Plastic Sheets - Printing PVC Celuka Sheet/PVC Foam Core with Die Cutting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

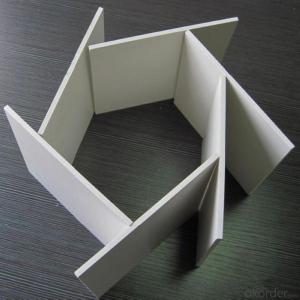

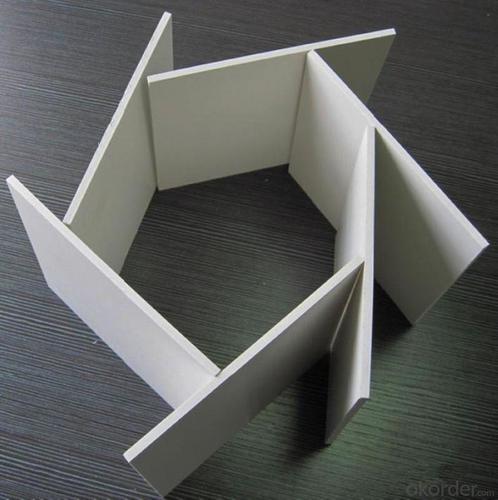

PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

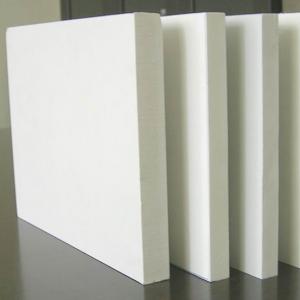

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

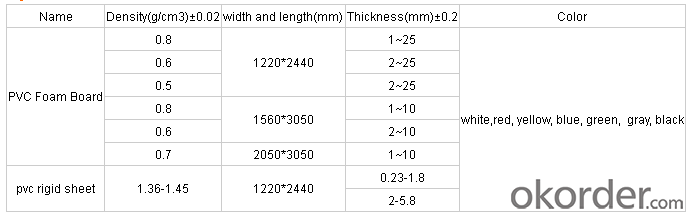

Product Specification

Regular size: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness:1-33mm

Density:0.43- 0.9mm

Product Features

1.Waterproof, fireproof retardant, moistureproof, anticorrosive, Weather resistant, moth-proofing, anti cracking, anti UV.

2.Less warping, stand wear and tear, acid and alkali resistance, easy coloring, no glue and paint

3.Can be nailed, drilled, shaved, chiseled, riveted, With wood properties and better than wood, color diversity

4. Safety and environmental protection, formaldehyde-free

5. Easy to install, easy to clean, easy to maintain

Product Application

(1)Advertising: exhibition display, digital printing, silk screen printing, computer lettering, sign board, light box, etc.

(2)Construction: office and bathroom cabinets, inner and outer decorate panel, commercial decorating shelf, room separating

(3)Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layer and other industry.

Application fields | The specific application |

Household furniture | tables , chairs , benches , stools – furniture, Sofa, Box spring, Bookshelf, clothing case, tea table, screen, frame, handle, plate, bar, newspaper rack. |

Construction | Mobile home, window frame, door plank, threshold, template, concrete stairs clap, wallboard, ceiling, floor, and various profiles, etc |

Industrials | Chemical corrosion barrack and public places, decorating plate, floor, channel, bench, and the casting model, the machine cover, pump shell, electrical materials, etc |

........ | |

FAQ

3. Advantages of your products?

Answer :Company products, good quality, high reputation guarantee.

4. Are you a factory manufacturer or a trade company?

What are your product ranges? Where is your market?

Answer :we are manufacturer specializing in stationery and plastic packing products in highly quality and competitive price with over years,such as file folder,file bag,gift bag,closet organizer ,packages of cosmetic and other daily necessities, they are mainly famous ,such as USA, AUSTRILA, CANADA,EUROPE ,MIDDLE EAST,SOUTHEAST ASIA AND SO ON.

More Details of Product

- Q: How do plastic sheets compare to polycarbonate sheets?

- Plastic sheets and polycarbonate sheets have some similarities, but there are also significant differences between the two materials. Plastic sheets refer to a broad category of materials such as acrylic, PVC, or HDPE, while polycarbonate sheets are a specific type of plastic sheet. In terms of strength and durability, polycarbonate sheets outperform most traditional plastic sheets. Polycarbonate is known for its exceptional impact resistance, making it virtually unbreakable. On the other hand, regular plastic sheets may be more prone to cracking or breaking under stress. Another significant difference is transparency. Polycarbonate sheets are generally more transparent than most plastic sheets, allowing for clearer visibility. This trait makes them suitable for applications where optical clarity is crucial, such as in windows or protective barriers. However, plastic sheets have their own advantages. They are often more cost-effective compared to polycarbonate sheets, which can be a significant factor in certain projects or applications. Additionally, plastic sheets come in a wider range of colors and finishes, allowing for more design options. Ultimately, the choice between plastic sheets and polycarbonate sheets depends on the specific requirements of the application. If strength, impact resistance, and optical clarity are top priorities, polycarbonate sheets are the preferred choice. However, if cost, color options, or specific material properties are more important, traditional plastic sheets may be a viable alternative.

- Q: What happens if a clear lenticular (autostereoscopic) sheet is cut to size and placed over a 26 hdtv screen? Is there any type of 3D effect? (These type sheets are commonly used on greeting cards/trading cards/wall posters for a 3D-depth effect.) Thanks

- It wouldn't work as the picture underneath needs be printed in a special way too.

- Q: I got a protective plastic sheet, but every time I try to put it on, a million bubbles keep popping out.

- Unfortunately, it's not really possible to eliminate every bubble. Just put it on very slowly and try to rub them out as you go instead of trying to get them all at the end. Keep in mind that when the iPod is turned off, the bubbles look horrible but once it's turned on, you won't notice them nearly as much.

- Q: Computer cases have clear side panels, what is it called plastic sheet?

- perspex but if you're insterested there's an awesome case that comes with all that. tha antec nine hundred check that out while you're looking

- Q: POM what's the plastic board for?

- POM is the abbreviation of paraformaldehyde. It is a new kind of fine resin developed after nylon. It has good comprehensive properties.

- Q: i jut bought some playboy bed sheets and was wondering how long they might last they are of a satin silky material but obviously not real silk. if i wash them once a week how long willl they last

- Satin is polyester, which is woven plastic. If the sheets do not develop snags, they should last for many years. Plastic is tough stuff. Hope this helps. -

- Q: How do plastic sheets compare in cost to other materials?

- Plastic sheets generally tend to be more cost-effective compared to other materials.

- Q: do that.

- Because they have not taken high quality photos of that region ~

- Q: Can plastic sheets be used for insulation against heat or cold?

- Yes, plastic sheets can be used for insulation against both heat and cold. They have low thermal conductivity, which helps to reduce the transfer of heat or cold between two spaces. Additionally, plastic sheets can be effective in preventing air infiltration, further enhancing their insulating capabilities.

- Q: I got, what I thought was a great deal on photo albums. When I got them home, I discovered they are only plastic envelope type pages. After reading the covers on the albums, it says clearly says sheet protectors, so what do I need to purchase to stick my pictures on to put into these plastic sheets?I am new at scrapbooking and photo album placements!!!!

- photo almum placments have a stronger plastic. or no plastic at all. And the other is more like... plastic plage protectors and more flimsy. im not to sure, but thats what i suppose. look it up in google?

Send your message to us

Plastic Sheets - Printing PVC Celuka Sheet/PVC Foam Core with Die Cutting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords