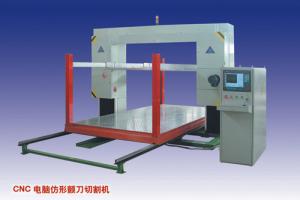

General Information of Low Pressure Continuous PU Sandwich Panel Production Line

We can design the line to make different kinds of panels in appearance, for wall panel and roofing panel with various joint designs.

Sandwich panel, as a new building material shows excellent performance on insulation. It is taking the place of brick to be a main material for building now.

Specifications of Low Pressure Continuous PU Sandwich Panel Production Line

Reuqire specifications of raw materials:

Thickness of panel: 0.37-1.2mm

Track width (max): 1250mm

Weight of uncoil (max): 5 tons

Inner dia: 500-600mm

Dimension of the sandwich panel available to produce

Length: 2-20m

Width: 900-1100mm

Panel thickness (min): 30mm

Panel thickness (max): 200mm

Production/Operation rate: 3-10m/min

Length of the whole production line: about 120m

Useful length of the double track: 25m

Working height: 1200mm

The pressure of pour foaming: 150-200 bar

Complete line consist of:Uncoiler (auto), Forming machine, Steel/Panel heating machine, Heating frame (move auto), Foaming machine, Main engine with double track, Heating machine with double track, Band saw cutter, Automatic stacker and Auto electric controller

Applications of Low Pressure Continuous PU Sandwich Panel Production Line

This metal forming machine is indispensable equipment for producing the wall panel and roof panel for industrial workshops, warehouses etc.

Technical Data of Low Pressure Continuous PU Sandwich Panel Production Line

1. The Manufacture Speed Of Sandwich Panel:4m/min

2. The Thickness Of Sandwich panel:30-200mm

3. The Thickness Of Steel : 0.4-0.8mm

4. The Length Of the Production Line : about 80meters

5. The Total Power Of The Production Line : 200KW

6. The Length Of The Double Belt Conveyer : 8m

Packaging & Delivery of Low Pressure Continuous PU Sandwich Panel Production Line

1. Main machine is covered by plastic film.

2. PLC computer control box, spare parts and other small parts are packed by wooden carton box.

3. Delivery: 80 days.

- Q: Characteristics of sandwich panels

- Light weight, less than 24kg per square meter weight, can fully reduce the structural cost.

- Q: How to thread the EPS (color steel) sandwich panel?

- Of course, PVC flame retardant tubes, ha ha, I suggest that our company is to do foam sandwich board, the general customers are doing so.

- Q: Color tile and color steel sandwich plate what is the difference, the use of what is the difference?

- Also known as color: color steel tile is used in color coated steel sheet, roll cold forming pressure plate and various wave types, it is suitable for industrial and civil buildings, warehouses, special buildings, large-span steel structure house roof, walls and wall decoration etc.

- Q: Can the oil on the sandwich board be painted?

- Sandwich panels of better quality can be painted, but a decorative panel is recommended.

- Q: What do you want to consider if you want to buy a sandwich panel production line?

- You don't know where is the statistics, color steel production line really the most private owner, but you do not have with Hebei Botou and Xinji the two production base, Shanghai original equipment really good, but along with the market competition and their quality is declining, which is now not to say, mainly to see their weight, the other is secondary, Beijing have never heard of the production of steel machinery.

- Q: Rock wool, color steel sandwich plate production line where good?

- Jizhong Machinery Manufacturing Co., Ltd. has won the title of state-level high-tech enterprises, and has been recognized by the Ministry of Commerce as a designated equipment export manufacturer.

- Q: What are the causes of uneven surface of polyurethane sandwich panel produced by continuous production line?

- The problems in forming of pressing sheet. It may be caused by the bending residual stress of the plate during forming;

- Q: What's the difference between a polyurethane sandwich panel and a foam sandwich panel?

- The common point is that the sandwich panels are all made of hard protective coatings, and the difference is that the materials in the center are different.

- Q: What does color steel sandwich board mean?

- The color steel sandwich panel product is composed of two layers of formed metal panels (or other material panels) and a macromolecule heat insulation inner core which is directly foamed and matured in the middle of the panel.

- Q: How to install the pre embedded pipe in the clean room sandwich panel?

- Clean room decoration requirements are very special, do not allow the use of decorative lines and other special protrusions, Yin, Yang Kok should be made of arc, wall and ceiling should be smooth, smooth, no seams or seams tight.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2008 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Eastern Europe North America Southeast Asia Africa South America North America |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 8-10people |

| Language Spoken: | Chinese, English |

| b) Factory Information | |

| Factory Size: | 10,000square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Low Pressure Continuous Sandwich Panel Production Line

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set set

- Supply Capability:

- 100 set per month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords