Printing Tinplate Coils With Prime Quality for 0.29mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Printing Tinplate Coils With Prime Quality for 0.29mm

1.Structure of Description

Printing Tinplate Coils With Prime Quality for 0.29mm is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

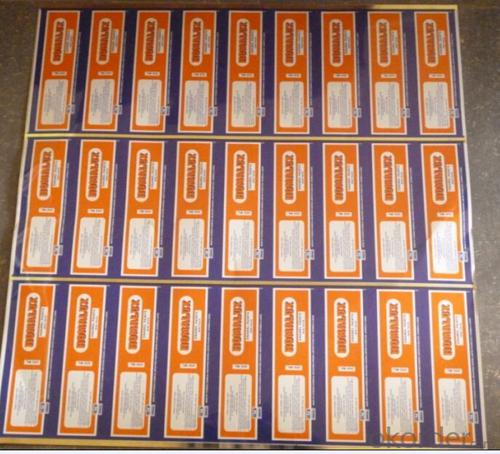

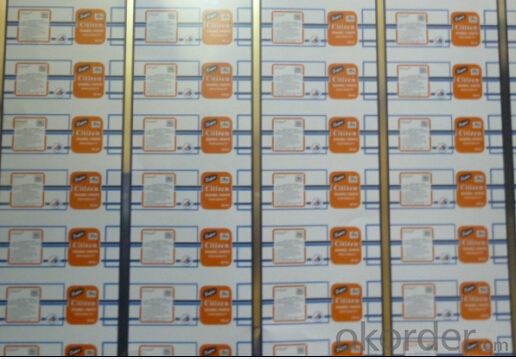

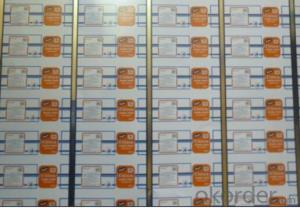

3. Images

4. Specification

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.29

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

5.FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

C. What quantity is the minimum order of tinplate?

Usually, the minimum quantity is 25MT. For special case, consult with us.

D. Can it make to be BA or CA for annealing?

Yes, both can do with.

- Q: How does tinplate packaging contribute to product protection against leakage?

- Tinplate packaging provides a strong barrier against moisture and air, preventing leakage and maintaining the integrity of the product inside. The tin coating on the steel surface ensures excellent corrosion resistance, enhancing the packaging's ability to protect against leaks. Additionally, tinplate packaging is highly durable and able to withstand external pressures, reducing the risk of package damage that could lead to leakage. Overall, the use of tinplate packaging significantly contributes to product protection and helps prevent leakage.

- Q: How is tinplate coated with organic materials for specific applications?

- Tinplate is coated with organic materials for specific applications through a process called organic coating or lacquering. The tinplate is first cleaned and prepared to ensure proper adhesion of the organic coating. Then, a layer of organic material such as epoxy, polyester, or acrylic resin is applied to the tinplate surface using various methods like coil coating or spray coating. This organic coating provides protection against corrosion, enhances the tinplate's appearance, and allows for customization based on specific requirements of the application.

- Q: What are the advantages of using tinplate for cosmetic packaging?

- There are several advantages of using tinplate for cosmetic packaging. First, tinplate is highly durable and provides excellent protection to the cosmetic products, ensuring their integrity during transportation and handling. Second, tinplate is resistant to corrosion and can withstand moisture, which is crucial for preserving the quality and shelf life of cosmetics. Third, tinplate is a sustainable packaging option as it is 100% recyclable and can be reused multiple times, reducing the environmental impact. Lastly, tinplate offers a premium and attractive appearance, enhancing the overall aesthetic appeal of cosmetic packaging and leaving a positive impression on consumers.

- Q: What is the average lifespan of tinplate products?

- The average lifespan of tinplate products can vary depending on several factors, such as the quality of the tinplate used, the conditions in which the products are stored and used, and how well they are maintained. Generally, tinplate products can last for several years to a decade or more if properly cared for.

- Q: Can tinplate be used for promotional and gift items?

- Yes, tinplate can be used for promotional and gift items. It is a versatile material that can be easily customized and printed on, making it ideal for creating unique and eye-catching promotional merchandise or personalized gifts. Tinplate items such as tin boxes, tin cans, or tin signs can be branded with logos, messages, or designs, making them an excellent choice for promotional and gift purposes.

- Q: How is tinplate affected by exposure to moisture?

- Tinplate is highly susceptible to corrosion when exposed to moisture. The presence of water triggers a chemical reaction, causing the tin coating to deteriorate and exposing the underlying iron to oxidation. This can result in rust formation and compromise the integrity of the tinplate. Therefore, it is crucial to protect tinplate from prolonged exposure to moisture to ensure its longevity and prevent potential damage.

- Q: What are the main applications of tinplate in the music industry?

- Tinplate is primarily used in the music industry for the production of musical instrument components, such as guitar picks, harmonica reeds, and various percussion instruments. Its corrosion resistance and durability make it an ideal material for ensuring consistent sound quality and longevity of these instruments. Additionally, tinplate is also utilized for the packaging of musical media, such as CDs and vinyl records, providing a protective and attractive casing for music albums.

- Q: Is to buy canned tinplate or aluminum

- Tinplate, our company sells tinplate

- Q: How does tinplate packaging contribute to product protection during shipping?

- Tinplate packaging provides effective protection during shipping due to its durability and strength. It acts as a sturdy barrier against external elements, such as moisture, light, and air, which can potentially damage the product. Tinplate packaging also offers resistance to corrosion, ensuring the product's integrity throughout the shipping process. Its robust construction provides cushioning and prevents the product from being easily crushed or dented. Overall, tinplate packaging plays a crucial role in safeguarding the product from various risks, ensuring it reaches the destination in optimal condition.

- Q: How does tinplate contribute to the preservation of paint products?

- Tinplate contributes to the preservation of paint products by providing a durable and protective packaging material. Its corrosion-resistant properties prevent the paint from coming into contact with air and moisture, which can degrade its quality over time. Additionally, tinplate's ability to withstand high temperatures and impacts ensures that the paint remains intact during transport and storage, maintaining its freshness and longevity.

Send your message to us

Printing Tinplate Coils With Prime Quality for 0.29mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords