Roll Forming Machinery -Sandwich panelPRL-6-SA1

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information:

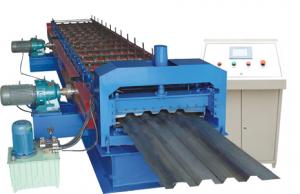

We can designthe line to make different kinds of panels in appearance, for wall panel androofing panel with various joint designs.

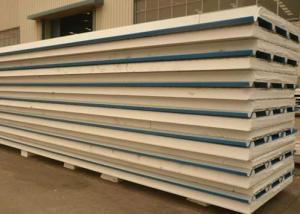

Sandwichpanel, as a new building material,shows excellent performance oninsulation.

It is takingthe place of brick to be a main material for building now.

High speedslitting and cut to length can cut steel with thickness from 1mmto 16mm, if noneed slitting thickness up to 30mm.

Processing flow is as following:

Carry coil→loadcoil→de-coiling(pressingguide +opener)→entry、roughlevel→cutting→transition→guide→slitting (waste winding) →loopingstorage→pre-separating, damping→recoiling→packing→discharging→guide→leveling→fix size (end platefeeding)→cutting→discharging

Technical Data:

1. TheManufacture Speed Of Sandwich Panel:8.6m/min( frequency conversion to adjustspeed)

2. TheThickness Of Sandwich Panel:30-200mm

3. TheThickness Of Steel : 0.4-0.8mm

4. TheLength Of The Production Line : about 120 meters

5. TheTotal Power Of The Production Line : 350 KW

6. TheLength Of The Double Belt Conveyer : 24m

- Q: Classification of sandwich panels

- Rigid polyurethane sandwich panel, i.e. PU sandwich panel;Three polyester sandwich panel, or PIR sandwich panel;

- Q: How can the wire laying in the foam sandwich panel workshop meet the fire protection requirements?

- New composite plate is a new type of building materials developed rapidly in five to ten years, because these new building materials can meet the technical indicators of building structure, insulation and other related aspects, and has the advantages of low cost, light weight, convenient construction investment Sheng, reusable characteristics, has been strongly recommended by the administrative Department of construction.

- Q: How to thread the EPS (color steel) sandwich panel?

- It depends on understanding! It is always more difficult than the way!

- Q: Color tile and color steel sandwich plate what is the difference, the use of what is the difference?

- Color steel sandwich panel is a common product in building materials, not only good flame retardant, sound insulation, but also environmental protection and high efficiency. The color steel sandwich panel is composed of two layers: metal panel and middle layer macromolecule insulation core. The utility model has the advantages of simple installation, light quality, environmental protection and high efficiency. Moreover, the structure of the closed bubble used in the filling system can prevent the condensation of water vapor.

- Q: Can the oil on the sandwich board be painted?

- Sandwich panels of better quality can be painted, but a decorative panel is recommended.

- Q: What do you want to consider if you want to buy a sandwich panel production line?

- Now there is the middle lane is a honeycomb galvanized plate board online, I know this is the direction of future development is the absolute fire, there is air, that summer is not too hot, winter is not too cold.

- Q: How is the sandwich plate synthesized?

- The sandwich panel is made up of two layers of metal panels (or other material panels) and a macromolecule heat insulation inner core which is directly foamed and matured in the middle of the panel.

- Q: What is the color steel sandwich board?

- Color steel sandwich plate refers to the color steel clip some insulation board, mainly with some movable board room use.

- Q: What are the causes of uneven surface of polyurethane sandwich panel produced by continuous production line?

- Uneven heating of sheet material leads to uneven solidification of Pu material.

- Q: What's the difference between a polyurethane sandwich panel and a foam sandwich panel?

- The production of polyurethane sandwich panel requires advanced sandwich panel continuous production line. The process is made of internal and external zinc plating (aluminized zinc), colored steel plate cold bending forming, and middle coating polyurethane rigid foam.

Send your message to us

Roll Forming Machinery -Sandwich panelPRL-6-SA1

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches