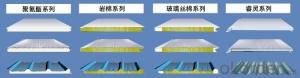

Phenolic Foam/Polyurethane Sandwich Panel Production Line

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Phenolic Foam/Polyurethane Sandwich Panel Production Line

Introduction of the Equipment

Phenolic Foam/Polyurethane Sandwich Panel Production Line is a professional machine for manufacturing Sandwich Panels of which the core material is phenolic foam or polyurethane and of which both layers is embossed aluminium foil or colored steel. The thickness of sandwich panel is 20-200mm, the width 1200mm and the length according to customers’ request. The sandwich panels are used as the air ducts in Central air conditioning. The machine can used to make other insulation panel as long as the surface material is changed. The working principle of the machine is as below: mix the raw materials with a certain ration in a container and then pour the mixture on the interlayer of the sandwich panel. Then the raw materials has the chemistry reaction of foaming and solidifying. In the end the automatic tracking cutting machine cuts the panels into a certain length.

The Components and Its Function

The components include: the aluminium foil embossing machine, the raw material distributor, the aluminium foil/colored steel pre-heating installation, the material-baffling mechanism, the automatic tracking cutting machine, the roller supporters and brackets. All the components can be individually adjusted.

The Aluminium Foil Embossing Machine

The embossing machine include three parts: the charging unit, the embossing unit and the windin unit. It is used to emboss figures and logos under certain surface tension on the aluminium foil (Width: 1200mm, thickness: 0.08-0.12mm).

The Raw Material Distributor / The Raw Material Charging Unit

This device is installed at the forefront of the production line and the laminator. It can adjust the location and control the surface tension of the aluminum foil and the colored steel before entering the laminator.

The Aluminium Foil/Colored Steel Pre-heating Installation

Before entering the injection machine, the temperature of the aluminum foil or the colored steel must meet the requirement of the foaming technology of the PF or PU. And thermodynamic cycle device on the production line can control the temperature of the aluminum foil or colored steel.

The Material-baffling Mechanism

The material-baffling mechanism is used to stick Kraft paper to both sides of the lower aluminum foil before entering the injection machine. So there is a enclosed area between the upper aluminum foil and the lower one. With the Kratf paper, there will be no leakage of the raw materials when the machine is working.

The Reaction Injection Machine

The reaction injection machine is used to calculate the computation and mix of raw materials pro rata. In order to make the temperature of the raw materials meet the requirement of the foaming technology, the machine is equipped with heating, refrigerating and temperature control devices. In addition, People can control the pressure, the computation of the raw matrials by this machine. And the process of injection, cleaning and sweeping are automatically controlled. The equipment is equipped with three tanks, two for resin materials, one for curing agent material.

The Back-and-forth Injection Machine

This machine is used to apply the mixture on the lower aluminum foil or the colored steel. The injection head is drived by fluid drive, and its speed, moving frequency, transverse moving distance is adjustable.

The laminating conveyor is used for the laminating and the shaping of the sandwich panel. This machine adopts the driving structure of drag chain. The chain is made of fine aluminum alloy and is 18m long. The moving speed is 3-8m/min and is controlled by frequency conversion. If the customers want to improve the moving speed, they can customize a longer conveyor. The thickness is controlled by the space between the upper link plate and the lower one. The startup of the link plate is control by fluid drive. The 12 tilt cylinder is adjustable so that the link plates can stops at any position.

The Heated Air Circulation Device

To meet the expected requirement of foaming technology, the production line is equipped with a heated air circulation device. Its used to heat the link plates to 70℃. Its made up of one hot blast stove, one diesel-oil-drived stove and two temperature sensors. The temperatue sensors are placed at the inlet port and inside the conveyor so the operator can monitor the temperature fluctuation.

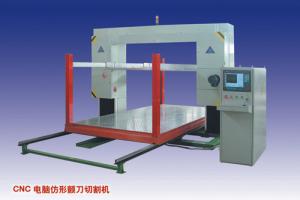

The Automatic Tracking Cutting Machine

The panels are cutted into different lengths by this machine.

MAIN TECHNICAL PARAMETER OF THE PRODUCTION LINE

Specification of Sandwich Panel | Width*Thickness (mm) | 1200×(20~200) |

The Production Speed | m/min | arbitrary |

The Embossing Speed | m/min | ≤20 |

The Mixing Speed | round/min | 4500 |

The Moving of Injection Head | times/min | ≤80 |

The Max temperature of the heated air circulation device | ℃ | 70 |

The Laminating Length of the Conveyor | M | 18.82 |

The Max start-up Speed of the Conveyor | mm | 300 |

Total Power | KVA | 85~125 |

The Specification of the Production Line | mm | 40950×5620×3700 |

The Specification of the Embossing Machine | mm | |

Weight | T | ≈34 |

Note: The above information is for our standard production line and we can make it according to customers request. We will send our techician to our customers to install and debug the machines.

- Q: Who helped me find a design design for a leisure chair? Requires more than 1000 words to a few programs

- Who helped me find a design design for a leisure chair? Requires more than 1000 words to a few programs

- Q: Upstairs health asked what kind of material leakage with smashed brick

- The coating has the characteristics of low temperature resistance and high elongation

- Q: Multi-function Dr. brand impact drill 1500w high power how much money one

- Impact drill (electricimpactdrill), mainly to the rotary cutting, both rely on the operator to produce the impact of the impact of the impact of institutions, for brick, block and light wall materials such as drilling on the power tools Impact drill can be used for natural stones or concrete They are generic, because they can use the "single drill" mode, you can also use the "impact drill" mode, so the professionals and their own hands, it is worth choosing the basic power tools The hammer works by rotating and hammering The single hammering force is very high and has a beat frequency of 000 to 000 per minute, producing a significant force Compared with the impact drill, the hammer requires minimal pressure to drill hard materials, such as stones and concrete; especially relatively hard concrete The drill is only rotatable and is particularly suitable for drilling holes in materials that require very small forces, such as cork, metal, brick, tiles and so on The impact drill relies on rotation and shock to work The single impact is very slight, but the impact frequency of more than 000 times per minute can produce a continuous force

- Q: What are the sound insulation of the bar? Is there a noiseproof sound from the bar?

- Bar inorganic fiber spraying is a special fiber spraying machine, the special technology of inorganic fiber cotton and special water-based adhesive, instantly mixed after the eruption in the appearance of the spray, constitute a certain strength of the three-dimensional insulation, Sound-absorbing fiber layer products

- Q: What kind of waterproof repair agent as a moisture-proof decoration design materials?

- If there is a house wall or ground (especially the bathroom) a small gap, may wish to buy this waterproof repair agent yourself try Moisturizing paste also has a similar effect In fact, I was a few days ago in the Bay Tin home network to see a lot of knowledge on this, I suggest you go to see

- Q: What are the main types of materials for outdoor flooring when they are made updoors?

- Ground pavement one is to the overall style and place environment and activities fit, not too unexpected, the second is to use high-quality materials, can withstand the wear and tear of adults, and to have a non-slip function, environmentally friendly Traditional decoration materials only tiles and wooden flooring and ordinary carpet can choose, but the tiles of non-slip performance is not good, wood flooring and not wear, pavement is not convenient All with alternative ground pavement of new materials after the ground began to gradually become humane DDK produced by the ground pavement materials made of international quality of new materials made of wear-resistant pressure, anti-skid function significantly, environmental science, after special treatment, can have to prevent burning, anti-pollution, anti-pest and so on In addition to the coil series, the combination of the introduction of the assembly series is very convenient, can be directly applied to the laying of most of the ground, easy to lay Easy to cut With shock absorption, noise reduction, compression, wear, anti-skid, anti-fatigue characteristics Its excellent performance has been a good reputation in the industry, the market influence is also growing

- Q: Is New Fox Blue Paint Is Metal Paint? What brand of car what brand car wax better?

- Only Patan wax is the best If you are waxing yourself, I never give people a hat

- Q: How is the multi-functional waterproof coating? How much is a bucket?

- The quality of the effect is not very good You can Google Oriental Rainbow's official website, there are rainbow days cat flagship store and other links will have the price and product display, I suggest you choose the East Rainbow waterproof products and standardized construction team, the East Rainbow is the best quality Waterproof listed companies JSA-101 polymer cement waterproof coating "Rainbow" brand JSA-101 polymer cement waterproof coating is a two-component water-based waterproof coating, liquid material is a high-quality polymer emulsion and a variety of functional additives, Material is composed of special cement and a variety of additives, the use of a certain percentage of mixed use

- Q: I just entered the community soon, want to join the textile industry, do not know which place is now optimistic, from a long-term perspective.

- The main direction: filter textile processing technology and development and application of acupuncture, spunlace, spunbond nonwovens and machine Weaving efficient filtering with textile materials and products of complete sets of processing technology and industrial applications

- Q: May Tibet Zijia You, three or five cars, there are Land Rover Porsche and so I personally and the car to prepare what, along the way to pay attention to what the route for the choice of what

- Second, choose the driving route, to follow the first highway, followed by the principle of national highway

Send your message to us

Phenolic Foam/Polyurethane Sandwich Panel Production Line

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords