Galvanized Steel Coil/GI in High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

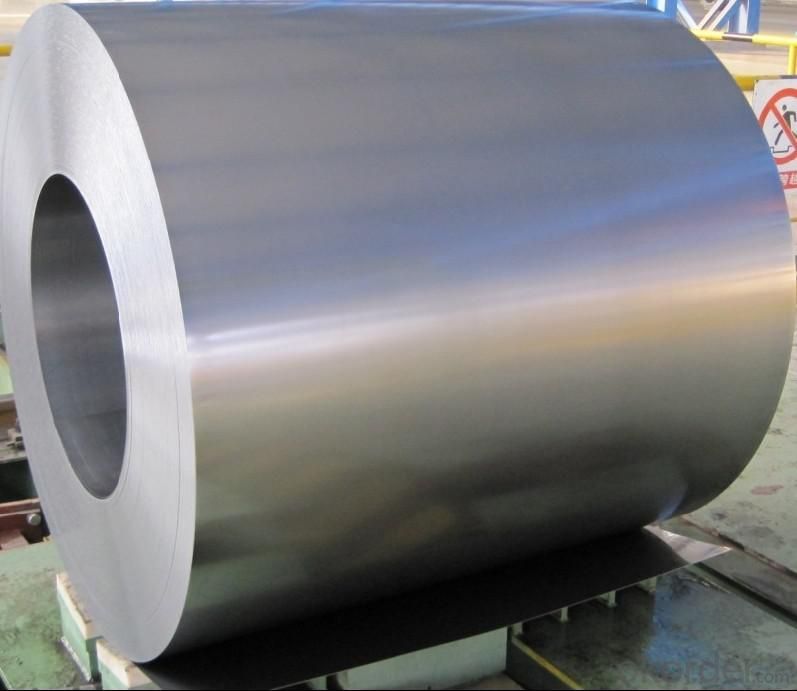

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

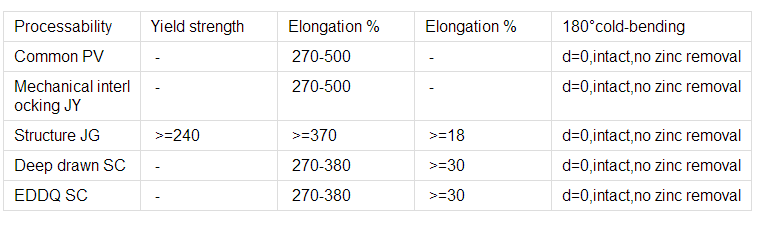

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What are the main factors to consider when selecting a steel coil supplier?

- When selecting a steel coil supplier, the main factors to consider include the supplier's reputation and reliability, the quality of their products, their pricing and payment terms, their delivery options and lead times, their customer service and support, as well as their ability to meet your specific requirements and specifications.

- Q: How are steel coils cut and shaped for specific requirements?

- Steel coils are cut and shaped for specific requirements through a process called slitting and forming. Slitting involves unwinding the coil and passing it through a set of circular blades that cut it into narrower strips. These strips can then be further processed through different forming techniques such as roll forming, stamping, or bending to achieve the desired shape and dimensions. This allows manufacturers to customize steel coils according to specific requirements for various applications in industries like automotive, construction, and manufacturing.

- Q: How do steel coils contribute to the transportation industry?

- Steel coils contribute to the transportation industry by being used to manufacture various components and structures for vehicles, such as the body frames, chassis, and suspension systems. These coils are also used in the production of shipping containers, railcars, and cargo ships, ensuring the safe and efficient transportation of goods across different modes of transport.

- Q: How are steel coils inspected for width?

- Steel coils are inspected for width using various methods to ensure they meet the required specifications. One common method is to use a caliper gauge, also known as a micrometer, which measures the width of the coil by physically contacting its edges. The operator places the caliper gauge at various points along the width of the coil and records the measurements. This method allows for precise measurements and helps identify any inconsistencies or deviations from the desired width. Another method used for inspecting steel coil width is laser measurement. Laser sensors are positioned on both sides of the coil, and they emit a laser beam that scans across the width of the coil. The sensors detect the distance between the coil's edges and provide accurate width measurements. This non-contact method is highly efficient and can quickly inspect the width of the coil without any physical contact or potential damage. In addition to these methods, some advanced systems use computer vision technology for width inspection. Cameras and image processing software are employed to capture images of the coil's edges. The software analyzes these images and calculates the width based on the detected edges. This method allows for high-speed inspections and can detect any irregularities in the width of the coil. Overall, steel coils are inspected for width using a combination of physical gauges, laser sensors, and computer vision technology. These methods ensure that the coils meet the required width specifications and help maintain quality control in the steel manufacturing process.

- Q: So, I'm doing this project for my chemistry class and I need to explain the raw materials in which paper slips are made of. I'm not really sure if galvanized steel is. If not, can someone PLEASE tell me what raw materials are metal paper clips made of???

- No, because first of all galvinizing is coating the steel with zinc to prevent oxidation. Iron is a raw material, as is zinc, carbon. Other metals may be combined with the iron and carbon, including vanadium and chromium.

- Q: Steel Strings on your guitar or nylons? Why?

- Steel because I bought a steel string guitar and that's what goes on it. Had I bought a classical guitar I would put nylon strings on it, but I don't particularly want to play classical guitar music, so I bought a steel string guitar. That's my story and I'm stickin' to it!

- Q: I know there is soft steel and sturdier steel they use in products. The sturdier often used for equipment that requires more durability when in operation.

- Some steel won't 'harden' very much to begin with. Mild steel found commonly around the shop/farm/house has few alloys other than carbon, and may not get the desired hardness no matter what you do. A quick test to see what type you have (mild steel vs. alloy) is to touch it to a grinding wheel.

- Q: How do steel coils contribute to the water and wastewater industry?

- Steel coils contribute to the water and wastewater industry by being used in the construction of pipes, tanks, and other infrastructure. These coils provide strength, durability, and corrosion resistance, ensuring the integrity and longevity of water and wastewater systems. Additionally, steel coils are often utilized in the manufacturing of water treatment equipment and machinery, helping to improve the efficiency and effectiveness of the water and wastewater treatment processes.

- Q: I'm searching for the elastic modulus of ASTM A653 galvanized steel sheet. Max points for first person with a response that includes web address of reliable reference - I just haven't found it yet. thanks!

- I've okorder /

- Q: What is the material of steel coil 08F and what brand can be used instead?

- The high quality carbon structural steel, carbon steel, steel commonly referred to as. Steel for the manufacture of parts for various machines.1.08 and 08F steel is used for rolling thin plates, deep drawing products, oil drums and high-grade enamel products. It can also be used for the manufacture of pipes, gaskets and core parts with low strength requirements, carburizing and cyaniding parts, welding electrodes and so on.2.10 and 10F steel, use cold pressing deep drawing products below 4mm, such as deep drawing vessel and shell. It can also make boiler tubes, oil drum covers and steel strips, steel wires, welding pieces and mechanical parts.3.15 and 15F steel are used to make carburizing parts, fastening parts, die forging parts and low load parts without heat treatment, such as bolts, screws, flanges and storage tanks for chemical machinery, steam boilers, etc..

Send your message to us

Galvanized Steel Coil/GI in High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords