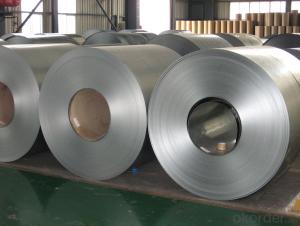

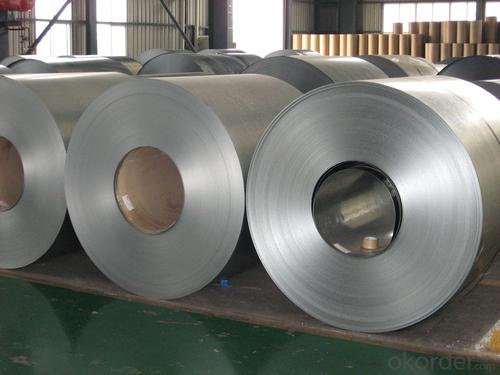

Prime Quality Hot Dip Galvanised Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Dipped Galvanized Steel Coil

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Product Description Of Hot Dipped Galvanized Steel Coil

Thickness | 0.13mm-0.7mm |

Width | 600mm-1250mm |

Zinc Coating | 30-200g/m2 |

Internal Diameter | 508mm/610mm |

Coil Weight | 3-12MT |

Quality | commercial and structural quality |

Surface Treatment | regular & minimum spangle, zero spangle, oiled & dry, chromated , non-skin pass , skin pass |

Standard | JIS G 3302, ASTM A 653M, EN 10327 |

Steel Grade | SGCC, CS, FS, SS, LFQ, DX51D+Z , S280GD |

Technical Data Of Hot Dipped Galvanized Steel Coil

Chemical Composition | C | Si | Mn | P | S |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% | 0.006%-0.009% |

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Out-of-square | not exceed 1% Flatness |

Bow | 15mmmax |

Edge Wave | 9mmmax |

Centre Buckle | 8mmmax |

Bending At 180 Degree | No crack, purling and fraction |

Application Of Hot Dipped Galvanized Steel Coil

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making roofing tile, steel profiles for wall partition, T-bar, studs, fireproof door, air conditioning duct and home appliance.

- Q: I got my dog those nice looking stainless steel water and food bowls (looks great next to my kitchen appliances...haha). The thing is my dog will drink from the toilet or a plastic bowl but not out of his bowl...I was wondering if those stainless steel bowls change the taste of food and water?

- Well, I know the water at this restaurants where they use metal pitchers taste a bit off to me. There's nothing wrong with the water, but I think the metal pitcher throws off the flavor. Could be the same with the metal bowl and the dog. Plastic is only a problem at hiding bacteria if it gets scratched up badly (which isn't as likely to happen with water as long as the dog doesn't chew it. You can also put the plastic crock bowls on the top shelf of a dishwasher for cleaning as the heat kills most germs.

- Q: i mean cor ten steel( rusted)

- If the steel is true Cor Ten steel, it does not require waxing. Cor Ten is a steel designed to rust slowly over time ... then the rust acts as a natural barrier to prevent further rust. Check out the United States Steel building in downtown Pittsburgh, PA ... its nickname is The Rusty Nail.

- Q: How do steel coils contribute to corrosion resistance in products?

- Corrosion resistance in products is achieved through a combination of factors provided by steel coils. Firstly, the coils are typically constructed from stainless steel, which contains a high concentration of chromium. This chromium forms a passive film on the steel's surface, acting as a protective oxide layer that prevents corrosion. Furthermore, this film possesses the ability to self-heal, regenerating itself if damaged or scratched, thereby ensuring continuous corrosion protection. In addition, the steel coils undergo a process known as galvanization, which involves applying a layer of zinc to the steel's surface. This zinc layer functions as a sacrificial anode, corroding preferentially to the steel. This sacrificial corrosion shields the underlying steel, effectively preventing the formation of rust and other types of corrosion. Moreover, steel coils can be coated with various protective materials like epoxy or polyurethane to enhance their corrosion resistance. These coatings act as an additional physical barrier, preventing moisture, chemicals, and other corrosive elements from reaching the steel surface. Lastly, steel coils can be manufactured with specific alloying elements such as nickel or molybdenum, further enhancing their resistance to corrosion. These alloying elements bolster the strength and durability of the steel, enabling it to withstand harsh and corrosive environments more effectively. In summary, steel coils contribute to the corrosion resistance of products by utilizing stainless steel, galvanization, protective coatings, and alloying elements. The implementation of these measures ensures that products retain their structural integrity and appearance over time, even under demanding and corrosive conditions.

- Q: i want to know if i should buy a set of acrylic tapers or steel. they r close in cost so it's not a money factor i want to know which work better and if there is a downside to either. thanks!

- It relies upon on your physique and what you desire. in case you physique is allergic to a minimum of one in all them you may would desire to chosen for yet another one. If this is not any longer allergic to any, than you need to use in spite of you like the main, in simple terms attempt the two.

- Q: If a make a dish antenna of steel and of fiberglass, which would be more heavy and also which would be more expensive?

- Steel will be heavier but easier to manufacture. There won't be a huge weight advantage because you can use steel mesh which works the same as solid, near enough, as an electromagnetic reflector. Steel can just be pressed, fiberglass has to be laid up of resin and mat and then allowed to cure. Fiberglass will also need to be coated in something conductive whereas you can just spray paint the steel, or even buy it pre-coated.

- Q: so my parents gave me stainless steel cookware for christmas and the first time i used it i cooked chicken. it stuck to the pan and where the oil splattered it cooked on and turned it dark black and brownish. and the bottom too. i don't cook with it because i don't want to burn it on anymore but i don't know how to clean it. how do i cook without burning anything, aside from a lower flame and how on earth do i get the stains on. i've tried almost everything too! thanks.

- I, too, don't like stainless steel because it is so hard to keep clean. Bar Keeper's Friend really does become your friend when you cook on stainless steel. It will remove the burnt on food, remove the dark brown stains and keep it looking new, however. And, it won't void most manufacturer's warranties on the cookware. It just takes the elbow grease to do it every time you use it. I found it is necessary to use more olive oil than you think is necessary, a lower flame than most recipes call for and a lot of patience if you plan to use it on a daily basis. I went back to my non-stick Calphelon because I am not a patient woman, I like instantaneous gratification and hate scrubbing pots and pans!

- Q: Can steel coils be used in structural applications?

- Yes, steel coils can be used in structural applications. Steel coils are often processed into various shapes and forms, such as beams, columns, or plates, to provide structural support and strength in construction projects. The use of steel coils ensures durability, load-bearing capacity, and resistance to deformation, making them suitable for structural applications in buildings, bridges, and other infrastructure projects.

- Q: What are the common surface treatments for galvanized steel coils?

- Galvanized steel coils can undergo various surface treatments to improve their corrosion resistance and appearance. Passivation is one such treatment, where a protective material like zinc phosphate or chromate is applied to create a barrier against moisture and atmospheric elements. This also enhances the adhesion of subsequent coatings or paints. Another treatment is chromate coating, which involves applying a thin layer of chromate to the steel surface. This provides extra protection against corrosion and enhances the steel's appearance. Chromate coatings can be clear or colored, depending on the desired aesthetic. Oiling is a common treatment that involves applying a thin layer of oil to prevent rust and corrosion during storage and transportation. It also offers temporary protection against moisture and other environmental factors until the steel is further processed or used. These surface treatments are widely used to improve the performance, durability, and appearance of galvanized steel coils, ensuring they can withstand harsh conditions and maintain their quality over time.

- Q: How are steel coils used in the manufacturing of metal structures?

- Steel coils are used in the manufacturing of metal structures as they provide a convenient and efficient way to shape and form steel into various components. These coils are often processed through rolling mills to produce sheets or plates, which can then be cut, bent, or welded to create structural elements such as beams, columns, and trusses. The use of steel coils ensures uniformity, strength, and flexibility in the manufacturing process, allowing for the production of durable and reliable metal structures.

- Q: I have been wanting a new pair of hiking boots, but haven't had the money. I just got a job that requires me to have steel toed boots. The job is only for a few weeks, but I may be required to wear them on other jobs in the future. Regardless of which style I get, I will most likely be buying Red Wing boots. On their website, I see they have steel toed hiking boots. What is the purpose of a steel toed hiking boot? Why would a hiker need to have steel toed boots? Wouldn't that just be more weight? I see that some of their hiking boots have aluminum toes, claiming to be 33% lighter than steel with the same protection. Would these boots be good potential hiking boots as well as suitable for construction or should I just focus on work boots and buy myself some hiking boots at a later date?

- Steel toed boots is a safety factor thing. Wilderness workers ie lumber jacks need safety shoes as well. But for long distance hiking steel toed shoes would be impractical due to the weight and wear and tare on The trails and your body. Get the boots you need for work, get the hiking boots you want after the next paycheck.

Send your message to us

Prime Quality Hot Dip Galvanised Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords