Professional 310s 309s 904l Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

316 stainless steel, 18Cr-12Ni-2.5Mo because adding Mo, so the corrosion resistance, weather resistance and high temperature strength in particular, in the harshness of the conditions of use

316L stainless steel containing molybdenum species, the steel containing molybdenum, the overall performance is better than steel 310 and 304 stainless steel, high temperature conditions, 316L stainless steel also has good resistance to chloride corrosion performance, it is usually used in the marine environment.

| Artical | sus 316l cold rolled stainless steel dinner plate | ||||||

| Specification | 1000mm*2000mm,1219mm*2438mm or as your requirement | ||||||

| Surface | 2B | ||||||

| Type | plate | ||||||

| Thickness | 0.3mm-1mm,1.2mm,1.5mm,2mm,2.5mm,3mm-6mm or as customized | ||||||

| Mill | TISCO/ BAOSTEEL/ JISCO/ ZPSS | ||||||

| Packing | standard export packing | ||||||

| Payment terms | 1.30%T/T in advance, the balance against the B/L copy | ||||||

| 2.30%T/T in advance, the balance against the L/C at sight | |||||||

| 3.100%L/C at sight | |||||||

| Dilivery time | 1.10days after receving the deposit of T/T | ||||||

| 2.10days after receving the L/C original | |||||||

chemical properties

| Typical chemical composition | ||

| % | 316 | 316L |

| C | 0.8 | 0.03 |

| Mn | 2 | 2 |

| Si | 0.75 | 0.75 |

| P | 0.045 | 0.045 |

| S | 0.03 | 0.03 |

| Cr | 16.0-18.0 | 16.0-18.0 |

| Ni | 10.0-14.0 | 10.0-14.0 |

| Mo | 2.00-3.00 | 2.00-3.00 |

| N | 0.1 | 0.1 |

| Fe | - | - |

Pysical properties

Tensile strength σb (MPa) ≥ 520

Conditions yield strength σ0.2 (MPa) ≥ 205

Elongation δ5 (%) ≥ 40

Section shrinkage ψ (%) ≥ 60

Hardness: ≤ 187HB; ≤ 90HRB; ≤ 200HV

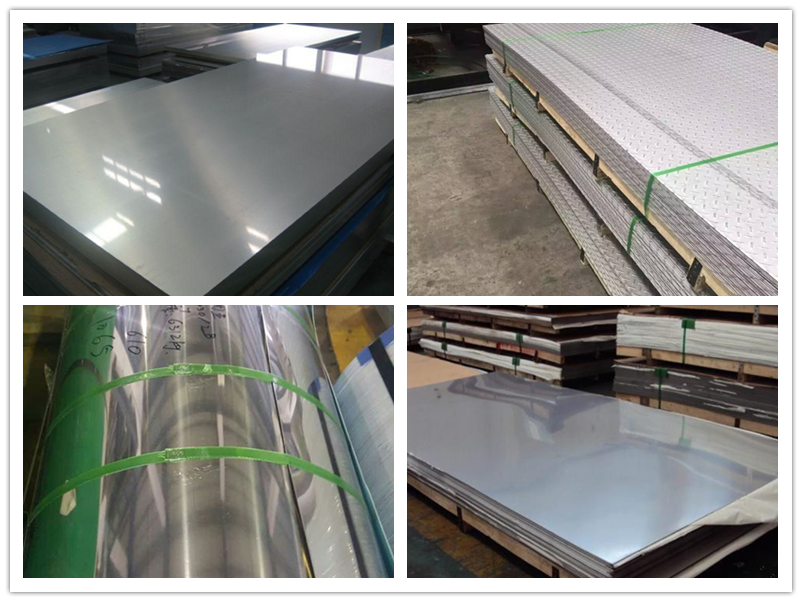

Detailed Images

Packaging & Shipping

Application

- Q: Can stainless steel sheets be used for flooring?

- Certainly, flooring can indeed be made using stainless steel sheets. Stainless steel, being a sturdy and adaptable substance, possesses resistance against corrosion, stains, and scratches, thereby rendering it fitting for areas with heavy foot traffic. It is frequently employed in commercial and industrial environments like hospitals, kitchens, and food processing plants, where cleanliness and hygiene hold paramount importance. Stainless steel flooring imparts a polished and contemporary appearance, is effortless to clean and maintain, and can endure substantial loads and extreme temperatures. Furthermore, stainless steel sheets can be personalized to suit any area and can be installed with different finishes to augment slip resistance.

- Q: How do you prevent galvanic corrosion on stainless steel sheets?

- One way to prevent galvanic corrosion on stainless steel sheets is to ensure that they are not in direct contact with dissimilar metals. This can be achieved by using insulating materials, such as rubber gaskets or plastic washers, between the stainless steel sheets and any other metal surfaces they come into contact with. Additionally, regular cleaning and maintenance of the stainless steel sheets can help remove any potential corrosive agents and minimize the risk of galvanic corrosion.

- Q: What are the different methods of cutting stainless steel sheets?

- There are several methods available for cutting stainless steel sheets, depending on the specific requirements and desired precision. 1. Shearing: This is one of the most common methods used for cutting stainless steel sheets. It involves using a shearing machine with sharp blades to cut through the material. Shearing is ideal for straight cuts and is relatively fast and cost-effective. 2. Laser cutting: Laser cutting is a highly precise method that uses a high-powered laser beam to cut through stainless steel sheets. It provides a clean and smooth cut, and can be used to create intricate designs or complex shapes. Laser cutting is widely used in industries that require high precision and quality finishes. 3. Plasma cutting: Plasma cutting uses a high-temperature plasma arc to melt through stainless steel sheets. This method is suitable for cutting thick stainless steel sheets or materials with high conductivity. Plasma cutting offers fast cutting speeds and can handle various shapes and thicknesses. 4. Waterjet cutting: Waterjet cutting involves using a high-pressure jet of water mixed with abrasive particles to cut through stainless steel sheets. This method is highly versatile and can create complex shapes with high precision. Waterjet cutting is also a cold cutting process, which means it does not produce heat-affected zones or alter the material's structure. 5. Abrasive cutting: This method uses an abrasive wheel or disc to grind and cut through stainless steel sheets. It is commonly used for rough cuts or in situations where other methods are not feasible. Abrasive cutting can be done manually or with the help of power tools, such as angle grinders. Each of these cutting methods has its own advantages and limitations, and the choice of method depends on factors such as the thickness of the stainless steel sheet, desired precision, budget, and production requirements.

- Q: Can stainless steel sheets be used for food preparation surfaces?

- Food preparation surfaces can indeed utilize stainless steel sheets. The reason behind stainless steel's popularity for such surfaces is its remarkable characteristics. Being non-porous, it avoids the absorption of any liquids or bacteria that can contaminate the food. Moreover, stainless steel exhibits resistance to corrosion, staining, and rusting, thereby ensuring its durability and longevity for food preparation surfaces. Furthermore, stainless steel can be easily cleaned due to its ability to withstand high temperatures and resistance to most cleaning agents. This fact makes it a hygienic option for food preparation surfaces, as it allows for thorough sanitization to prevent bacterial growth. In conclusion, stainless steel sheets provide a secure and practical alternative for food preparation surfaces.

- Q: Seeking stainless steel plate 304 material and 304j material what is the difference?

- 304 material and 304J1 contain nickel different, 304J1 contain 6 nickel, 304 contain 8 nickel

- Q: What are the benefits of using mirror-finish stainless steel sheets?

- Mirror-finish stainless steel sheets offer several benefits. Firstly, they provide a sleek and modern aesthetic appeal, making them a popular choice for interior and architectural design. Additionally, the reflective surface of these sheets creates the illusion of a larger space, making them ideal for small areas. Mirror-finish stainless steel also has superior corrosion resistance, making it a durable option for outdoor applications. The smooth surface is easy to clean and maintain, reducing the need for frequent upkeep. Finally, mirror-finish stainless steel sheets are often used in food processing and medical industries due to their hygienic properties and ability to resist bacterial growth.

- Q: What are the common sizes and thicknesses of stainless steel sheets?

- The common sizes and thicknesses of stainless steel sheets vary depending on their intended use. However, some common sizes range from 4 feet by 8 feet to 5 feet by 10 feet, while thicknesses can range from 0.4 mm to 6 mm.

- Q: What are the different types of perforated patterns available for stainless steel sheets?

- There are several different types of perforated patterns available for stainless steel sheets, including round, square, slotted, and decorative patterns. Each pattern offers a unique aesthetic appeal and functional characteristics, making it suitable for various applications.

- Q: How is stainless steel different from other types of steel?

- Stainless steel is different from other types of steel primarily because of its high resistance to corrosion, making it much more durable and long-lasting. Additionally, stainless steel contains a minimum of 10.5% chromium, which forms a protective layer on the surface, preventing staining and rusting. This unique composition also gives stainless steel its distinctive shiny appearance, making it aesthetically appealing.

- Q: What is the tensile modulus of stainless steel sheets?

- The grade and specific composition of stainless steel sheets determine the variation in their tensile modulus. Nevertheless, stainless steel is widely recognized for its remarkable mechanical properties and high tensile strength. Typically, the tensile modulus of stainless steel sheets falls within the range of 180 to 200 GPa (Gigapascals), surpassing the majority of commonly utilized engineering and construction materials. This exceptional tensile modulus renders stainless steel sheets perfect for applications demanding robustness, longevity, and resistance against corrosion.

Send your message to us

Professional 310s 309s 904l Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords