EPS and Rockwool Sandwich Panel Line

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set set

- Supply Capability:

- 100 set per month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Sandwich composite panel line:

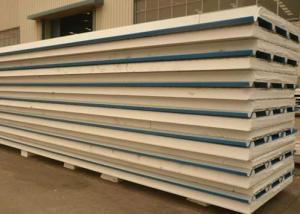

We can design the line to make different kinds of panel in appearance, for wall panels and roofing panels with various joint design. Sandwich panel, as a new building material show excellent performance on insulation. It is taking the place of brick to be a main material for building now.

Specifications of EPS and Rockwool Sandwich Panel Line

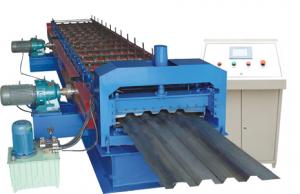

The whole line consists of uncoil device, forming system, cutting device, compounding system(beading, pasting, heating ,compounding, flanging, slotting, edging, pneumatic and auto-cutting).

Features of Sandwich composite panel line:

1. Adopting advanced technology, it combines air, electricity and machine system.

2. Adopting computer control stepless speed regulation, it is smooth in running and easy in operation.

3. According to customers' requirement, the length is controlled by the computer, with an accurate orientation.

4. Time is showed on the touch screen, counting and revising automatically.

5. The outline of the panel can be designed and revised on customers' requests.

Applications of Sandwich composite panel line:

This metal forming machine is indispensable equipment for producing the wall panel and roof panel for industrial workshops, warehouses etc.

Technical Data of Sandwich composite panel line:

1. The Manufacture Speed Of Sandwich Panel:0-4.05m/min

2. The Thickness Of Sandwich Panel:50-250mm

3. The Exterior Dimension Of The Product Line : length×width×height, 56000×4500×2800

4. The Total Capacity Of The Product Line : 50kw

5. The Output Of the Sandwich Panel:1500-2000m2/8 hours

Packaging & Delivery of Sandwich composite panel line:

1. Main machine is covered by plastic film.

2. PLC computer control box, spare parts and other small parts are packed by wooden carton box.

3. Delivery:80 days

- Q: How to thread the EPS (color steel) sandwich panel?

- Of course, PVC flame retardant tubes, ha ha, I suggest that our company is to do foam sandwich board, the general customers are doing so.

- Q: Color tile and color steel sandwich plate what is the difference, the use of what is the difference?

- Color steel sandwich panel is a common product in building materials, not only good flame retardant, sound insulation, but also environmental protection and high efficiency. The color steel sandwich panel is composed of two layers: metal panel and middle layer macromolecule insulation core. The utility model has the advantages of simple installation, light quality, environmental protection and high efficiency. Moreover, the structure of the closed bubble used in the filling system can prevent the condensation of water vapor.

- Q: What do you want to consider if you want to buy a sandwich panel production line?

- Now the mainstream is rock wool board, but now the profit is not high, other equipment is still in the monopoly of foreign countries, I don't know what kind of you produce, but I hope you can produce new varieties.

- Q: How is the sandwich plate synthesized?

- The sandwich panel is made up of two layers of metal panels (or other material panels) and a macromolecule heat insulation inner core which is directly foamed and matured in the middle of the panel.

- Q: What is the color steel sandwich board?

- Color steel sandwich plate refers to the color steel clip some insulation board, mainly with some movable board room use.

- Q: Polyurethane sandwich panel production line?

- Products are mainly used for exterior wall insulation and central air conditioning, air supply pipe. The working principle of polyurethane perfusion machine by measuring liquid pump in a certain proportion into the mixing head after mixing evenly pouring in sandwich bottom material, and the upper surface of a layer in the layer of transport to the press, press under the chain plates foam curing; sandwich plate after curing in the production line both sides trimmed, automatic track cutting machine cut to length of the products.

- Q: Can the sandwich board adhere to the plaster line?

- Carpentry board is big core board, it is solid wood to spell, gesso board is gesso to make, outside a layer of kraft paper, two material is different. Wood board is commonly used materials currently Jiezhuang, generally used as lining making furniture, door, use is very extensive. Gypsum board is generally used for ceiling, television, wall and so on, but it needs carpentry rendering.

- Q: What's the difference between sandwich board and composite board?

- Building insulation board industry, insulation composite board refers to sandwich board, composite board is popular name.

- Q: What does color steel sandwich board mean?

- Can be called composite board and rock wool board: it is double deck color steel, sandwiched between foam or rock wool, the upper layer is a color panel.

- Q: How to install the pre embedded pipe in the clean room sandwich panel?

- Clean room decoration requirements are very special, do not allow the use of decorative lines and other special protrusions, Yin, Yang Kok should be made of arc, wall and ceiling should be smooth, smooth, no seams or seams tight.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2007 |

| Annual Output Value | Below US$1 Million |

| Main Markets | 23.41% Eastern Europe 20.29% Southeast Asia 16.91% Mid East 11.68% Africa 11.00% South America 8.74% North America 4.30% Eastern Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Xingang Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

EPS and Rockwool Sandwich Panel Line

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set set

- Supply Capability:

- 100 set per month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords